Features

- Built-in RS485 interface with Modbus RTU protocol

- Supports 5 alarm points with individual relays

- Supports thermocouple, RTD, mA, V, and mV inputs

-

18-bit A/D for high measurement accuracy

-

Analog output: 4–20mA / 0–10V

- 15-bit analog output resolution with ±0.05% accuracy

- Dual input channels with math (+, −, ×, ÷) functions

- 6 event inputs for alarm reset and external control

- Sampling rate up to 5 times per second (200ms)

- Supports Hi, Lo, Hi Latch, Lo Latch alarm modes

- EI forcing: force input display to max or zero

- Low Cut function displays zero when value drops

- Alarm relays rated 2A at 240VAC (resistive load)

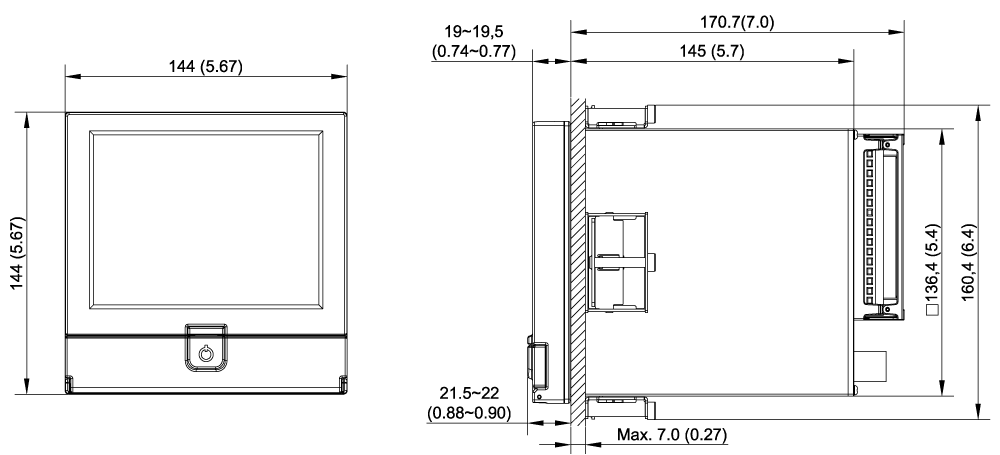

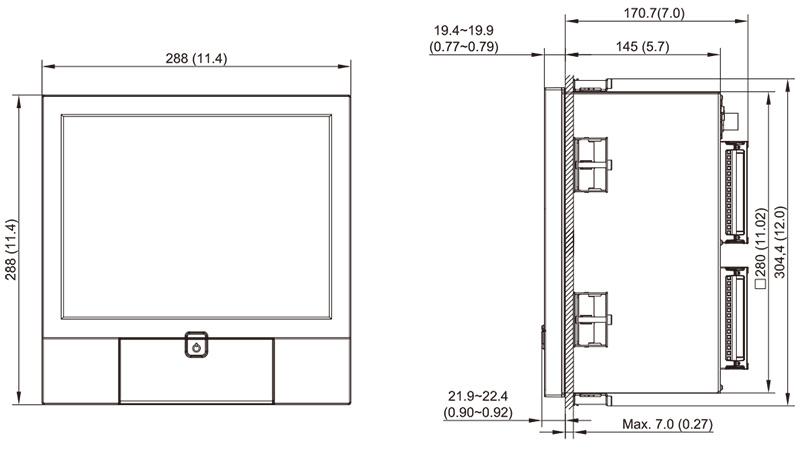

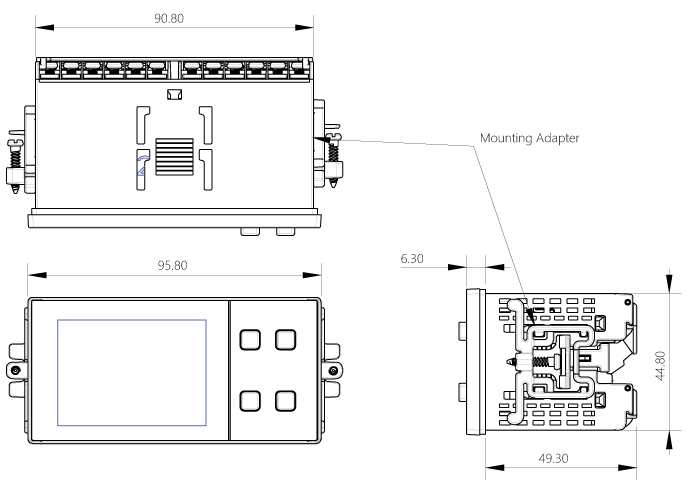

- Panel size 96×48 mm, standard 1/8 DIN format

- Wide-range power input: 90–250VAC or 11–40VDC

IA10 Indicator and Alarm Unit for Industry

