Features

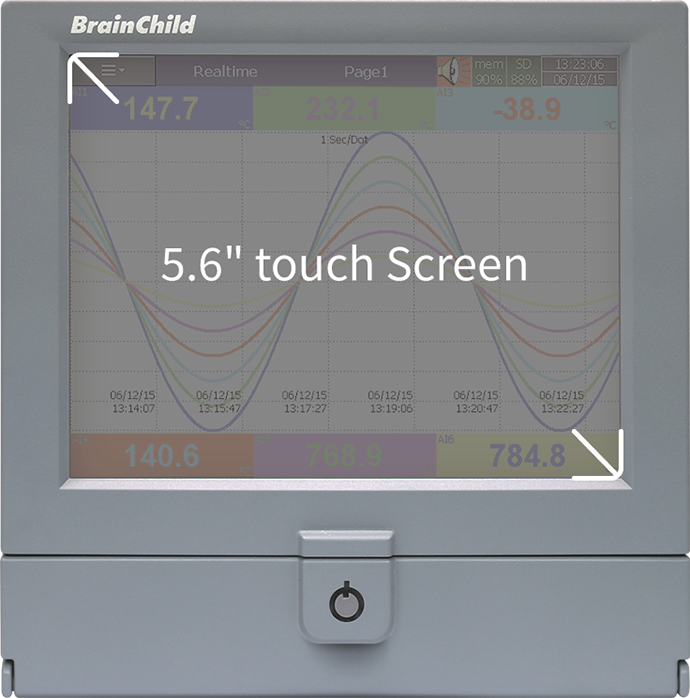

- 5.6" TFT Color LCD Touchscreen with smart UI

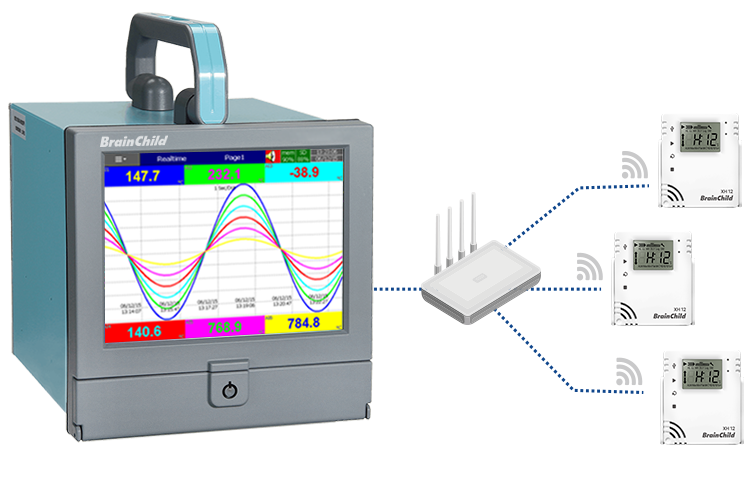

- Wi-Fi support for wireless Temp & RH logging

- New EMS interface for real-time power tracking

- AMS2750H compliance with AI306 analog module

- FDA 21 CFR Part 11 compliance for secure records

- Batch recording with digital file management

- Customizable display layouts for clear visualization

- Multi-format data export: PDF, Excel, CSV

- Ethernet connectivity for remote data monitoring

- High-capacity SD card for extended logging

- Enhanced high-accuracy analog input/output

- Advanced alarm functions with high/low limit alerts

- Configurable logging intervals from 1s to 24 hrs

- Automatic data backup during power interruptions

- Password protection for secure system access

The All-New PR 2.0

Smarter, Smoother, Stronger

Redesigned for smarter, faster operation

BrainChild proudly presents the PR 2.0 firmware, marking the most significant upgrade in the history of the PR paperless recorder series. This version introduces major enhancements across the board, including AI306 high-accuracy analog input for AMS2750H compliance, support for the Energy Management System (EMS), Wi-Fi data logger connectivity, customizable display interfaces, FDA 21 CFR Part 11 compliance, batch recording, and improved visual operations — all designed to optimize industrial monitoring with greater efficiency and flexibility.

PR 2.0

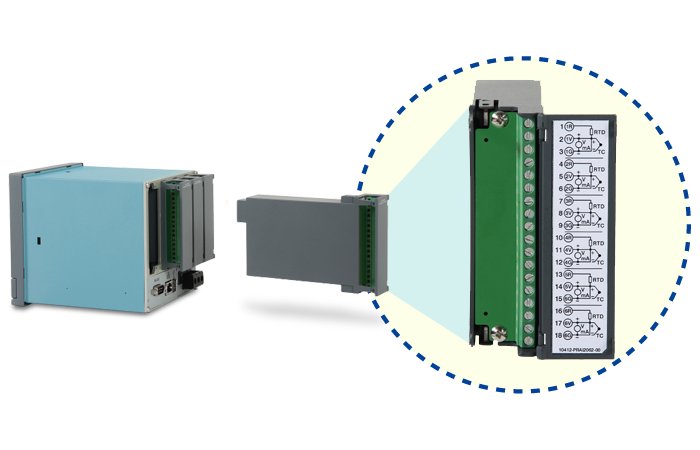

Supports AI306_6 High-Precision Input Module

Boosts accuracy and meets AMS2750H standards

PR 2.0 now supports the new AI306_6 six-channel high-precision analog input module, improving measurement accuracy from ±1.0°C to ±0.6°C. This enhanced precision meets the AMS2750H requirements for Field Test Instruments in aerospace heat treatment, making it ideal for temperature uniformity surveys and demanding thermal processes.

PR 2.0

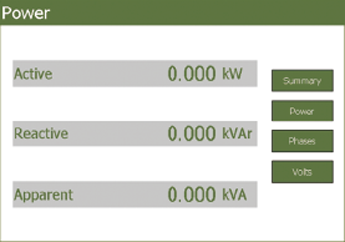

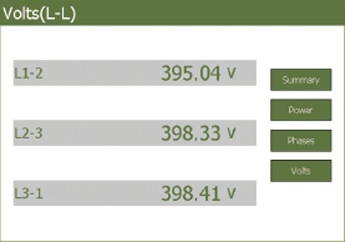

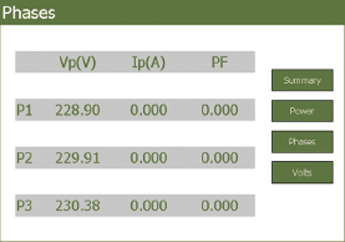

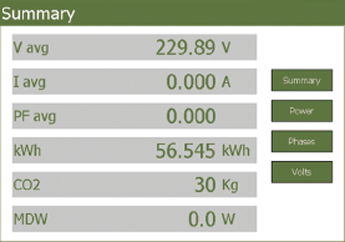

New Interface for Energy Management System

Real-time power metrics and energy efficiency insights

PR 2.0 introduces a new EMS interface, enabling advanced and flexible power monitoring. By connecting to compatible external power transducers via RS485, the system captures voltage and current signals, then uses built-in math functions to calculate and display real-time power, electricity usage, and energy performance metrics(external power transducer required)*. This upgraded design not only supports comprehensive energy analysis but also delivers actionable insights for smarter industrial decision-making.

