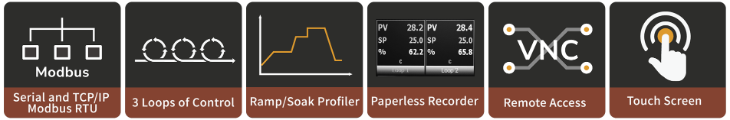

Features

- 4.3" touchscreen with smart icon-based interface

- Supports up to 3 independent PID control loops

- Offers fixed, profile, and cascade control modes

- 64-segment profile control with event triggers

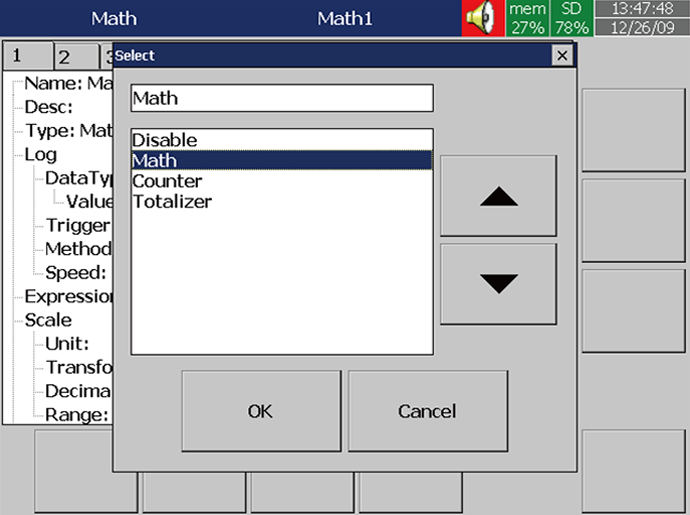

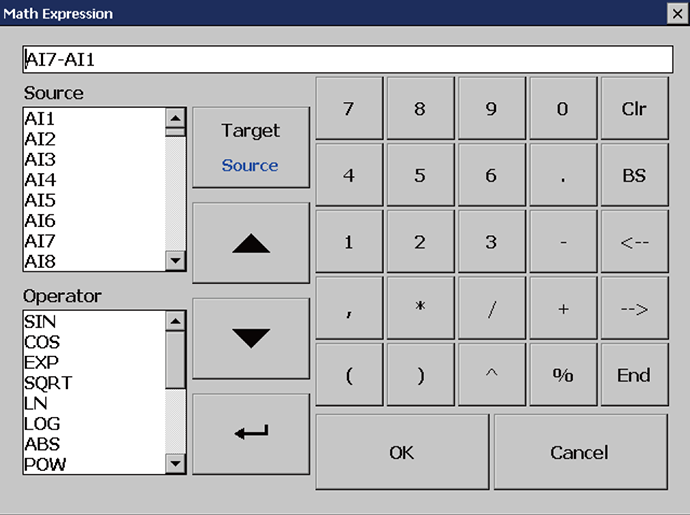

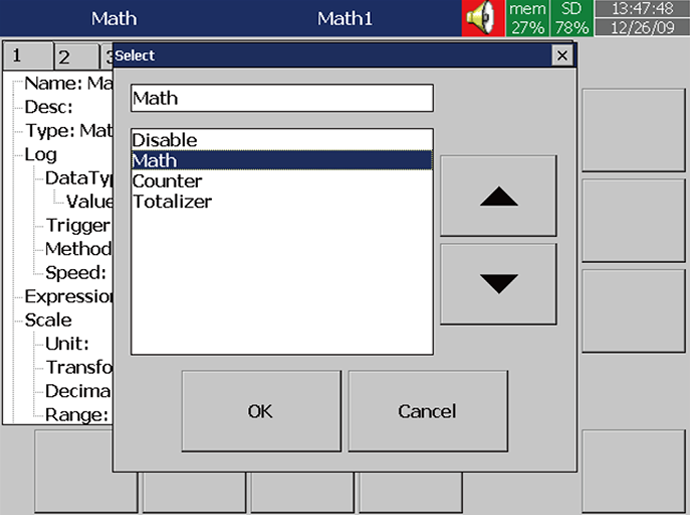

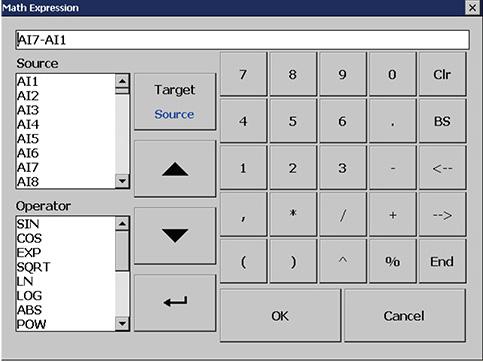

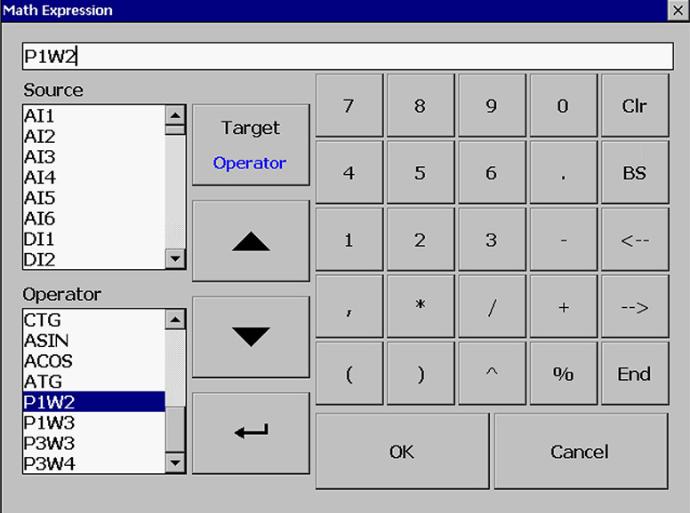

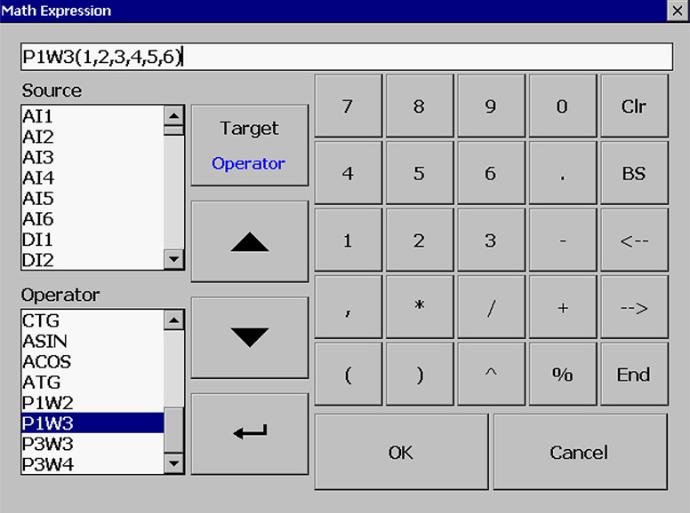

- Built-in math, logic, and timer (up to 20 sets)

