Textile manufacturing includes dyeing, drying, and finishing processes that require precise temperature and humidity control to ensure uniform dye adhesion, fabric texture, and dimensional stability. Stable environmental management during dyeing and drying reduces defects and improves product consistency. Equipment must support long-term continuous operation and real-time data monitoring to maintain process quality and production efficiency. Our high-precision temperature and humidity controllers and data recording devices empower the textile industry to enhance process automation and quality management.

Stenter Machine

The stenter machine plays a vital role in textile finishing processes, performing heat setting, drying, width control, and chemical fixation to improve fabric dimensional stability and surface quality.

By integrating a PID controller, the system provides precise multi-zone temperature and conveyor speed control, ensuring even heating across the fabric width. Tension controllers and synchronized motors help maintain uniform fabric movement and prevent distortion. The system can also include humidity sensors, exhaust control, and auto temperature regulation to optimize drying performance and energy efficiency. With a paperless recorder, key data such as temperature profiles, production speed, and energy consumption can be logged for traceability, process optimization, and energy audits—supporting higher product quality and smarter factory operations.

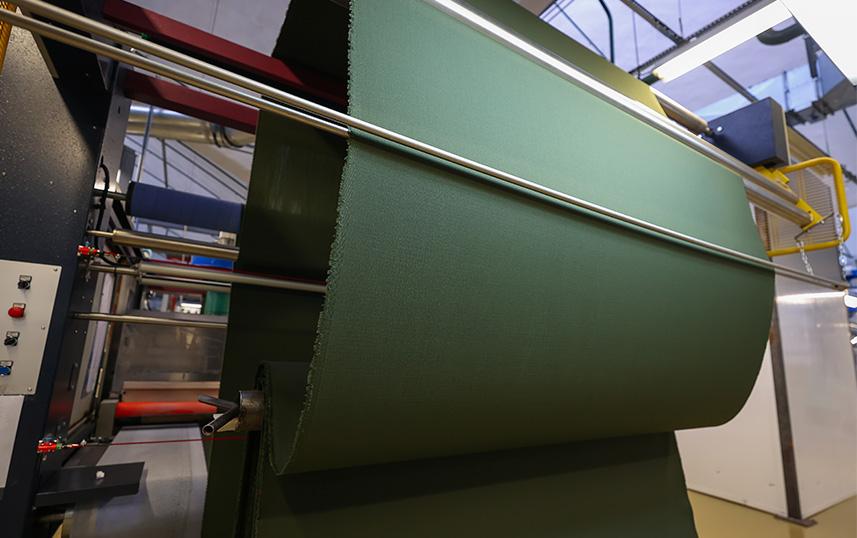

Dryer Machine

The dryer machine is a critical equipment in textile production, used to remove moisture from fabrics. By precisely controlling the heating element temperature and conveyor speed, it ensures uniform drying and improves downstream processing quality.

The system can be integrated with a PID controller to maintain stable heating temperatures while adjusting conveyor speed according to drying requirements. Temperature sensors and airflow control devices can be incorporated to enhance drying efficiency and reduce energy consumption. Paired with a paperless recorder, detailed records of temperature profiles, operating speeds, and energy usage can be maintained, facilitating production monitoring and energy management to improve product quality and operational efficiency.

Dyeing Machine

The dyeing machine is a critical piece of equipment in textile processing, used to uniformly color fabrics. By controlling the dye bath temperature, agitation speed, and dye liquor parameters, it ensures even dyeing and consistent quality.

The system can be integrated with a PID controller for precise ramp-up and ramp-down temperature control to facilitate proper dye-fiber reactions. Speed control of circulation pumps and agitators promotes uniform dye liquor distribution. Combined with pH and conductivity sensors and automatic dosing systems, it enables dynamic adjustment and injection of dyes and auxiliaries. Paired with a paperless recorder, the system records temperature profiles, pH values, and dosing times throughout the dyeing process, supporting traceability and quality control.