*The EMS function requires an external power transducer to operate. For more details, please contact our sales team.

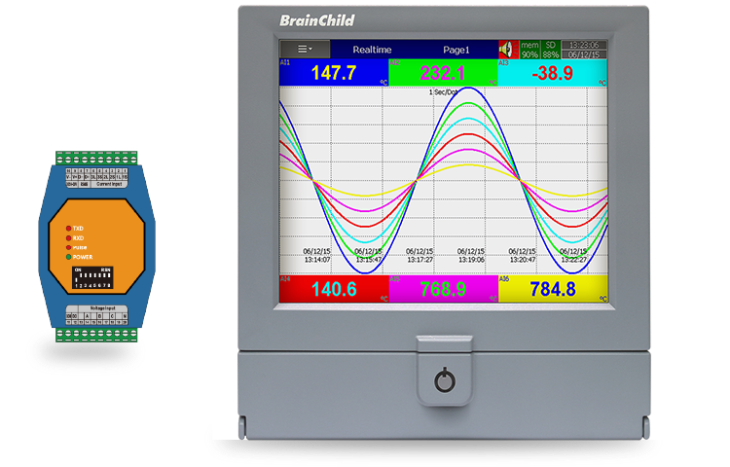

PR 2.0

Wireless Integration with XH12 Data Logger

Monitor temperature wirelessly across zones and facilities

PR 2.0 seamlessly integrates with BrainChild’s XH12 wireless temperature data logger. By connecting to a wireless router via the built-in Ethernet interface, the system receives Wi-Fi signals from all XH12 units, enabling real-time temperature monitoring across storage areas, production lines, and other key zones.

The XH12 features automatic data retransmission, ensuring that even during temporary disconnections, all data is safely recovered and transmitted once communication is restored. This makes it especially ideal for cold chain storage monitoring, or when used alongside the EMS module to evaluate HVAC energy consumption and system performance.

This upgrade not only benefits new installations but also supports legacy users. Version numbers now follow the 2.xx format and are fully compatible with all PR devices manufactured after 2018. Existing units can be easily updated via USB or SD card, unlocking all new functions with a simple process — maximizing device value and return on investment.

The PR series is more than a data recorder—

it's the foundation for smarter process management

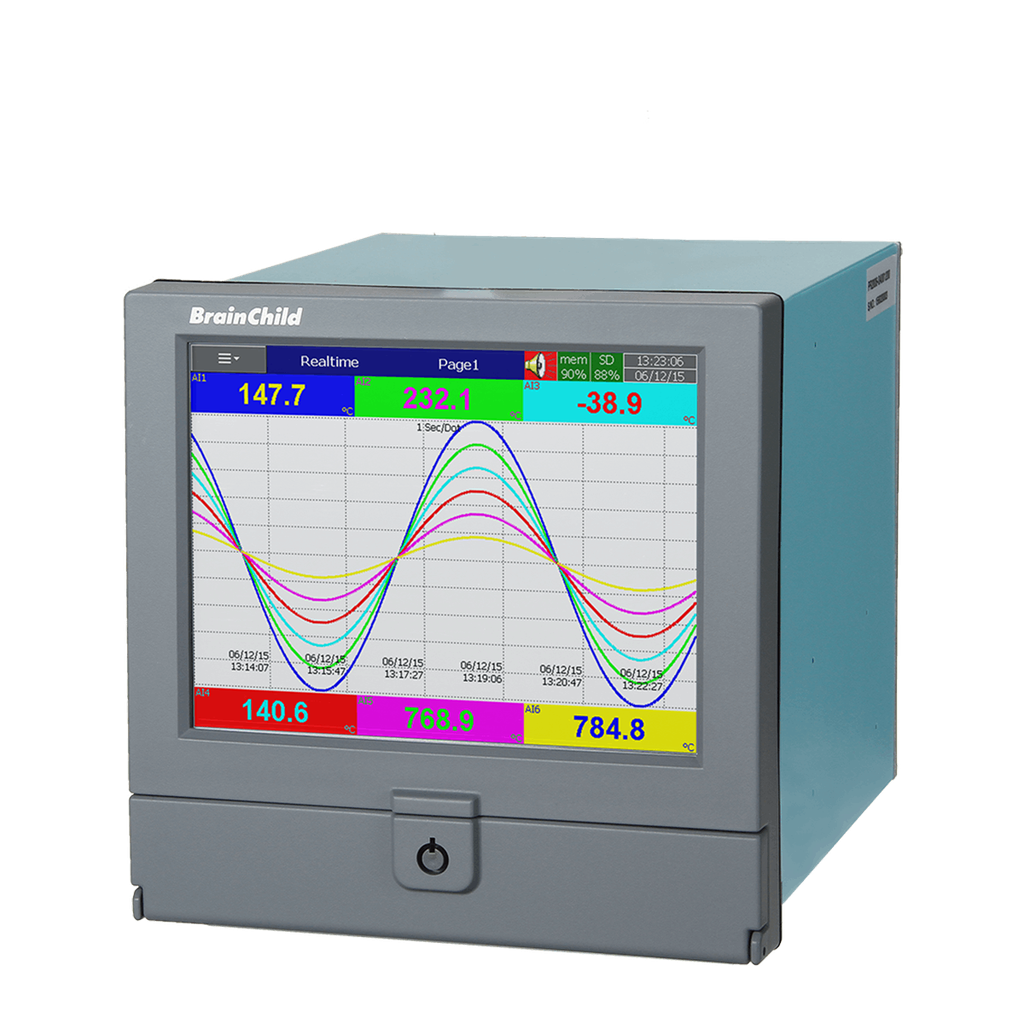

As an industrial-grade paperless recorder, the PR series combines advanced monitoring capabilities with all the essential core functions required for modern manufacturing environments. Whether it’s long-term, stable process data recording, high-precision multi-channel input, or an intuitive graphical user interface, the PR series delivers comprehensive support to help users monitor operations in real time and ensure cnsistent product quality.