- Provides up to 19 alarms with relay/soft options

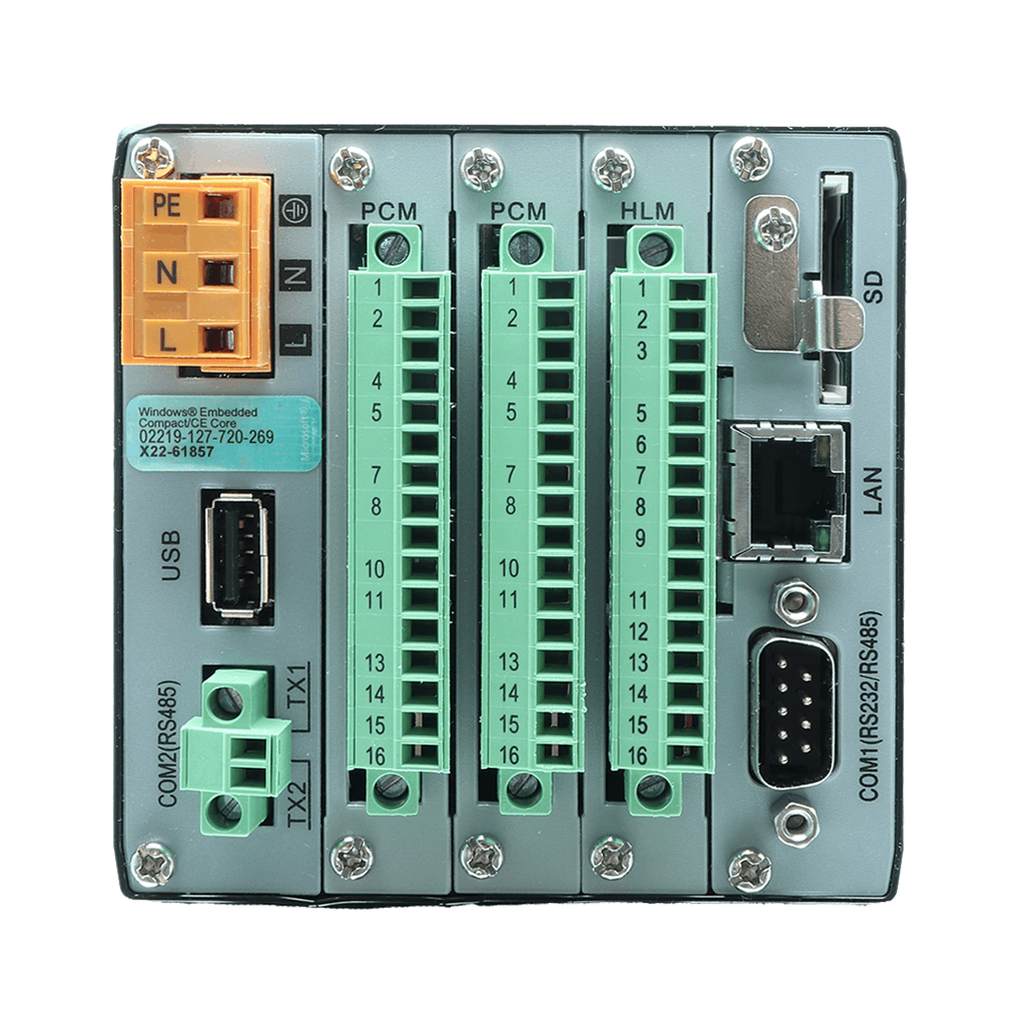

- USB and SD card slots for data export and backup

- SD card logging with up to 1-year data retention

- 4 user groups with up to 30 password-protected users

- Audit trail complies with 21 CFR Part 11 standard

- Meets AMS 2750F for thermal process control

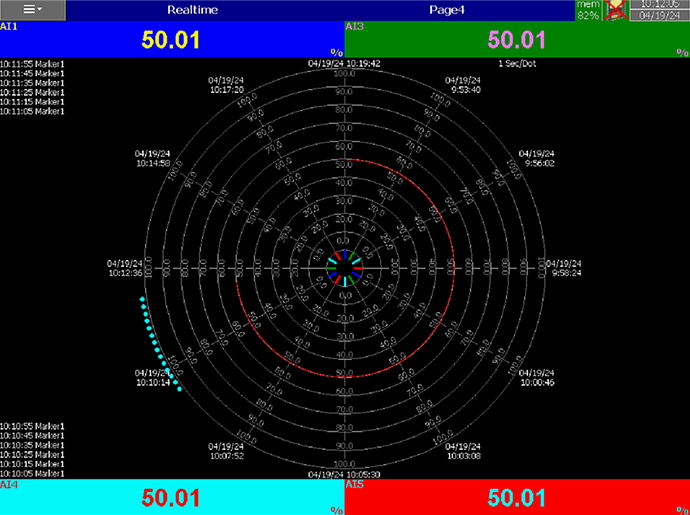

- Real-time trend chart and event log display

- Auto program recovery after power interruption

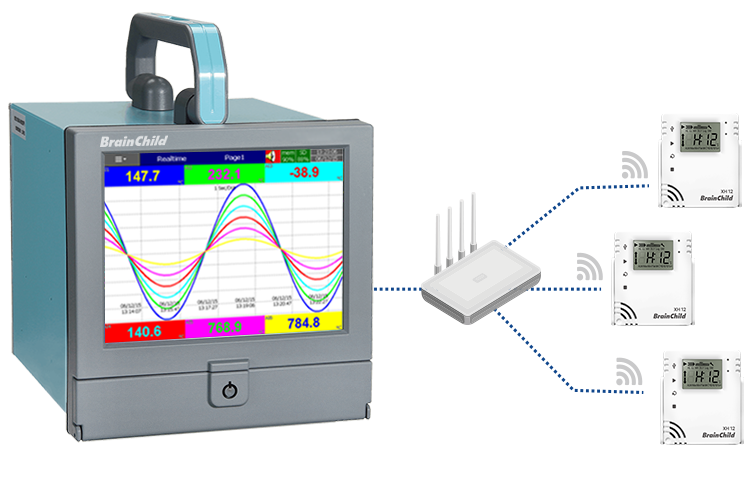

- Supports Modbus TCP/RTU, RS-232/485, Ethernet

- Expandable I/O via PCM and HLM control modules

- Supports TC, RTD, mA, and voltage input types

- Multi-language UI with up to 11 language options

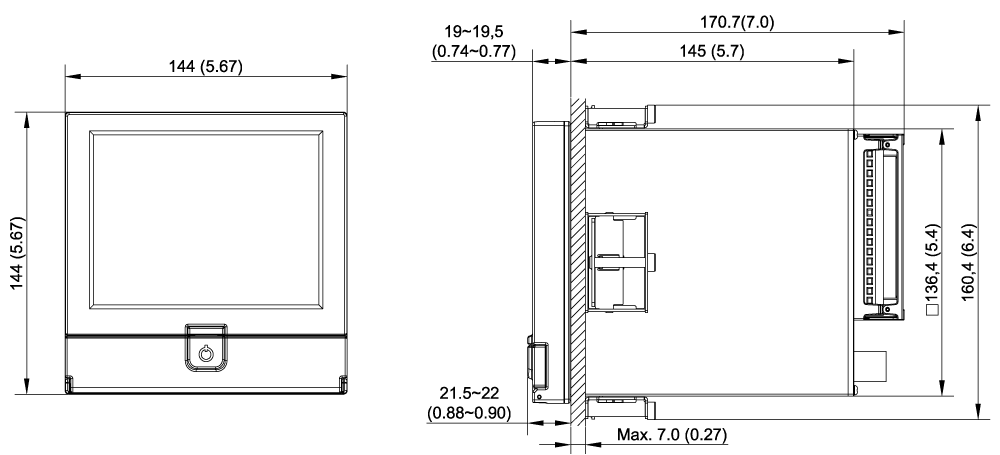

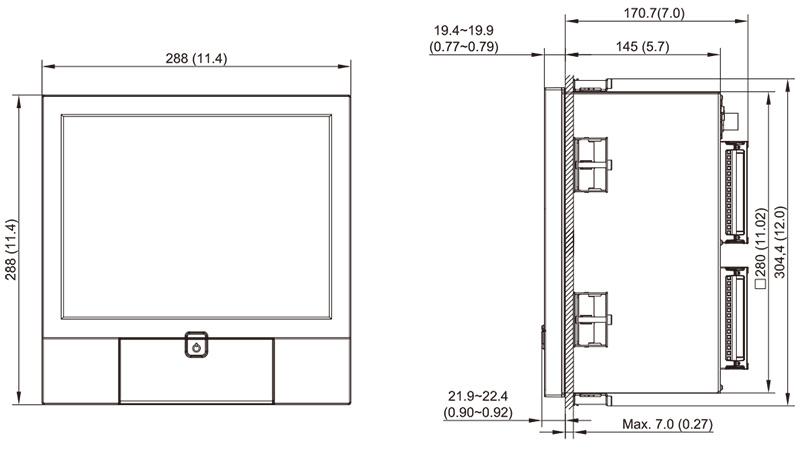

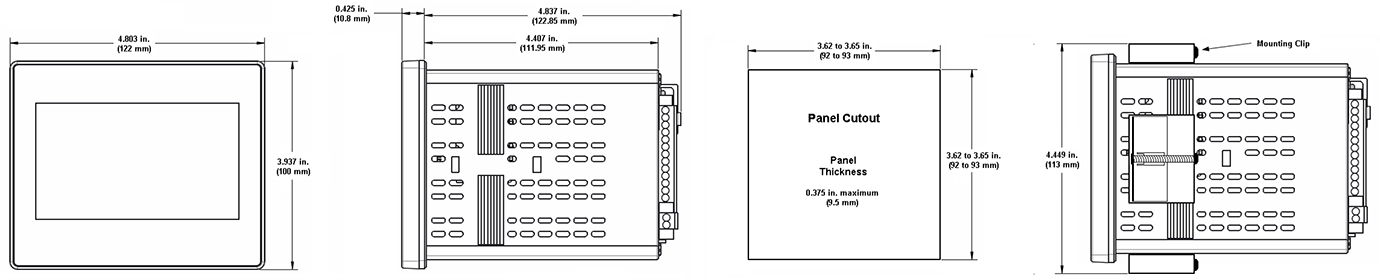

- Panel-mount DIN design for compact installations

MCT - 1/4 DIN Controller

All the functionality of multiple devices in