Dual input, alarms, analog output, and Modbus RTU

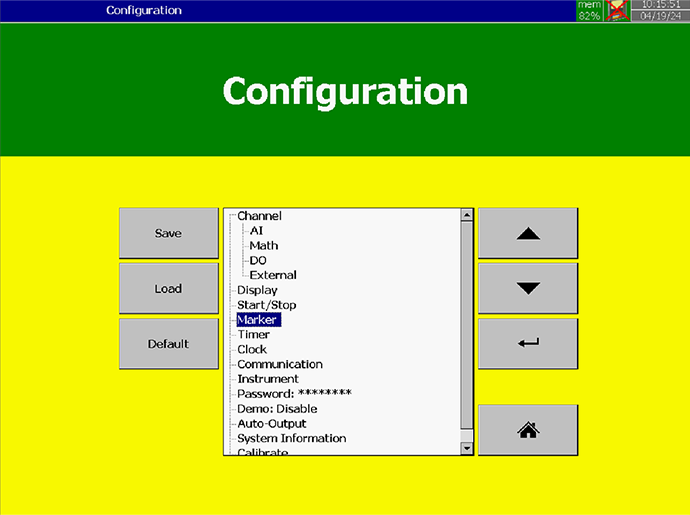

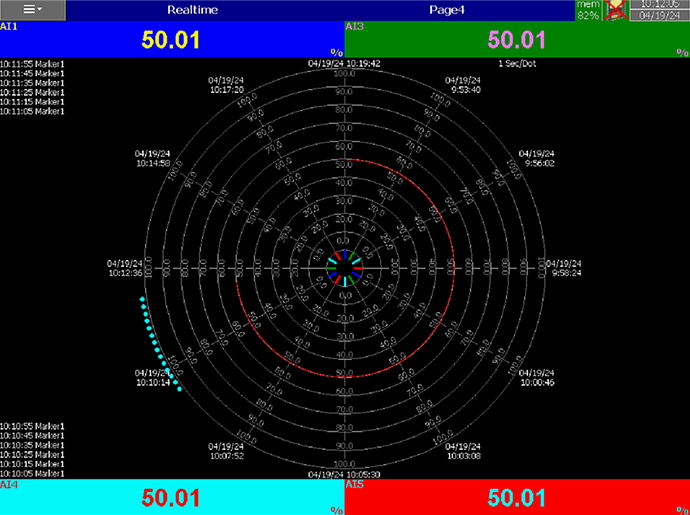

The IA10 Indicator and Alarm Unit is a high-precision industrial monitoring device designed for advanced process control. It features dual input channels with real-time arithmetic operations (+, −, ×, ÷), allowing precise data comparison and signal logic. IA10 supports thermocouples, RTDs, and analog inputs (mA, V, mV), making it ideal for applications like temperature, pressure, or flow monitoring.

With a tri-color LCD display, up to 5 alarm outputs, and 15-bit analog retransmission, IA10 delivers accurate visual feedback and secure alarm signaling. The unit also integrates Modbus RTU communication over RS485, ensuring seamless connectivity with PLC, SCADA, and remote systems. IA10 is built for reliability, integration, and performance in demanding industrial environments.