With flexible recording conditions and multiple data export interfaces, the PR series simplifies storage, analysis, and traceability—while laying a solid foundation for future system integration and process control.

Key Functional Highlights of the PR Series

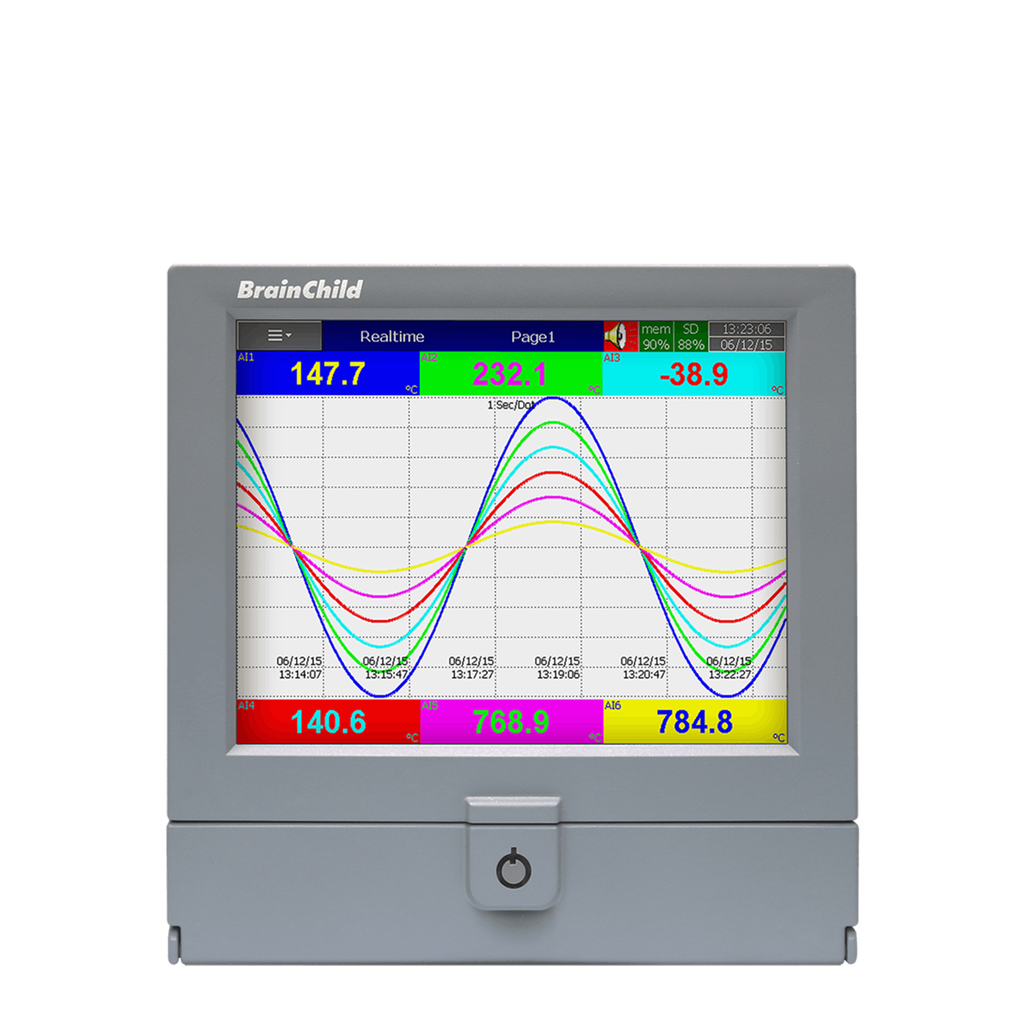

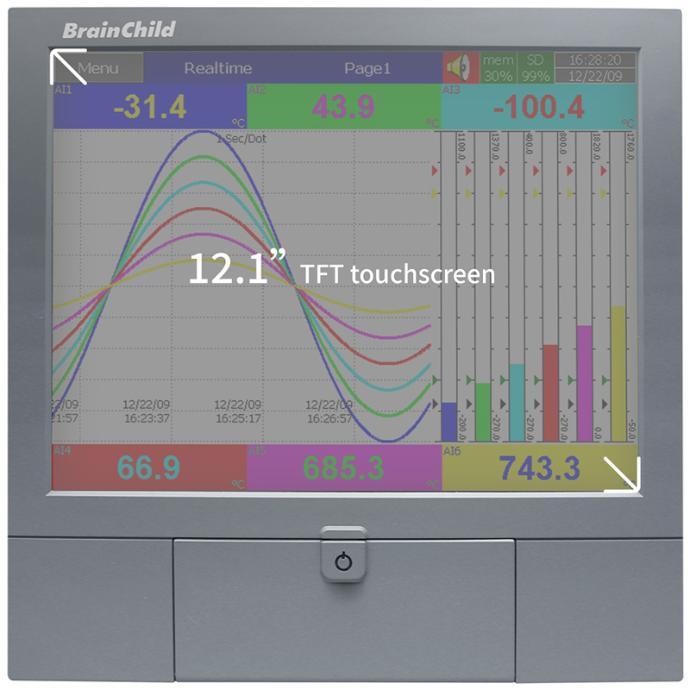

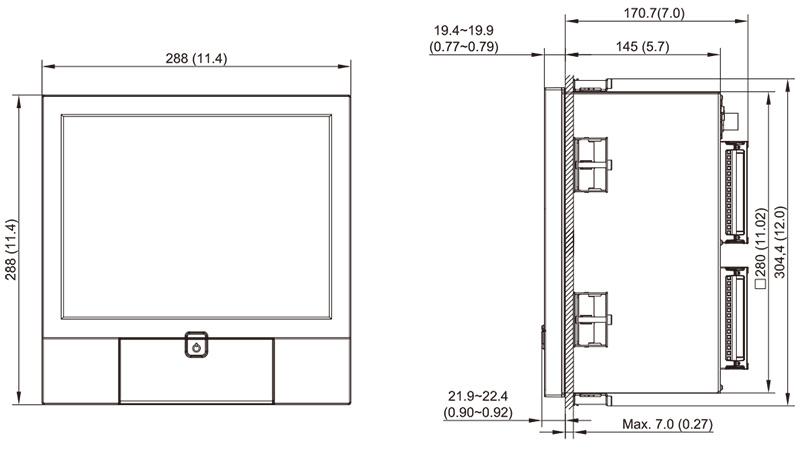

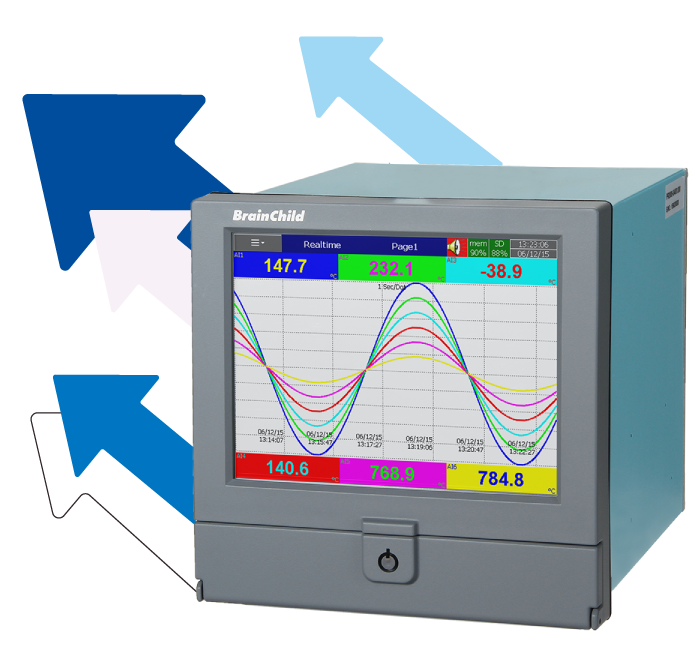

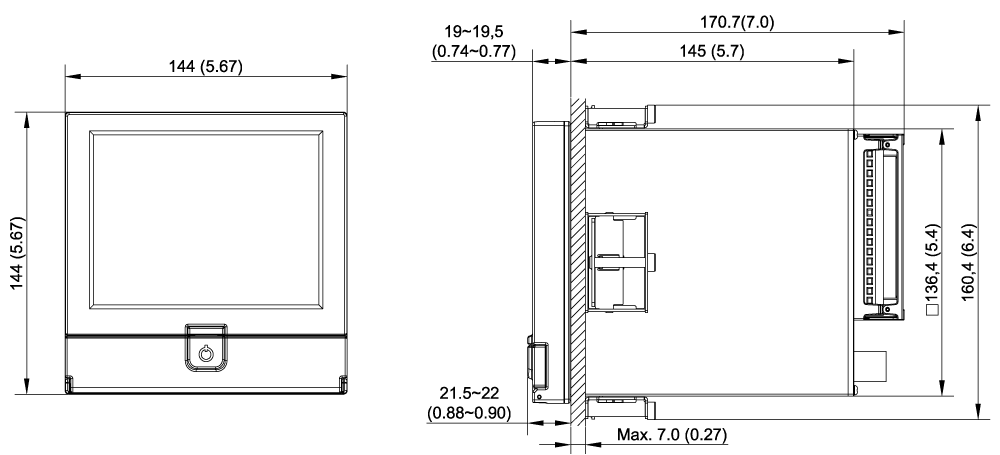

5.6-inch TFT color LCD Touchscreen Display