an easy to use low cost controller

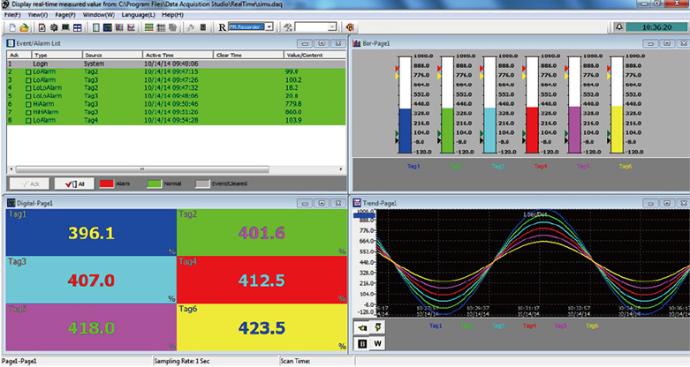

The MCT system combines multiple control and monitor components in a single device. The 4.3” color touch

screen allows users to select PC type menu or smart device slide-nav icon navigation to match familiar personal

preferences for operation. Secure email (SSL/TLS), SMS (text messaging), FTP, FileWeb and DataWeb protocols

allow the MCT to interface and backup data to LAN/WAN based systems and data bases, eliminating the need for

additional data acquisition equipment. Math/Logic/Timer functions included as standard to reduce additional

system components.

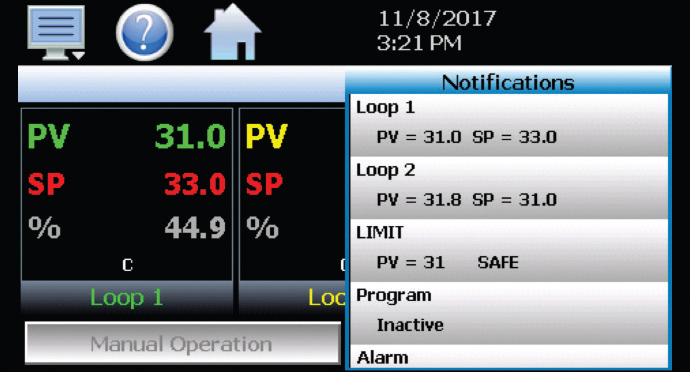

The MCT is equipped with a Web server and remote control via VNC from any smart device (smartphone/tablet/

PC, etc.). Single touch notification provides loop, alarm, profile and system information in a simple touch scroll

list from any screen location. All software functions are standard, no options to pay extra for!

