STEP 01

Initial Audit

Establishing the Foundation

Both parties conduct an initial assessment of product requirements, functional specifications, and application conditions. Technical feasibility and collaboration potential are evaluated to build a solid foundation for subsequent development.

STEP 02

Development

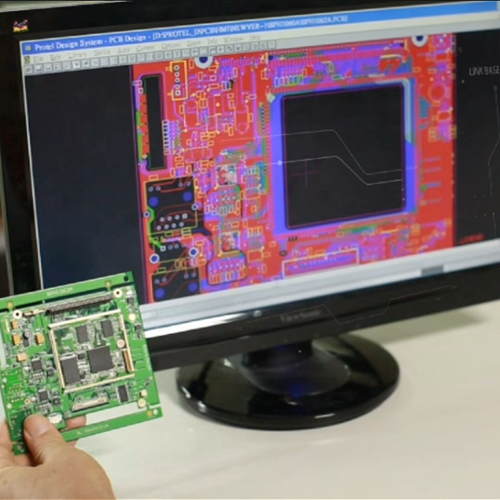

Technical R&D

We develop hardware and system functions based on customer requirements, ensuring stable performance and production-friendly design.

Collaborative Teamwork

The project manager coordinates R&D, production, and engineering tasks to ensure smooth execution and on-time delivery.

STEP 03

Prototype Testing

Function Testing

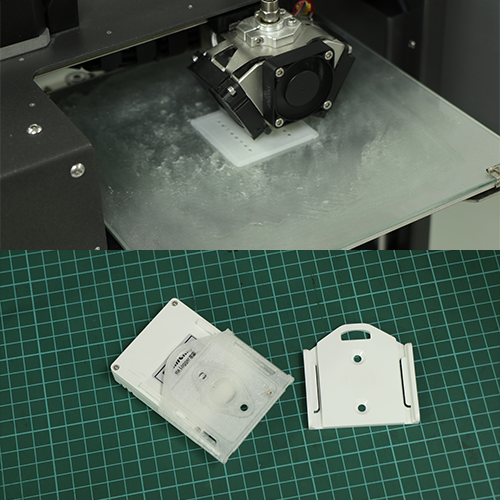

Functional prototypes are built according to design specifications and tested through simulations to ensure core performance and reliability. The resulting data provides a foundation for further refinement and mass production readiness.

Rapid Prototype Delivery

With over 45 years of R&D and manufacturing experience, we rapidly deliver samples that closely resemble the final product. This speeds up validation and facilitates a smoother transition into mass production.

STEP 04

Certification

In-House Testing Capability

Our in-house R&D lab is equipped to perform various tests, including CE-related evaluations. This enables us to ensure compliance with market standards early in the development stage, laying the groundwork for smooth certification and product launch.

Certification Support Service

For customers requiring formal certifications, we provide support based on the product’s application and target markets. We assist in completing the necessary certifications to ensure successful market entry.

STEP 05

Mass Production

Process Environment

Production is carried out in an ESD-compliant environment to ensure stable manufacturing quality of electronic products. Through rigorous process control and quality traceability mechanisms, overall product consistency and reliability are enhanced.

Smart Manufacturing

Automation equipment is implemented to improve production efficiency, allowing personnel to focus on quality and process optimization. The collaboration between machinery and manpower ensures a balanced fulfillment of delivery schedules, capacity, and yield rates.

STEP 06

Inspection

Test Delivery

Complete testing and quality verification are performed before shipment to ensure on-time delivery.