SP10 Ramp & Soak Temperature Controller

Upgraded Interface × Enhanced Functions × Greater Application Flexibility

BrainChild is set to launch the next-generation SP10 Ramp and Soak Temperature Controller, a major upgrade from the widely adopted P41 model. Designed for precision heat treatment processes, SP10 features an enhanced interface and robust control functions, ideal for applications such as industrial ovens, kilns, reflow systems, and drying furnaces.

Unlike conventional controllers that maintain a fixed temperature, SP10 enables time-based automatic temperature adjustments according to pre-set profiles, offering smart and adaptive control across multiple process stages. The controller’s six key features include:

High-Brightness LCD Display

Clearly presents real-time temperature values and current profile progress, allowing users to monitor process status at a glance.

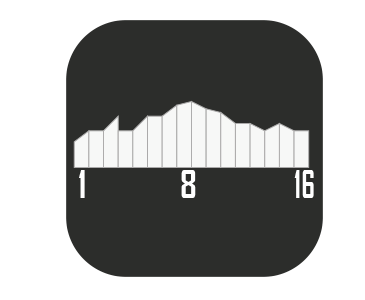

8 Programmable Profiles with 16 Segments Each

Each profile supports Ramp, Soak, and Jump segments, making it easy to build complex, multi-stage thermal processes with flexibility.

Setpoint Retransmission

Allows SP10 to transmit its setpoint (SV) to other controllers with Remote Set Point functionality—such as BrainChild’s C Series—for seamless multi-device synchronization.

3 PID Parameter Sets + Autotune Function

Configure separate PID settings for different temperature zones. The built-in Autotune function automatically calculates optimal parameters, ensuring fast and stable control under various environments.

Event Input Capability

Supports digital input triggers to remotely start, pause, or reset alarms—perfect for automation integration and remote operation.

Flexible Relay Output Options

Up to 4 relay outputs can be configured as secondary control outputs or alarms. Each segment can turn outputs ON/OFF independently—for example, activating a cooling fan during a soak-to-cool transition to speed up heat dissipation.