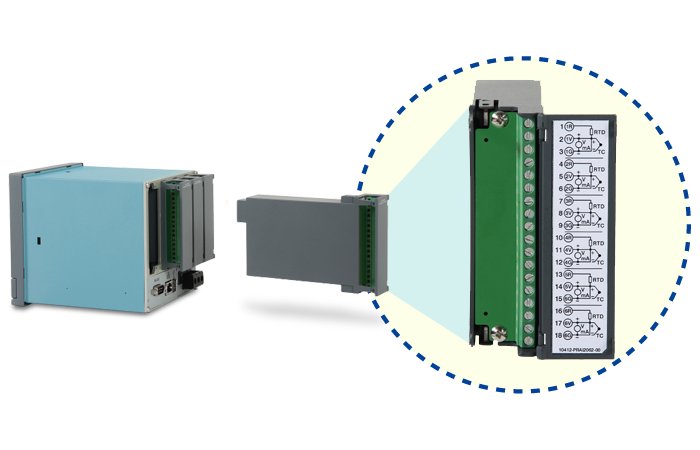

Loop Overview|Modular Multi-Loop Design

Supports up to 3 PCM cards and 1 FM-approved HLM

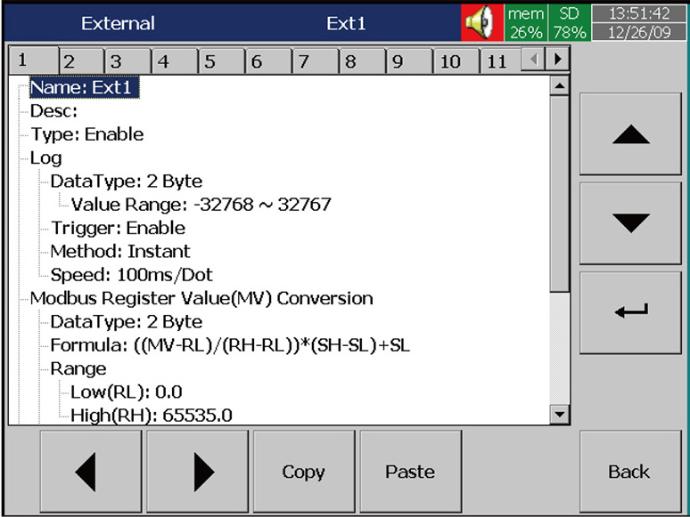

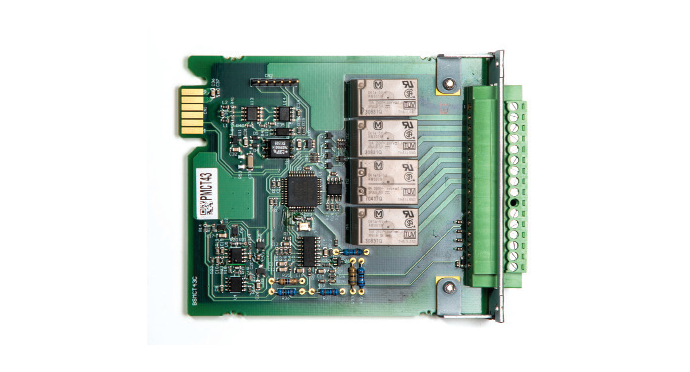

The MCT multi-loop controller features a three-slot modular architecture, allowing flexible installation of up to three PCM (Programmable Control Modules) to independently manage static, program, or cascade control modes per loop.

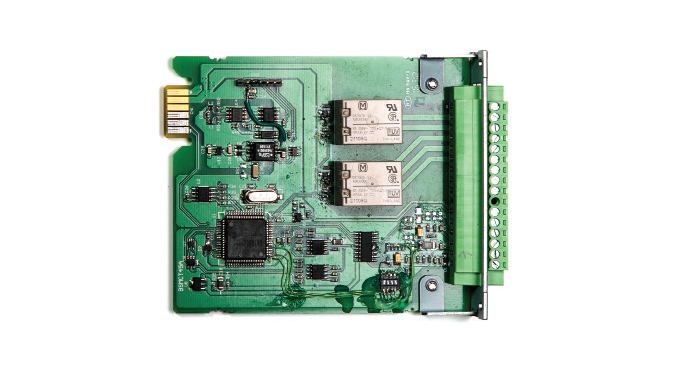

In addition, the MCT supports the installation of one HLM (Hi-Limit Module) — an FM-approved safety module for over-temperature protection. The HLM must always be installed in the last available slot of the configuration. For example, in a setup with 1 PCM + 1 HLM, the HLM must be in slot 2; with 2 PCMs + 1 HLM, it must be placed in slot 3.

Powered by a multi-processor design, the MCT delivers zero-latency screen updates and control response, enabling precise and responsive operation even in demanding applications.