The 5.6-inch TFT color LCD display (640 x 480) with touchscreen functionality offers excellent visibility and an intuitive control interface. It ensures clear, easy-to-read information, enhancing user experience with seamless touch panel operation, ideal for efficient and precise control in various applications.

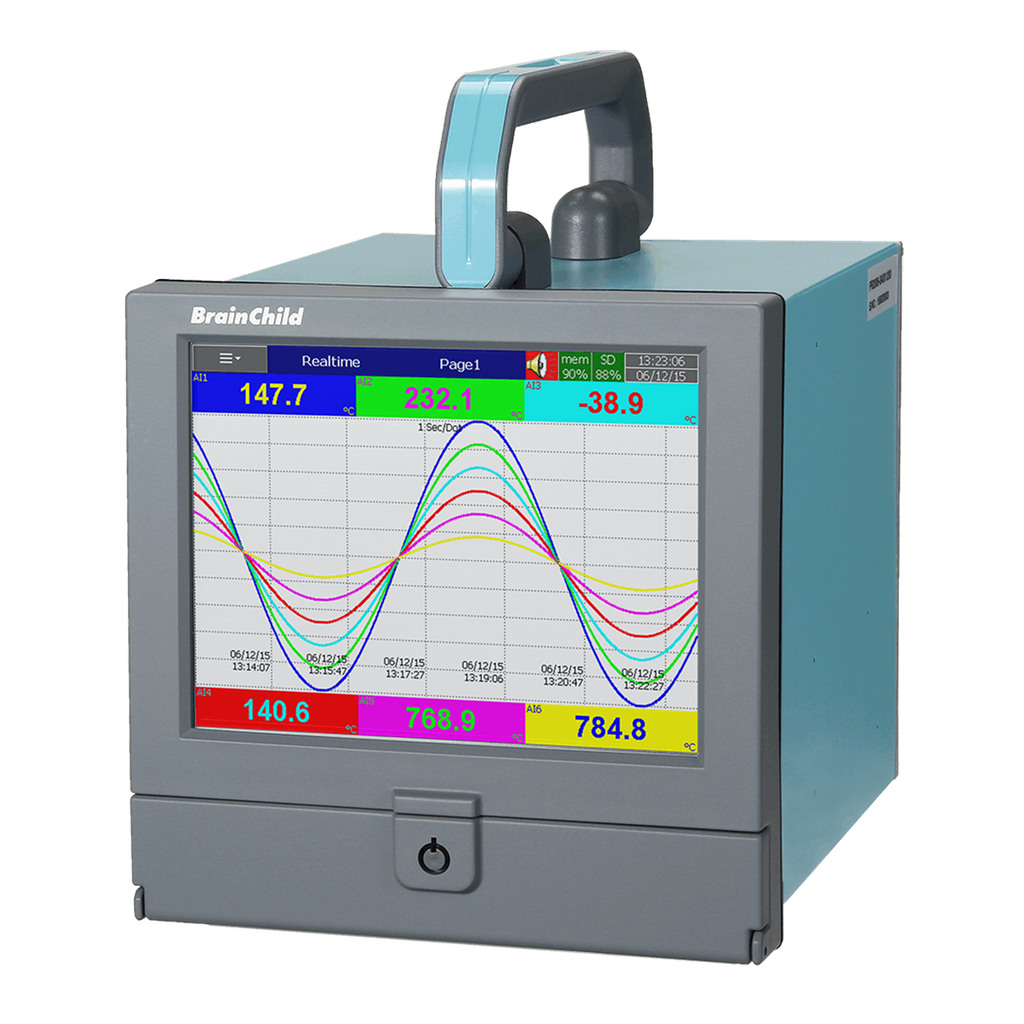

Reliable Data Recording, Anytime, Anywhere

Portable recorders with a security key offer a reliable solution for secure and efficient data logging. They are designed to meet the needs of various applications, ensuring data integrity and privacy while providing a user-friendly interface for easy operation in any environment.

