Piping Controllers_NC200

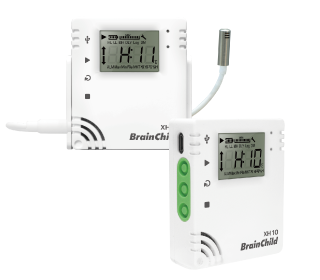

The NC200 is a compact fuzzy logic plus PID temperature controller with J or K type thermocouple or RTD input. Multiple units (up to 247 units) can be networked together with 4P4C modular connector. Each unit auto-tunes on initial setup to provide the best response for each heater. The NC200 is powered by 90-250VAC supply and contains a solid state relay as its control output. The solid state relay can drive the heater directly through a plug-in connector. The major

features of the unit are as following:

- COMPACT SIZE

- EASY INSTALLATION

- SELF ADDRESSING

- FAST COMMUNICATION SPEED

- Auto addressing, manual setting unnecessary

- Network up to 247 controllers

- The fastest speed, taking 1 second to update 1000 data

- Used with SCADA, HMI via Modbus RTU

- Quick connector for easy and safe wirings

| Power |

|---|

| 90 ~ 250 VAC, 47 ~ 63 Hz, 800VA maximum |

| INPUT: | |||

|---|---|---|---|

| Type | Range | Accuracy | Input Impedance |

| J | -17.8°C ~ 500 °C ( 0°F ~ 932 °F ) |

±2 °C | 1MΩ |

| K | -17.8°C ~ 500 °C ( 0°F ~ 932 °F ) |

±2 °C | 1MΩ |

| PT100 (DIN) | -17.8°C ~ 500 °C ( 0°F ~ 932 °F ) |

±1°C | 1.3KΩ |

| Output (Solid state relay) | |

|---|---|

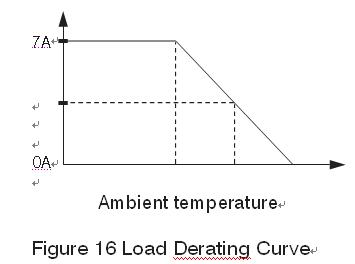

| Relay Rating : 7A @25 C, 3.5A @47.5 C ambient temperature, 90 ~ 250 VAC, 47 ~ 63Hz. See Fig.16 Load derating curve Switch ON-OFF: Zero crossing triggering Insulation resistance: 1000 Mohms min. at 500 VDC Dielectric strength: 2500 VAC for 1 minute. |

|

| Data Communication | |

|---|---|

| Interface | RS-232 ( 1 unit ), RS-485 ( up to 247 units ) |

| Protocol | Modbus Protocol RTU mode |

| Address | 1 - 247 |

| Baud Rate | 2.4 ~ 38.4 Kbits/sec |

| Parity Bit | None, Even or Odd |

| Stop Bit | 1 or 2 bits |

| Communication Buffer | 64 bytes |

| Control Mode | Action Reverse (heating) |

|---|---|

| PID mode | PB= 1-500 °C TI= 1-900 sec. TD= 0-300 sec. |

| Cycle time | 2 seconds |

| Manual control | 0-100% |

| Auto-tuning | Cold start and warm start |

| Power limit | 0-100% |

| Environmental & Physical | |

|---|---|

| Operating Temperature | -10°C ~ 50°C |

| Storage Temperature | -40°C ~ 60°C |

| Humidity | 0 ~ 90 % RH ( non-condensing ) |

| Altitude | 2000m maximum |

| Insulation Resistance | 20 Mohms min. ( at 500 VDC ) |

| Dielectric Strength | 1350 VAC, 50/60 Hz for 1 minute |

| Vibration Resistance | 10 - 55 Hz, 10 m/s² for 2 hours |

| Shock Resistance | 200 m/s2 ( 20 g ) |

| Dimensions | NC200 --- 50.3(W) x 52.4(L) x 45(H) mm |

| Weight | 112 grams |

| Approval Standards | |

|---|---|

| Safety | EN61010-1 |

| Protective Class | IP 20 |

| EMC | EN61326 |

| Documentation | ||

|---|---|---|

| User Manual | UMDL200B (151.55 KB / 2pages ) | Download |

| User Manual | UMNC200B (87.82 KB / 2pages ) | Download |

Plastic/rubber industry

It is installed on the heating material tube of the injection molding machine to control the temperature of the raw material, effectively control the liquid temperature of the plastic and improve the molding quality of the product.

Installed on the hot runner system for temperature control of runners and gates to stabilize the quality of the plastic.

Temperature control on the mold temperature machine, indirectly adjusting the temperature of the mold by adjusting the temperature of the hot fluid, can improve the production efficiency of the product and reduce the generation of defective products.

Electric heating furnace industry

Vacuum furnace equipment / vacuum melting / vacuum heat treatment

A new algorithm for PID adjustment using fuzzy rules is used to adjust the PID algorithm to eliminate the PID saturation integral phenomenon when the error is large. When the error is small, the improved PID algorithm is used for adjustment and can be automatically adjusted. Learn and memorize some of the characteristics of the controlled object to optimize the effect

Semiconductor industry

The temperature control of the electric heating cloth package is often used for the heating of the exhaust pipe valve parts of the semiconductor factory, the panel factory, or the special steel cylinder.

In the semiconductor temperature process control program, the heating system of the chamber, such as the decane process, the dichloromethane process

Ceramic / kiln / glass industry

Ceramic sintering furnace:

The heating process on the sintering furnace controls the heating rate to obtain a finished product with better quality and stability.

Electric kiln:

Temperature adjustment during kiln firing to obtain a finished product with better quality and stability.

Fiber machinery

Dyeing machine:

control the temperature during dyeing to a suitable range, which in turn reduces chromatic aberration and improves the quality of dyed products.

Fiber dryer:

The temperature during drying is controlled within a suitable range to improve the fiber product.

other

Ver. 1.02

Temperature Controller

Constant temperature and humidity machine

Heating/cooling air conditioning

Pool/bathroom temperature control facility

| NC200 - | □ | □ | □ | □ |

| 1 | 2 | 3 | 4 |

| 1 Power Input | 4: 90 ~ 250 VAC, 47-63 HZ |

| 2 Signal Input | 1: Standard Input Thermocouple: J, K RTD: PT100 DIN 9: Special Order |

| 3 Control Output | 3: Solid State Relay, 3A/250VAC |

| 4 Options | 0: °C 1: °F |

| Standard ordering code = NC200-4130 |

.png)