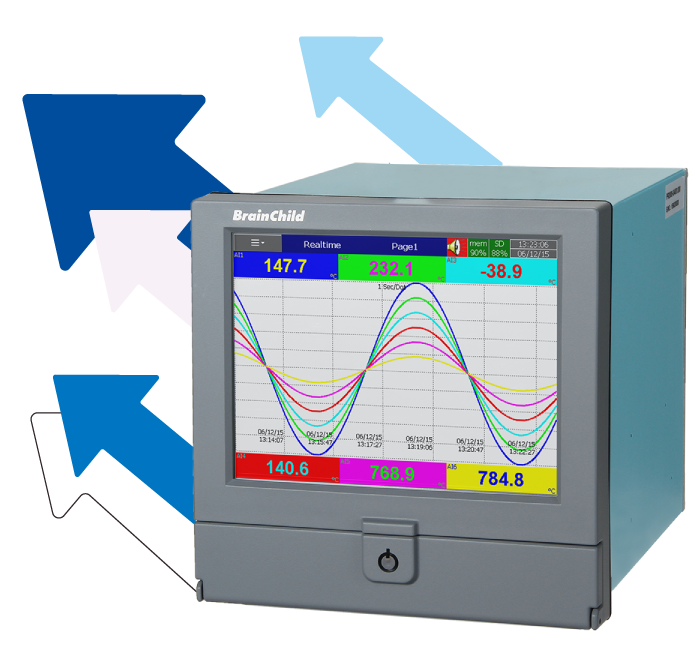

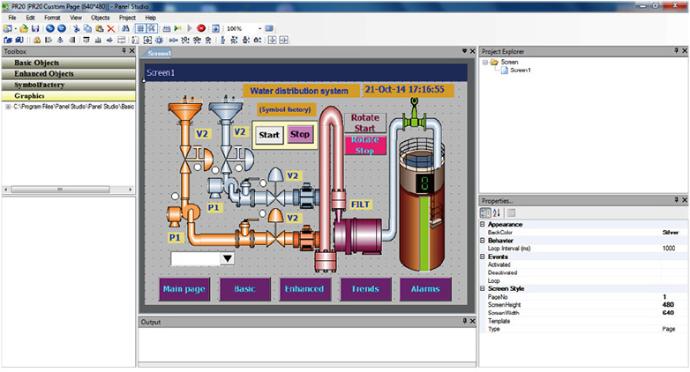

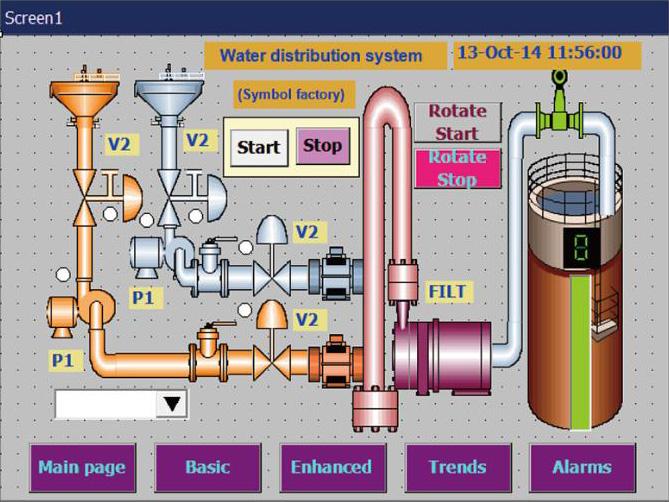

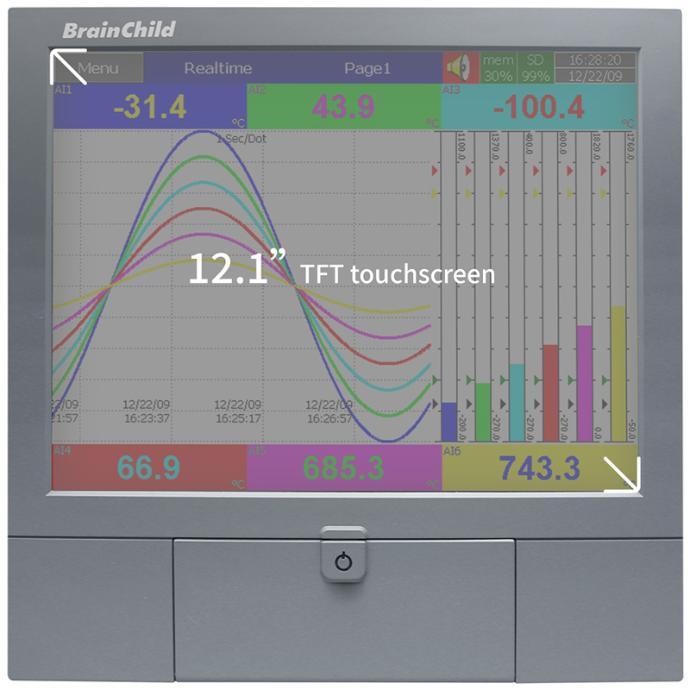

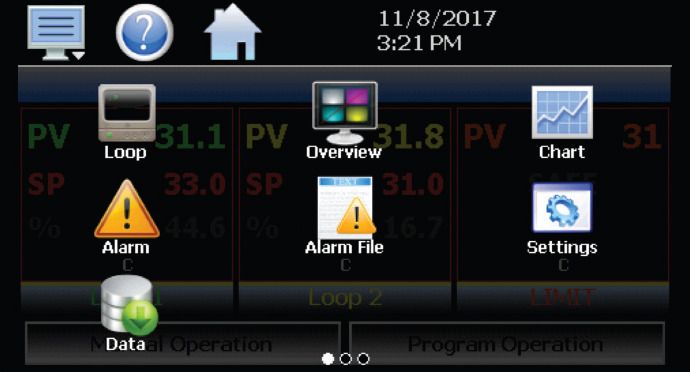

Touchscreen UI | 4.3" Smart Navigation Display

Intuitive HMI with app-style navigation and instant access

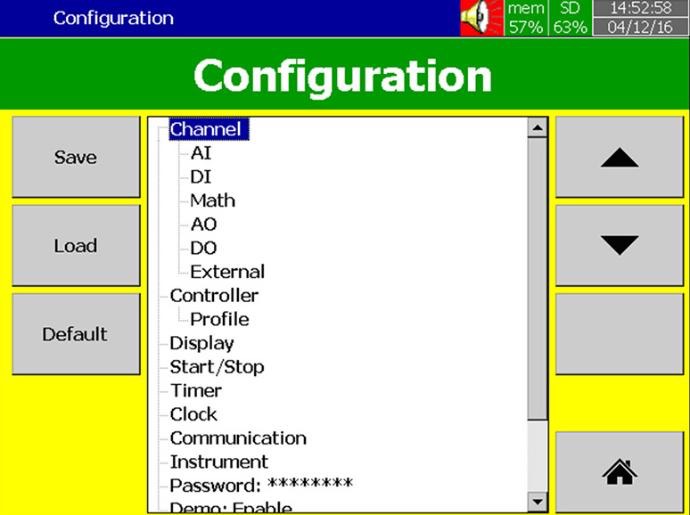

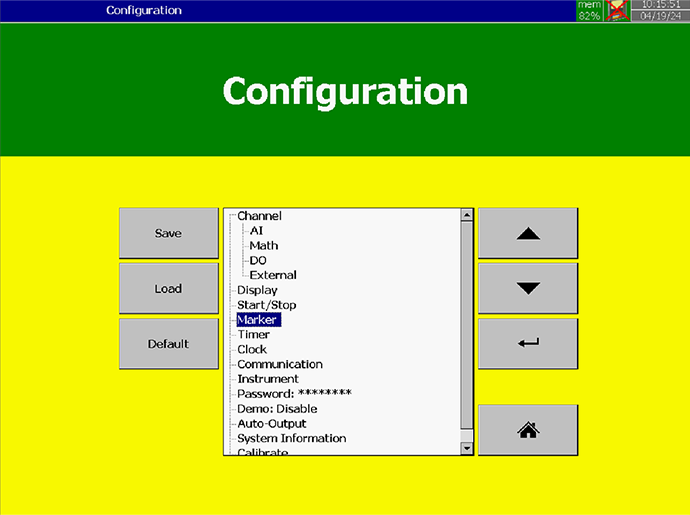

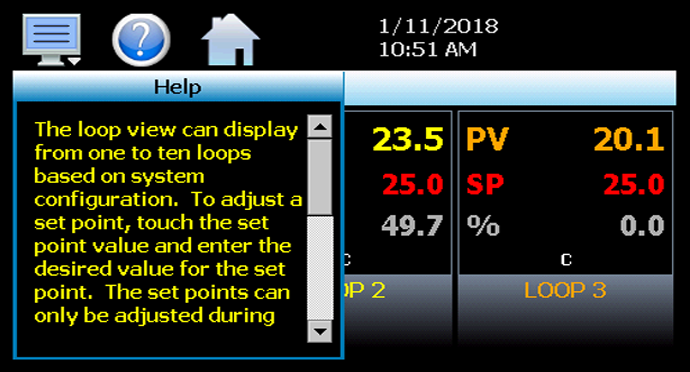

The MCT multi-loop controller is equipped with a 4.3-inch color touch screen that delivers an app-like user experience similar to modern smartphones and tablets. Users can effortlessly navigate through menus and settings via touch gestures, slide menus, and scrollable lists, providing seamless access to all control functions.

Each screen functions like a dedicated "app", making it easy to manage setpoints, alarm settings, trend charts, and system configuration with just a few taps. The interface features a standardized toolbar across all screens, offering quick access to home, help, notifications, alarms, and system menus at any time.

With its icon-based smart UI and real-time data visibility, the MCT ensures a highly intuitive and efficient user experience, reducing training time and improving operation speed in industrial environments.

Menu Navigation

Icon/Page Navigation

Notification/Touch Lists

Content Sensitive Help on every view

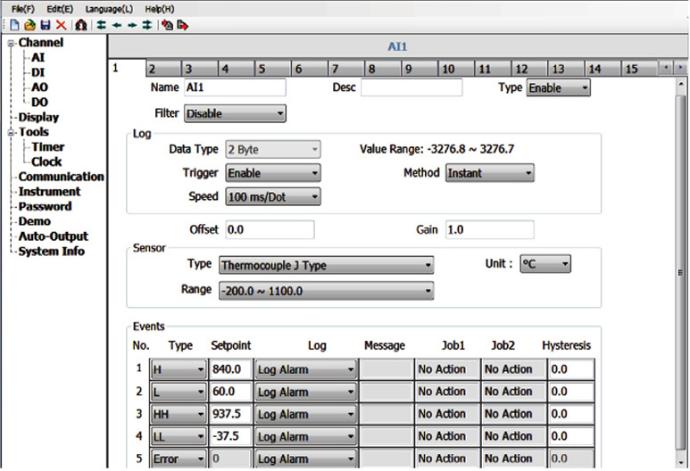

Loop Control | PCM with Fuzzy & PID Logic

Up to 3 loops with 4 outputs each and real-time response

Each Process Control Module (PCM) in the MCT supports one independent control loop, and up to three PCM modules can be installed for a total of three loops. Each module includes four assignable output channels, supporting diverse process needs such as heating, cooling, or alarm triggering.