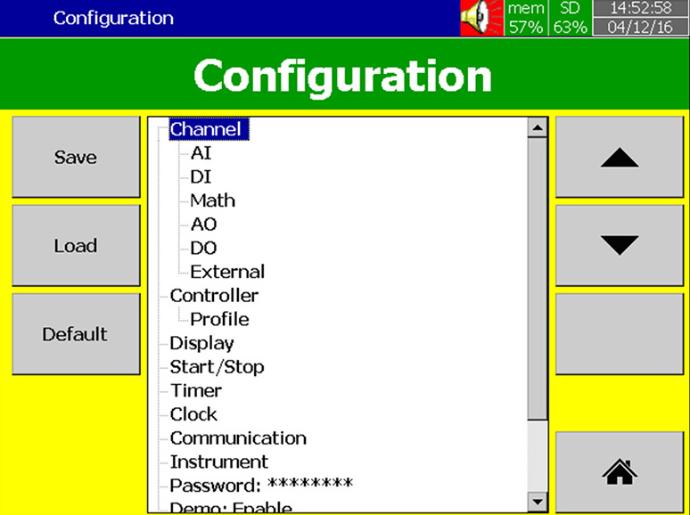

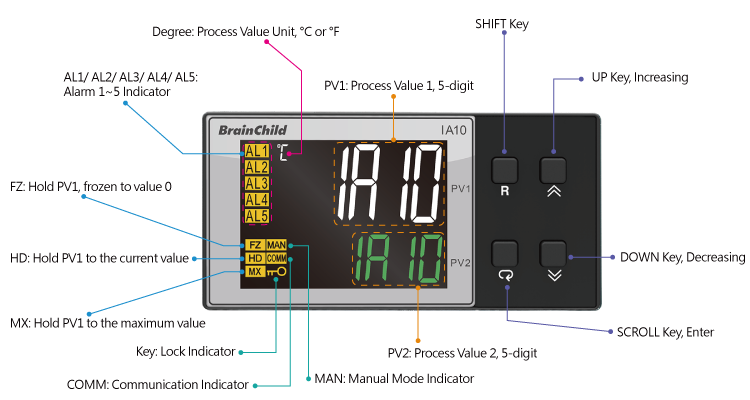

IA10 Panel Interface with Real Keys and On-Screen Indicators

Simple physical buttons with status shown on LCD screen

The IA10 front panel provides a clear and practical control interface using four real push buttons: SHIFT, UP, DOWN, and SCROLL (ENTER). These buttons support menu navigation, value editing, and setting confirmation—ideal for gloved use in industrial settings.

Unlike models with LED indicators, the IA10 displays operational states directly within its LCD screen, including alarms (AL1–AL5), manual mode (MAN), communication (COMM), key lock (KEY), and PV1 hold modes (FZ, HD, MX). This screen-based status system reduces mechanical parts and improves reliability.

A reset shortcut (SHIFT + SCROLL) lets users quickly return to the main screen. With intuitive layout and integrated status feedback, the IA10 ensures fast learning and secure operation in demanding environments.