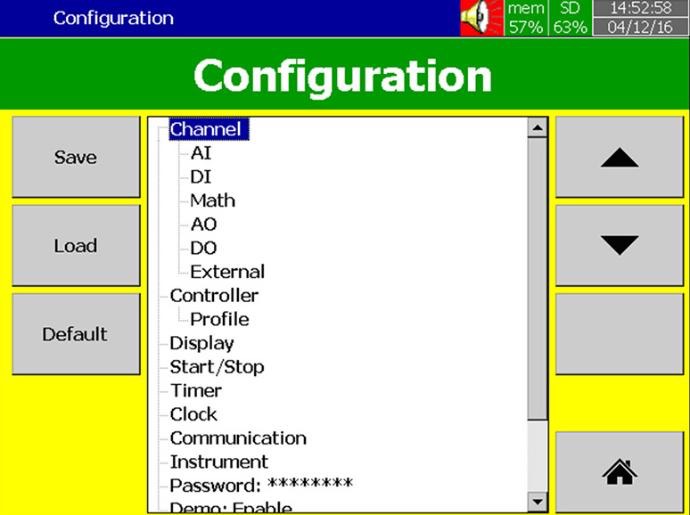

User friendly functions

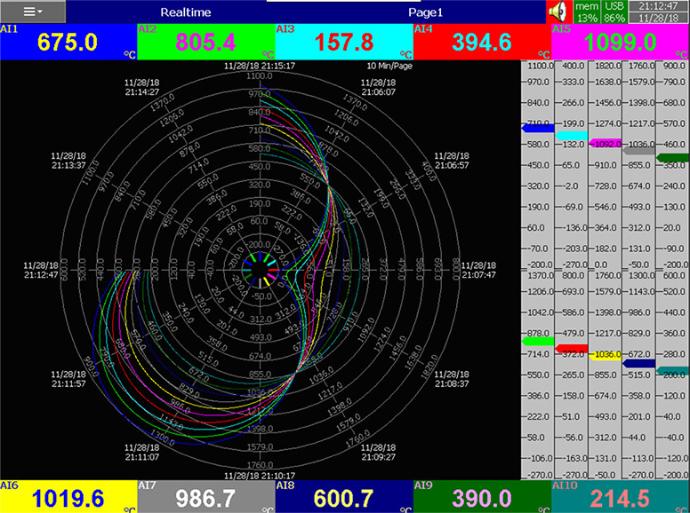

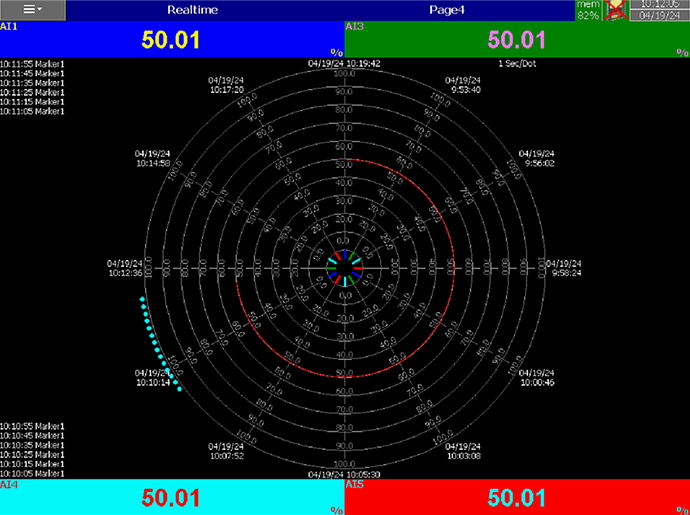

The PR Series includes an easy-to-use tree layout configuration, convenient handwriting message input, a circular display for better visibility, and both standard and plus firmware versions for enhanced flexibility and performance across various applications.