Control logic includes static setpoint, profile (programmed curve), and cascade control modes. Every PCM uses adaptive fuzzy logic combined with PID algorithms, with up to five PID parameter sets per loop for optimized dynamic control.

With its multi-processor design, the MCT ensures instantaneous feedback and screen responsiveness, delivering high-speed, stable process management across all loops.

FM-Approved Limit Module | Safety Built-In

High/low limit safety and alarm logic with dual output

The HLM (High Limit Module) for the MCT controller is a FM-approved safety solution designed to provide high, low, or high/low temperature limit control. It can be installed in slot 2 or slot 3 of the MCT's modular backplane.

Each HLM module includes two independent alarm outputs, allowing users to configure flexible alarm logic tailored to specific process safety requirements. With HLM integration, the MCT offers both PID process control and limit safety control in one platform—eliminating the need for external safety relays or limit controllers.

This integrated approach helps reduce hardware costs, installation complexity, and panel space consumption, making it ideal for regulated applications in thermal processing, laboratory ovens, or heat treatment systems.

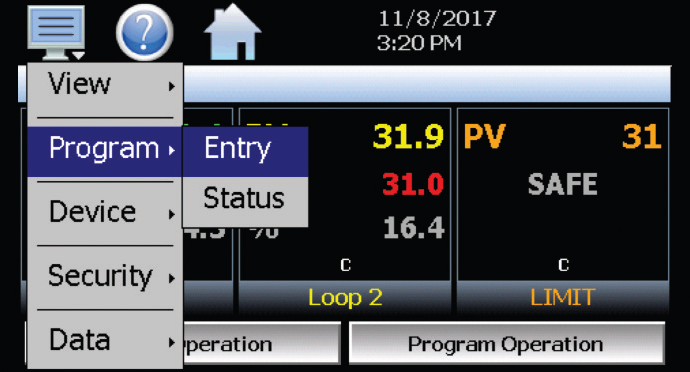

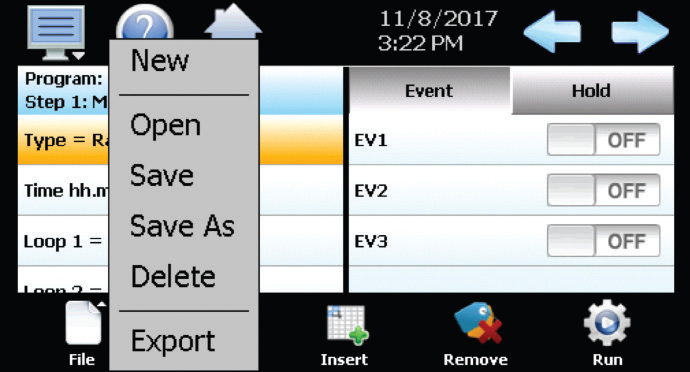

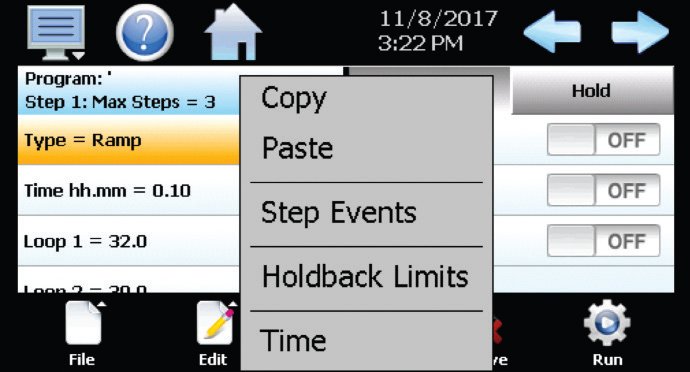

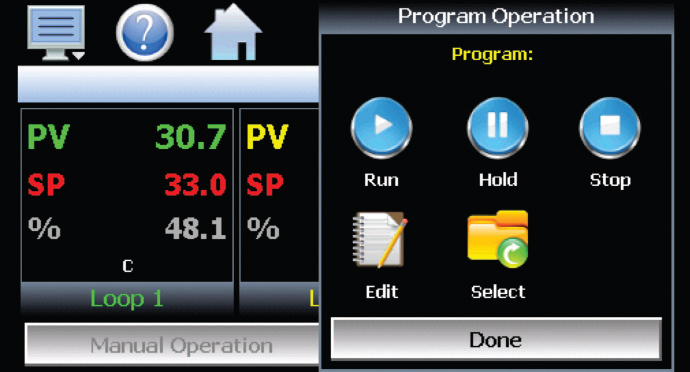

“ONE TOUCH” Profile Program Entry

PROGRAM ENTRY IS QUICK AND EASY

The MCT provides program entry operations on a single screen.

Touch scroll lists and menu icons provide dynamic operations based on user selections. Simple on/off buttons within the scroll lists eliminates navigating through multiple screens to complete program entry tasks.

64 programmable steps include ramp, soak, jump and jump cycles. Loop setpoints, step events, step hold/wait for and repeat functions provide advanced program functionality with unlimited program storage (limited only by 8GB of memory).

Copy and paste functions allow quick entry of step data as well as copying step events to all remaining program steps to reduce complex program tasks.

Slide out numeric keypads and program control windows allow the user to maintain view of the background window to reduce screen clutter. Transparent dialogs and pop-up menus provide quick operations for all profile functions without leaving the main profile entry screen.

Profile run status is available in detail or from loop and overview screens as well as notification drop down touch lists which are available on all of the MCT runtime screens.

The help icon in the command bar provides context sensitive infromation for all views including Profile Program Entry.

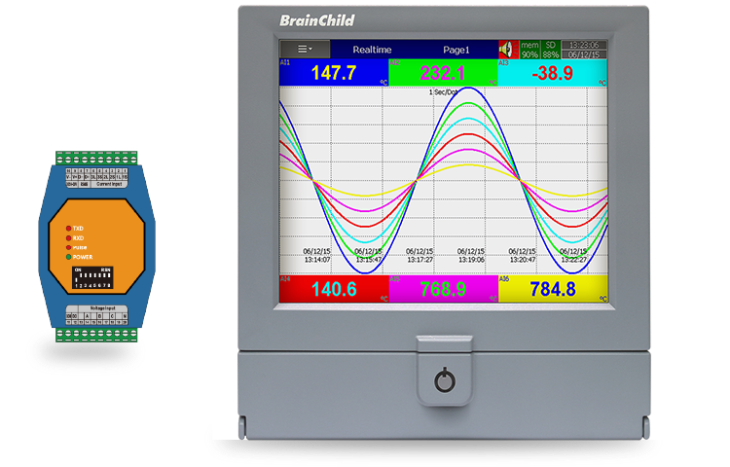

Remote Control/Monitor from PC/SmartPhone/Tablet

MCT includes a remote VNC server for remote monitor or control and a monitor only web server from any smart device anywhere, anytime.