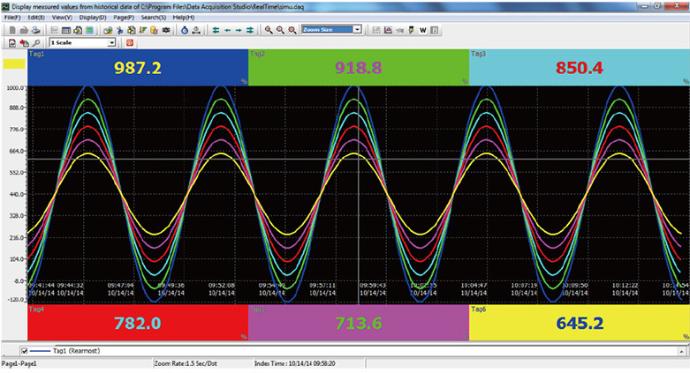

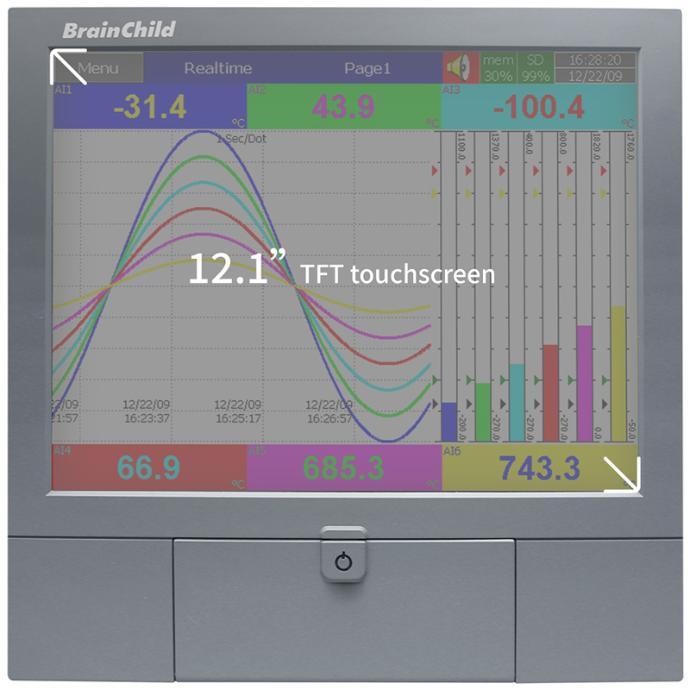

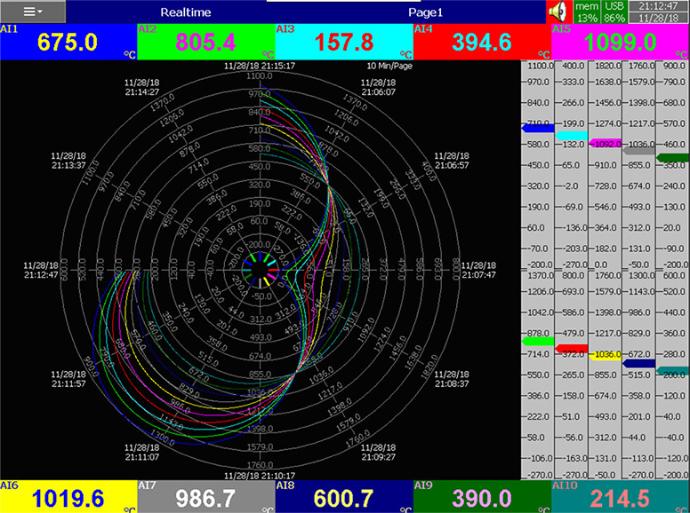

Clear and Structured LCD Display for Rapid Recognition

High-contrast screen layout ensures fast status identification

The IA10 features a high-contrast LCD screen with crisp character rendering and spacious layout, specifically designed to support quick visual recognition in demanding industrial environments. Both the main and secondary displays provide 5-digit resolution, making it easy to distinguish fine differences in process values at a glance.

Status indicators are logically grouped along the left edge of the display, separating them from numeric readings to avoid distraction. This information zoning makes alarm conditions and system modes instantly visible, even from wider viewing angles or under low-light conditions.

By optimizing layout clarity and visual hierarchy, the IA10's LCD screen minimizes reading errors and supports faster operator response during real-time monitoring.