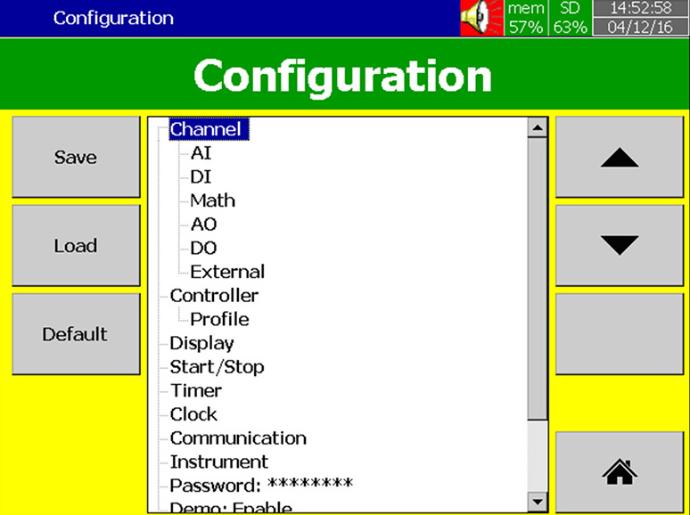

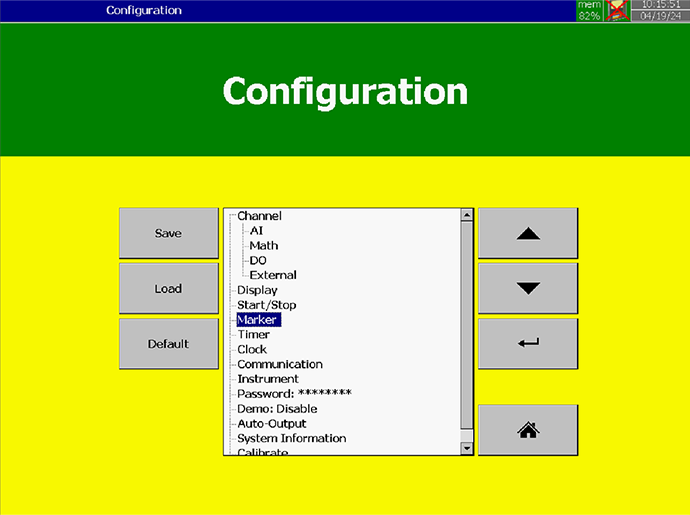

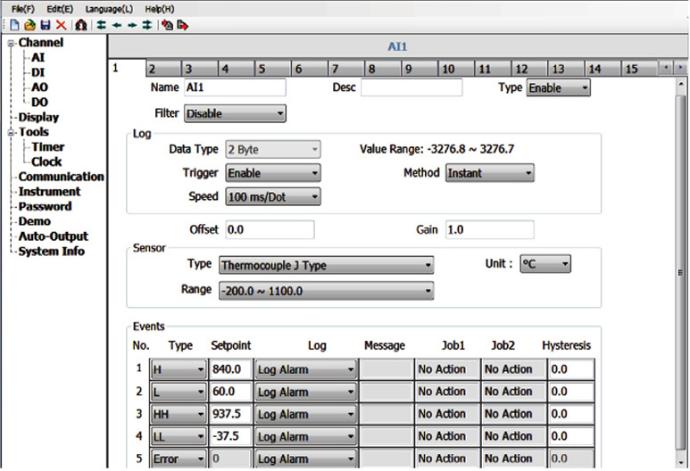

Configuration in tree layout is easy for operation

The tree layout configuration simplifies operation, allowing users to easily navigate and manage settings on the recorder.

Handwriting messages are handy users

Handwriting messages offer users a convenient and quick way to input notes directly on the recorder.

Standard version of Firmware

- Al: Analog input is offered various log speed in 1 00ms, 1, 2, 5, 10, 20, 30 Sec, 1, 2 Min/Dot.

- DI: Digital input is offered either normal Logic or high frequency Pulse.

- AO: In analog output, mA or V and its Expression can be defined.

- DO: Digital output/relay output can be enabled. Each DO card has 6 relays.

- Display: Various display speeds are available in 1 00ms, 1, 2, 5, 10, 20, 30 Sec/Dot, or 1, 2, 10, 30 Min/Page, 1, 2, 4, 8, 12 Hour/Page, or 1 Day/Page.

- Timer: Timer in Countdown, Repeat Countdown, Daily, Weekly or Monthly base, and various jobs can be defined.

- Clock: Date Style of MM/dd/yy or dd/MM/yy, Time Synchronize via Internet, and Summer Saving Time can be defined.

- Communication: Web Server and Email functions are available in Communication in Standard firmware.

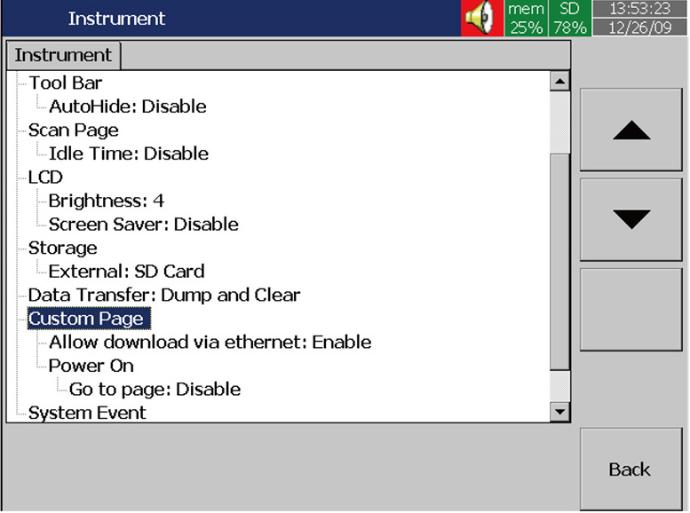

- Instrument: Brightness adjustment and Screen Saver are available in Instrument.

- Password: If Normal Security is chosen, then only one password is offered. If high Security of CFR-21 is chosen, then 9 levels of password can be defined.

- Demo: Enable or disable the demonstration.

- Auto-output: Automatic output can be set to specify the printer, to print Historical data & Report data in specified period of time.

- System information: It gives Firmware version number, Internal & External memory status, IP address, and 10 card status of each Slot.

- Calibrate: Sometimes the field calibration is required for high accuracy. In this case, a qualified engineer can do the necessary calibration.