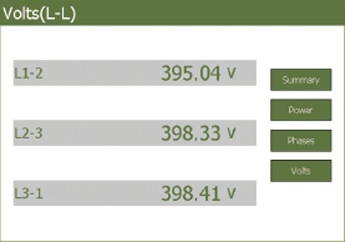

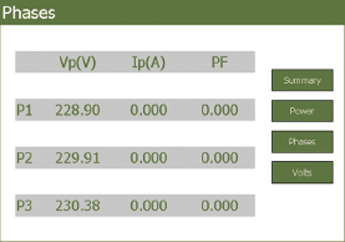

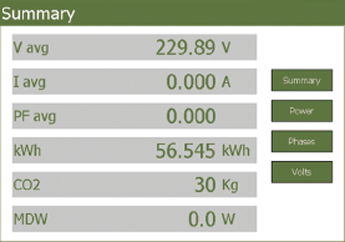

Data Logging

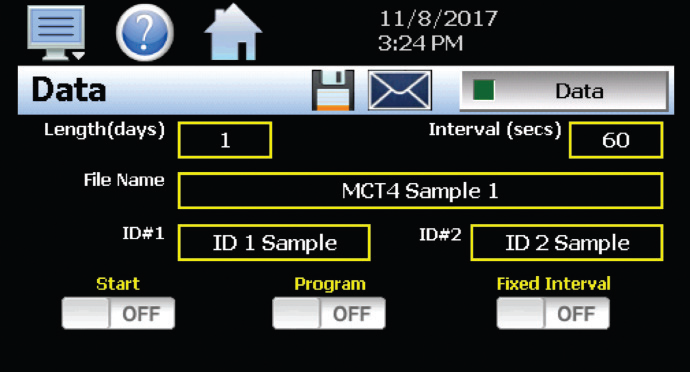

The MCT supports data logging of all process variables with 8GB of storage standard. Filename, lot number, batch number, log interval and days to log are all configurable from the front touch screen. Program log control allows the user to start/stop logging using the automated programmer with the program name used as the datalog name. “Always Logging” startup option provides the ability to enable the MCT to log at all times to maintain 24/7 logging operation. The “Days To Log” option allows the user set the time in days before a new file is started to sync data files to match product cycles as well as keeping data file size manageable.

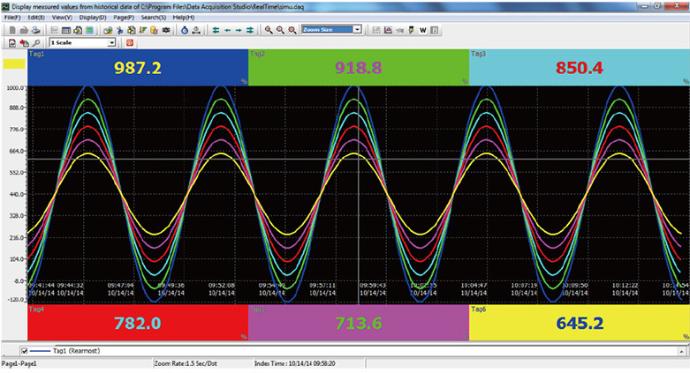

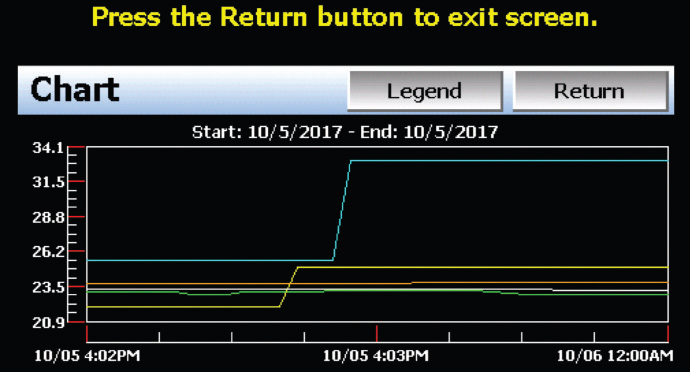

Historical Data Viewer

MCT includes a historical data viewer that allows trend chart viewing of data files stored on the device (8GB max). Selection of data points, data start/end time along with drag and zoom trend options (with legends) provide a quick and easy view of any batch run for any date and time.

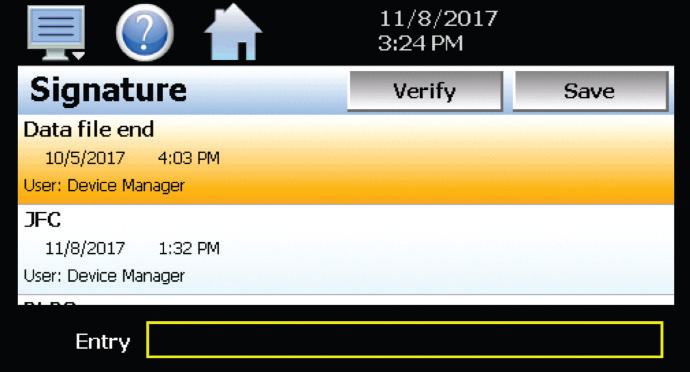

Digital Signatures

MCT data files and audit trails are digitally signed to maintain data integrity and meet regulatory requirements for digital (vs. paper) operation. This is different from data file encryption since the digital signature protects the file from being altered in any way. Additional signatures (unlimited) can be added by authorized users along with text to describe the signature (i.e. batch passed, setpoint change, etc.). Meets the requirements for data acquisition for CFR21 Part 11 and AMS 2750F

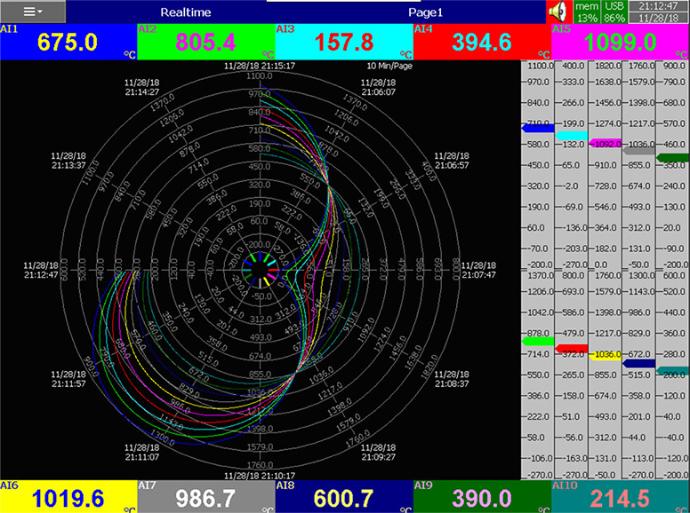

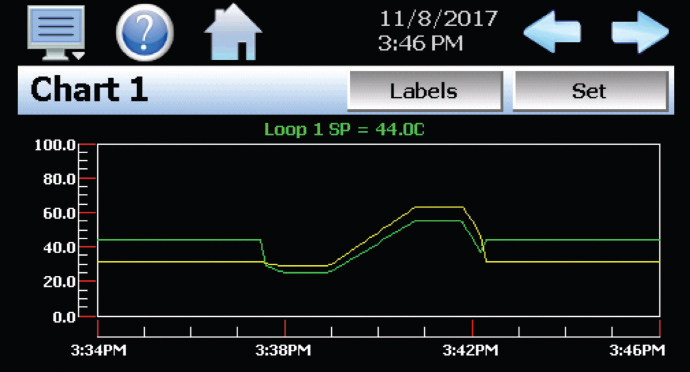

Chart Trend View

Four real time charts configurable to display any variable in the controller (up to 6 values per view) over a selectable time period of 4-minutes to 24 hours. With configurable left and right axis, automatic or defined chart scales and finger pinch on the fly zoom, the 4 configurable charts allow an operator a 1-button touch to view recent process history without opening a data log file.