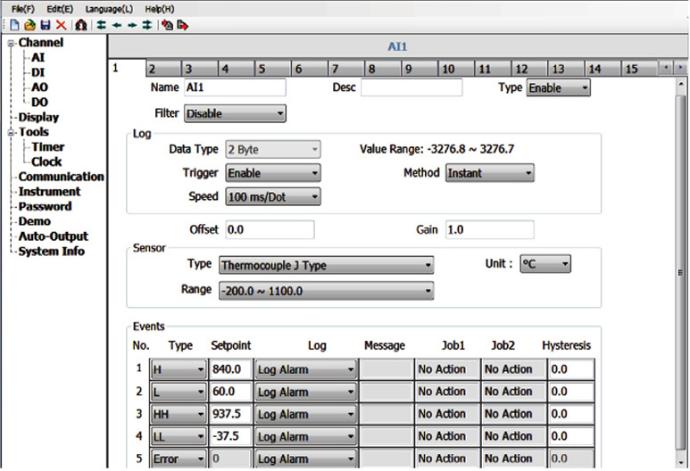

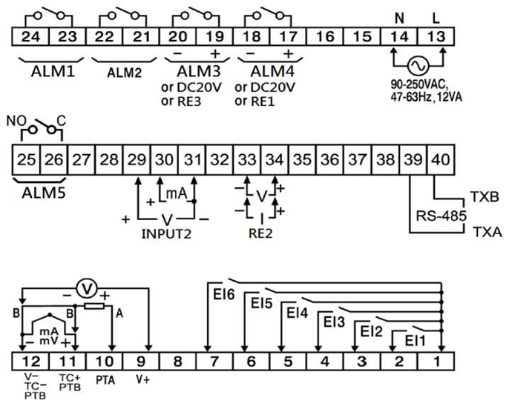

Dual Input Channels for Flexible Sensor Integration

Supports thermocouples, RTDs, and analog signals with independent scaling

The IA10 features dual input channels, allowing users to connect and monitor two separate sensor signals simultaneously. Input 1 supports a wide range of signal types including thermocouples (J, K, T, E, etc.), RTDs (PT100 DIN/JIS), and linear analog inputs such as 4–20mA, 0–10V, and mV levels. Input 2 is available as an option and supports additional linear current or voltage signals.

Each input channel is independently configurable, with selectable scaling ranges, engineering units (°C, °F, PU), and decimal resolution. This makes IA10 ideal for applications requiring temperature-to-pressure comparison, dual-zone control, or sensor redundancy.

The flexible input design enhances compatibility with a wide range of industrial sensors, reducing hardware complexity while increasing integration efficiency across diverse monitoring systems.