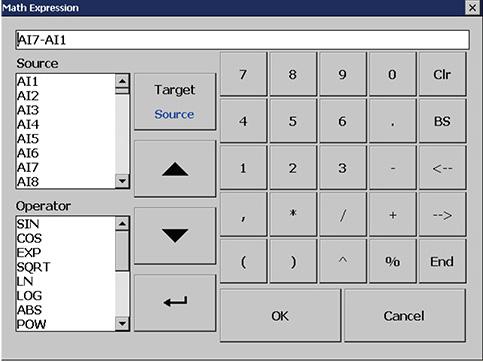

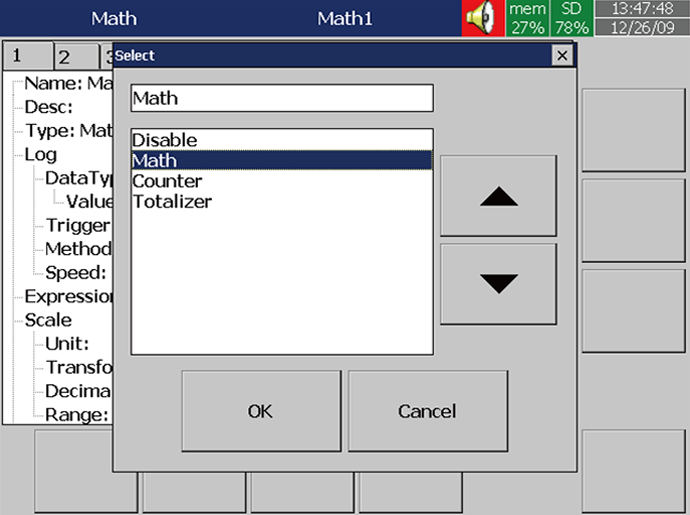

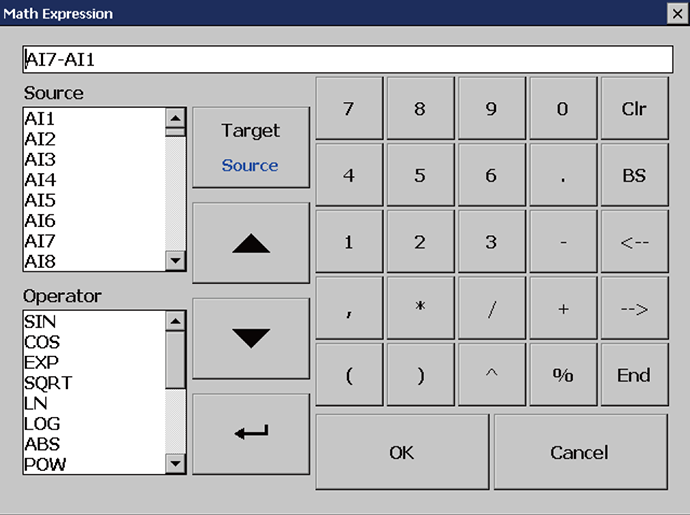

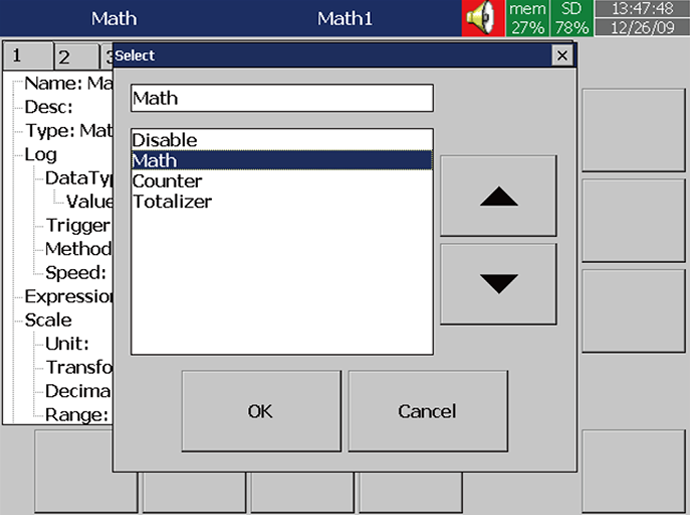

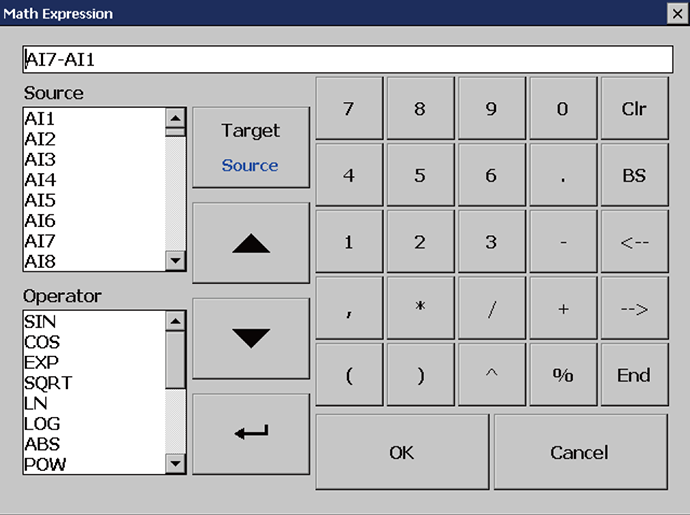

- Math: Standard version includes mathematics.

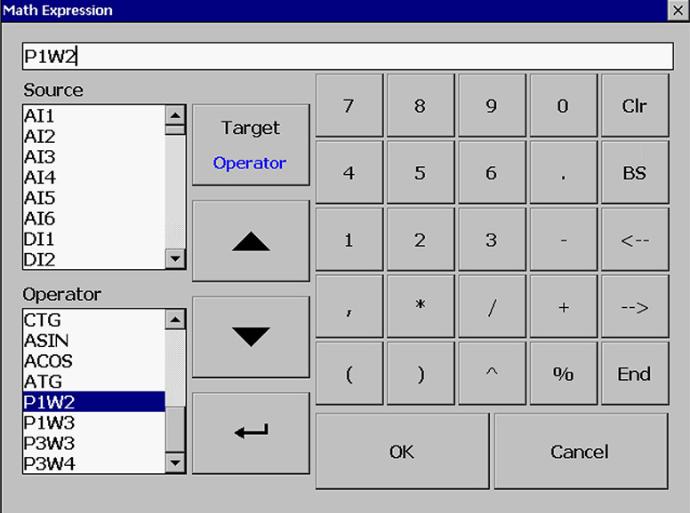

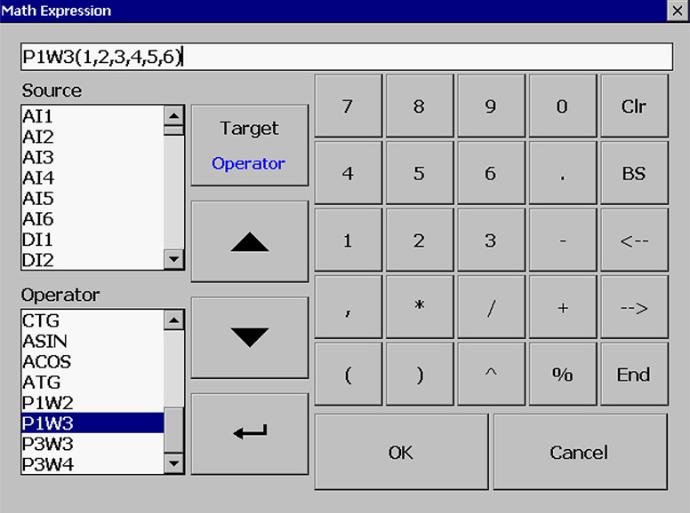

▼ Math: It includes Math, Counter & Totalizer.Math Expression is keyed in an easy way ▼

▼ Power Calculation: Calculating and recording the power usageFormulas are ready for P1W2, P1W3, P3W3, P3W4*▼

*P1W2: single-phase two wires / P1W3: single-phase three wires / P3W3: three-phase threewires / P3W4, three-phase four wires.

- Marker: Adding notifications on Real-Time View.

Plus version of Firmware

Plus versions offer more features of External Channels, Custom Display, Batch, FDA 21 CFR part 11.