File Management

LAN/WAN PROTOCOLS

MCT includes FTP (File Transfer Protocol) and FileWeb transfer (https:// encrypted communications) of all file data from the controller. DataWeb protocols allow the MCT to transfer real time/historical process informaton to secure data bases via LAN, WAN based manufacturing systems using standard SQL (Structured Query Language) data interfaces . This eliminates the need for additional data acquisition or network hardware.

USB/LAN BACKUP AND CONFIGURATION

File transfer utilities allow export of all data to a standard USB memory device, LAN storage. Internal memory can be cleared after export to provide “maintenance free” storage operation.

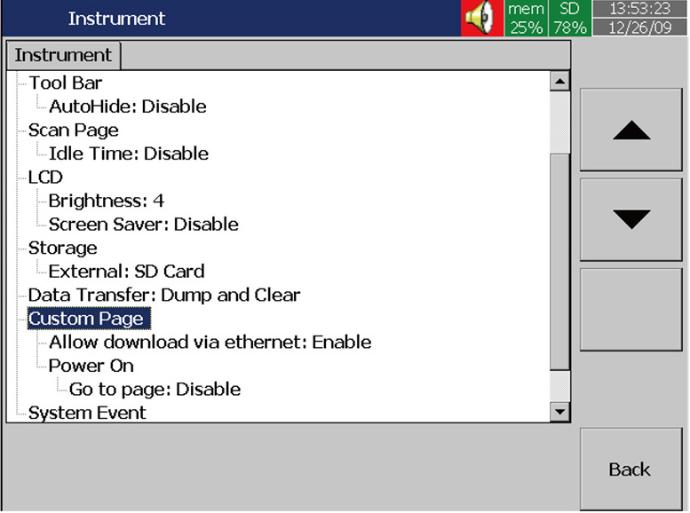

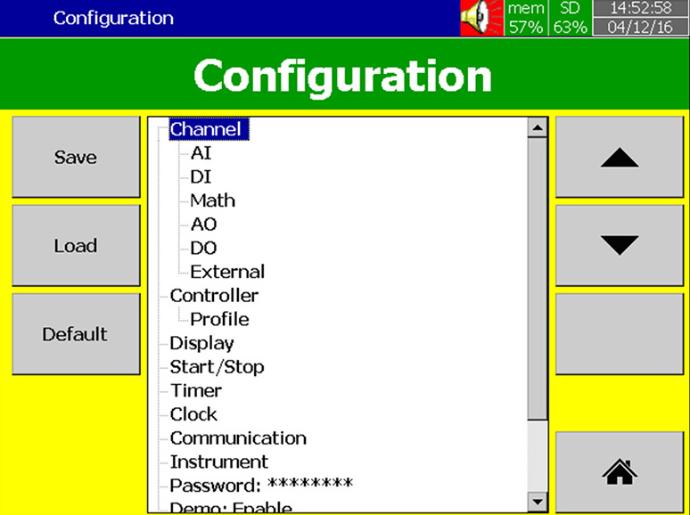

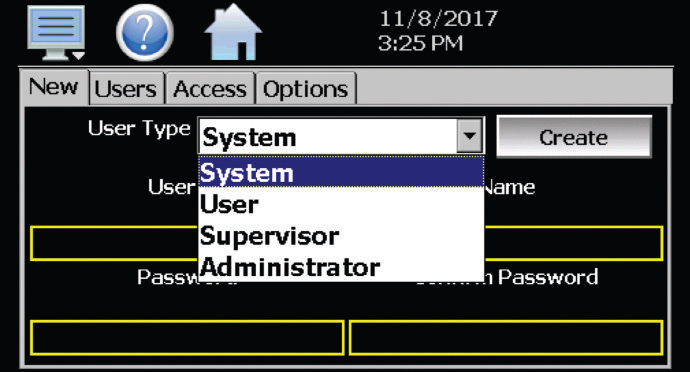

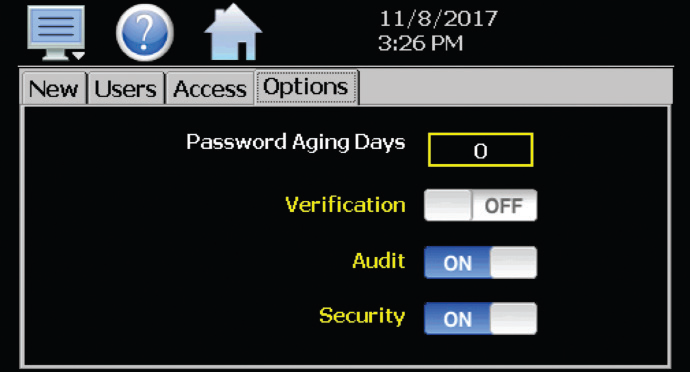

User-Based Security

MCT includes an easy to configure, full user based/ user rights security for system, user, supervisor and administrative levels. Up to 30 users supported with each user having the option of type assignment (user, supervisor, etc.). Each function in the MCT can be enabled or disabled for each user type. The user decides which options each user type has access to rather than a “number” based system which can include functions not desired for most“process secure” operations.

Password Aging and Verification

Password aging, auto log off and user re-verification provides the flexibility and security required for regulated processes.

Audit Trail Entries

MCT includes full audit trail entries for all user activity. Any process change must pass the security check and is written to the audit trail. Audit trail includes date, time, user name and user action. (example: Loop1 setpoint change from 21.0 to 23).

11 Languages Supported For Global Usage

MCT provides instant selection of 11 languages providing global usage for shipment anywhere in the world (no reboot or special order codes required). Chinese Simplified, Chinese Traditional, English, French, German, Italian, Japanese, Korean, Portuguese, Russian and Spanish supported with a single touch.

Applications

Specification

Base Specifications

Input Specifications

Output Specifications

Control Function (PCM)

Download

Visit Download Center to See More Documents & Tools of This Product. Visit

FAQ

The MCT supports up to 3 independent control loops, each handled by one PCM module.

Yes. By installing an HLM (Hi-Limit Module) in slot 2 or 3, MCT provides FM-approved high/low limit control with dual alarm outputs.

The MCT supports Modbus RTU, Modbus TCP, RS-232/485, and Ethernet. USB and SD card ports are also available for data backup.

Yes. The MCT supports audit trail logging, user access levels, and profile control, meeting key requirements of AMS 2750E and CFR 21 Part 11 for thermal process validation and traceability.

The MCT features a 4.3” color touch screen with app-like navigation and multi-language UI, making it intuitive to operate for most users, even with minimal training.

Brochure_MCT_EN

Brochure_MCT_EN