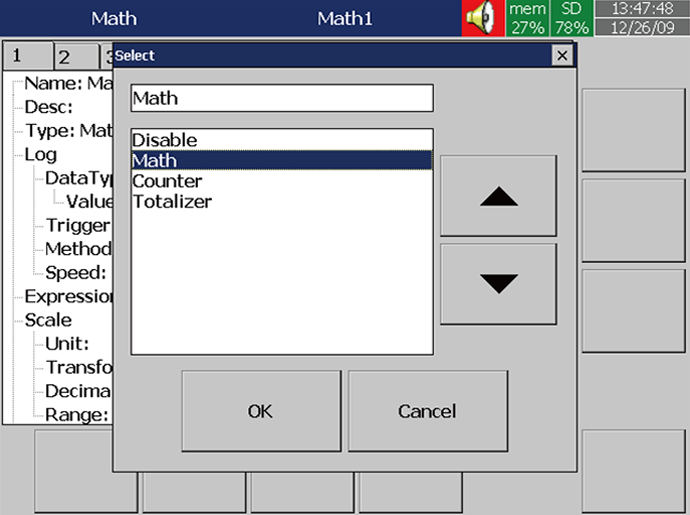

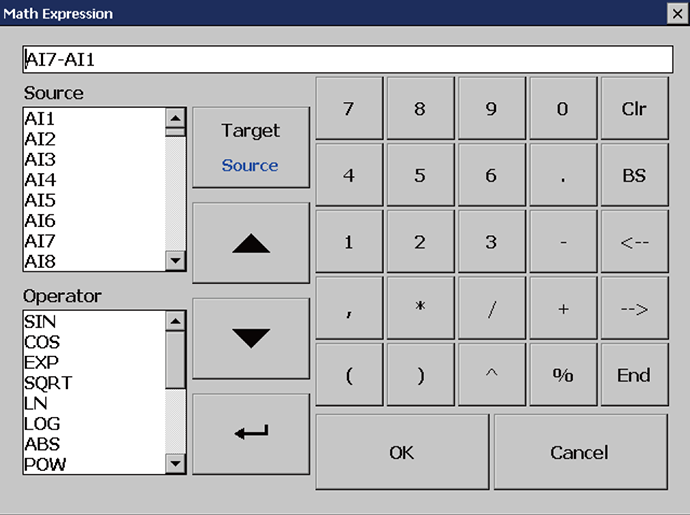

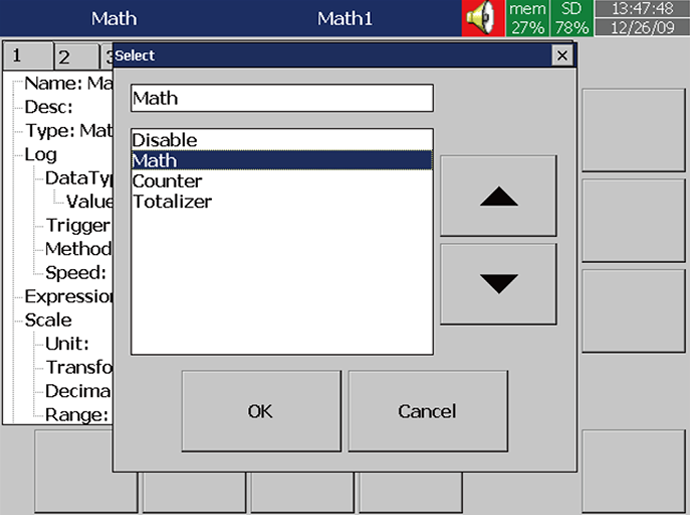

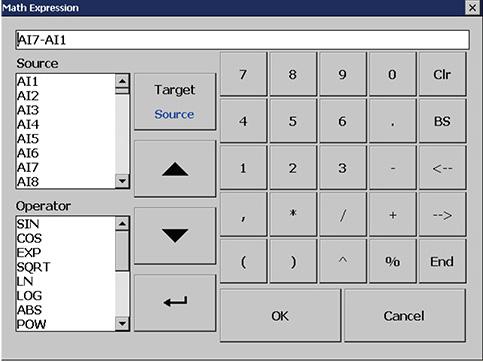

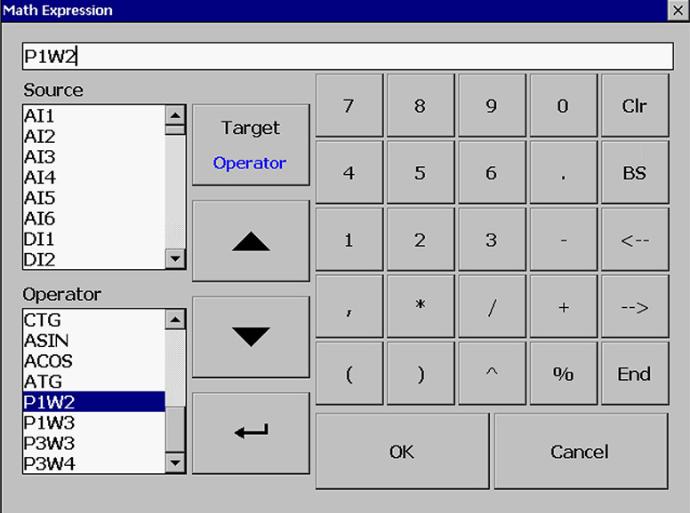

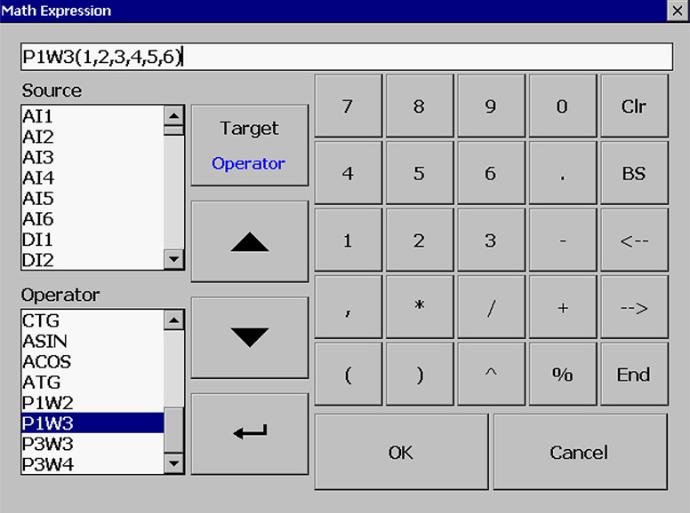

Real-Time Input Math Functions for Signal Logic

Perform addition, subtraction, multiplication, or division between inputs

IA10 enables real-time arithmetic operations between Input 1 (PV1) and Input 2 (PV2), offering a simple yet powerful tool for signal processing and logic comparison. Users can select from four computation modes: addition, subtraction, multiplication, or division, allowing for precise evaluations such as temperature differentials, pressure ratios, or totalized values.

This function is especially valuable in applications involving dual-sensor comparisons, load balancing, or process validation, eliminating the need for external controllers or PLC programming.

Combined with IA10’s dual-input architecture and clear display logic, the built-in math feature delivers fast, hardware-level calculations that enhance system responsiveness and control accuracy.