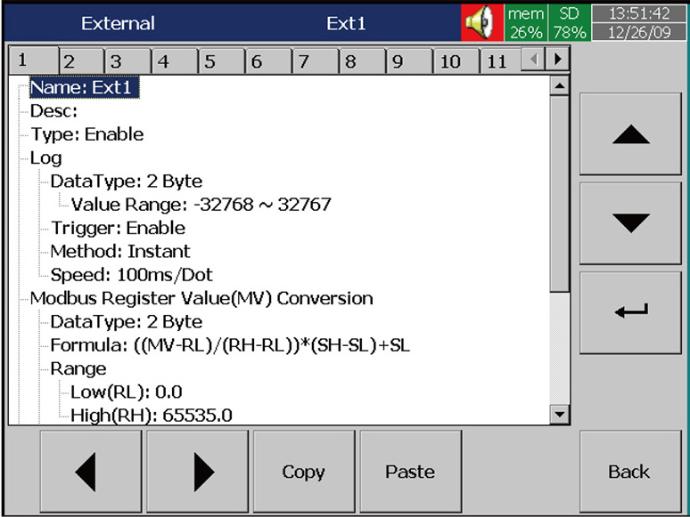

External Channels:

Besides Al & DI inputs, PR recorders accept inputs through communication called External Channels. PR10, PR20 & PR30 can work External Channels maximum up to 24, 48 & 96 respectively.

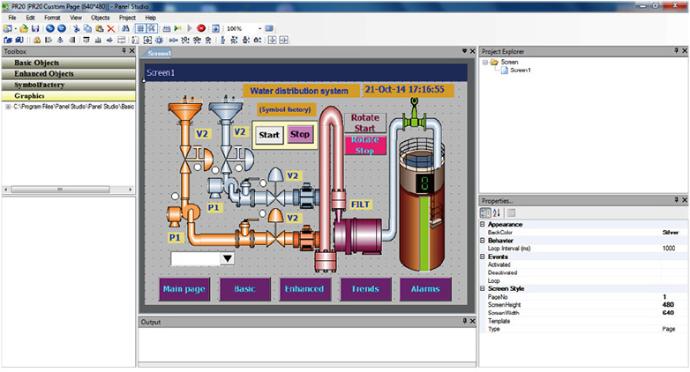

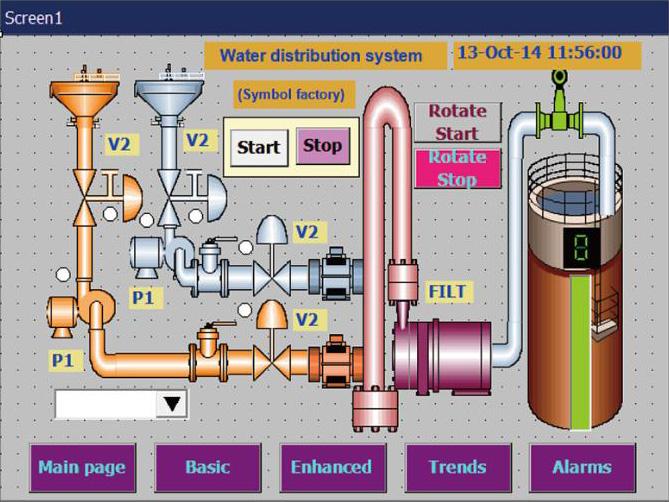

Custom Edited Display:

In Plus versions, PC software Panel Studio allows users to edit the specific display instead of standard one, and then download it onto PR recorders.

Batch:

Batch production record is constantly required for more strict production, for example food and drugs.

FDA 21 CFR part 11:

This feature is complied with U.S. Food and Drug Administration with human health concern. All data should be avoided from manipulating after recording.

Powerful functions in PC Software

The PR series PC software offers powerful functions, including easy recorder configuration and historical trend analysis. It also provides features like real-time monitoring and custom display editing, giving users the flexibility to tailor displays and monitor live data as needed.

Free basic software

It consists of two parts, which are Configuration and Historical Viewer.

I. Configuration

It is Then, easy send to do the recorder configuration on PC. Then, send the configuration files from PC to recorder.

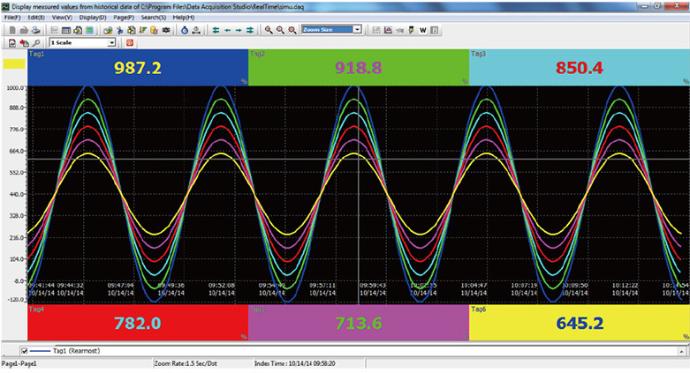

II. Historical Viewer

It can display historical trends, historical alarms, events, and then print it. It can search data by time, time period, tag, alarm, events and remarks. It also can export data in CSV format.

Extensive software Data Acquisition Studio

It consists of two parts, which are Configuration and Historical Viewer.

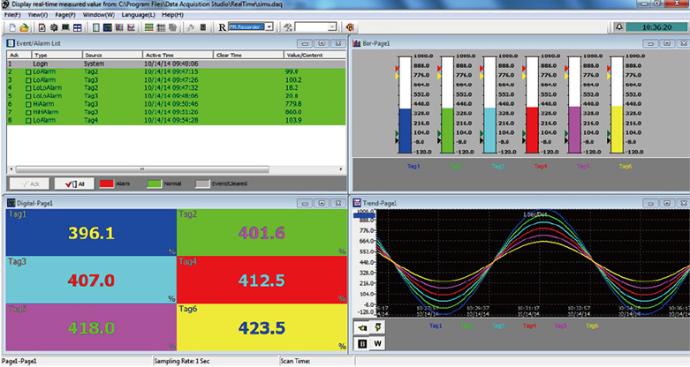

Ill. Real-time Viewer

Besides Configuration & Historical Viewer, it offers additional software Real-time Viewer for real-time monitoring.

IV. Panel Studio

If Plus version 2 or 3 of Firmware is purchased, additional software Panel Studio is offered for editing custom display. The users can use it to edit specific displays on PC first, and then download it onto recorders. The custom edited displays will be additional pages to standard ones.

Edit it on PC

Download it onto Recorders

Applications

Specification

Download

Visit Download Center to See More Documents & Tools of This Product. Visit

FAQ

Yes. It is compatible with FDA 21CFR Part11 with plus 1 firmware.

Yes. It is possible to calculate dry bulb and wet bulb temperature by using Math channel.

Yes. It is possible to calculate F0 value by using Math channel.

Yes. USB Barcode reader also can be used for data entry using USB port on the recorder.

The recorder is having high quality touch screen for the user interface. However USB Keyboard and Mouse can be connected using USB port on the recorder.