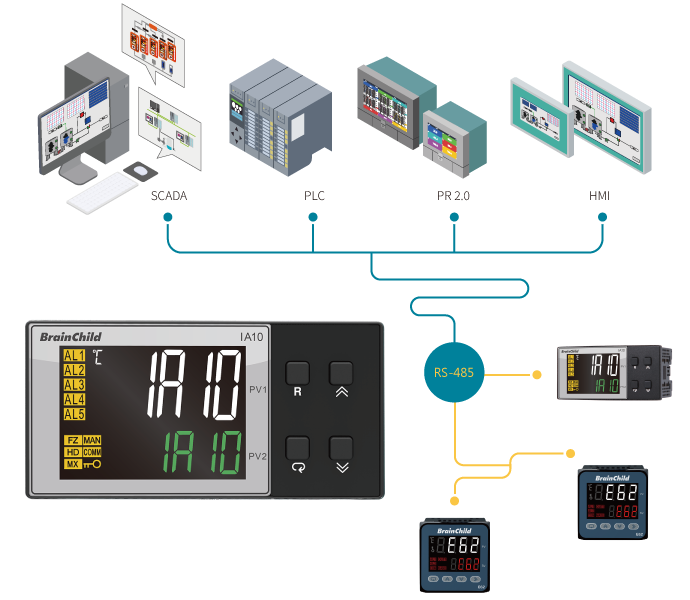

Analog Retransmission and RS485 Modbus Integration

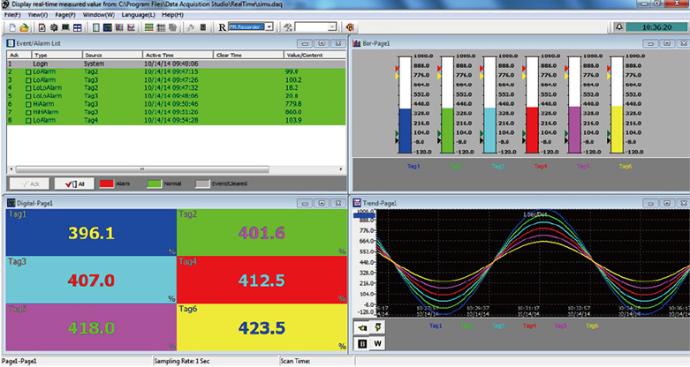

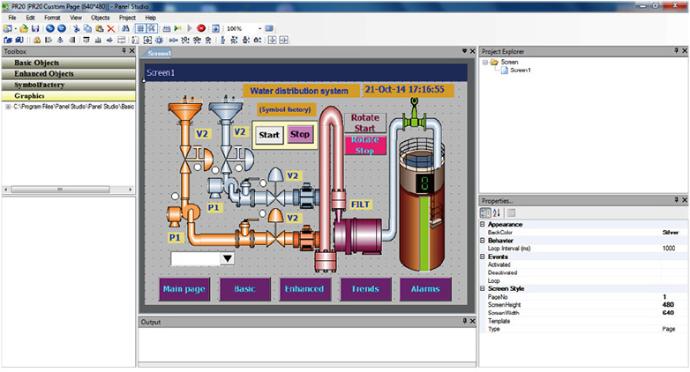

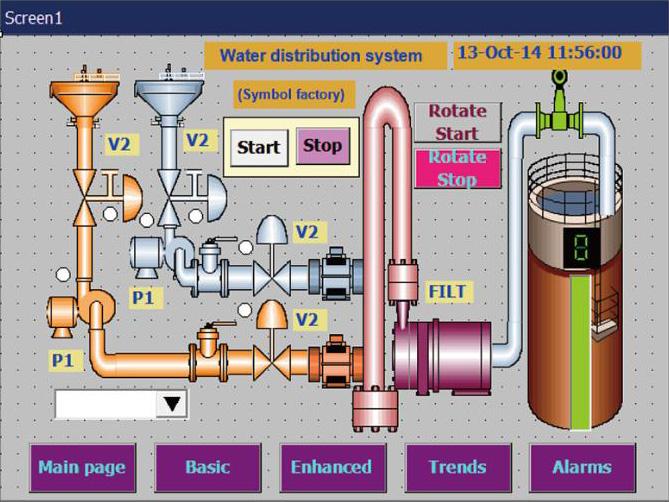

Seamless data connectivity for PLCs, SCADA, and control networks

IA10 offers up to three independent analog retransmission outputs, supporting industry-standard signal formats such as 4–20mA, 0–20mA, 0–10V, 1–5V, and more. Each output can be scaled and adjusted individually using low/high range (ANL/ANH) and zero/span calibration, making it highly adaptable to downstream device requirements.

Users can assign retransmission output values to reflect Input 1 (PV1), Input 2 (PV2), or the result of math operations—enabling real-time data flow to PLCs, chart recorders, and analog-driven actuators. The outputs are electrically isolated for signal integrity and safer wiring.

Complementing the analog interface, IA10 includes a built-in RS485 port with full Modbus RTU slave support. Configuration options include address range (1–247), baud rate (2.4 kbps to 115.2 kbps), data length (7 or 8 bits), parity (even/odd/none), and stop bits (1 or 2). These features ensure smooth integration with SCADA systems, HMI panels, and distributed field controllers.

Together, analog retransmission and Modbus RTU make IA10 a smart data bridge that ensures your sensor readings are accurately and reliably connected to higher-level control platforms—helping improve system visibility, real-time monitoring, and integration cost efficiency.

Applications

Specification

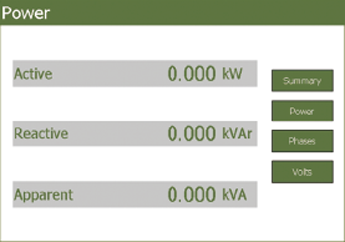

Power

Signal Input 1

Signal Input 2

Event Input

Alarm

Data Communication

User Interface

Programming Port

Digital Filter

Environmental and Physical Specifications

Approval Standards

Download

Visit Download Center to See More Documents & Tools of This Product. Visit

FAQ

IA10 supports thermocouples (J, K, T, E, R, S, etc.), RTDs (PT100 DIN/JIS), and analog signals including 4–20mA, 0–10V, and mV input. Dual-channel input enables flexible sensor integration and signal comparison.

Yes, IA10 features RS485 communication with Modbus RTU protocol, allowing easy integration with PLCs, SCADA, HMI, or distributed control systems for real-time data monitoring.

IA10 supports up to three analog retransmission outputs, including 4–20mA, 0–10V, and 1–5V. Each output can be independently scaled to match downstream device requirements.

IA10 supports five independent alarms, each with its own Form A relay output. Alarm modes include high, low, and latch types, and can be customized per application.

IA10 is ideal for temperature and pressure monitoring, dual-zone control, sensor validation, and alarm-based safety logic, widely used in automation, food processing, and equipment integration.

Brochure_IA10_EN

Brochure_IA10_EN

Software_USB Update Tool_V3.1

Software_USB Update Tool_V3.1