Features

- Individual scaling for each output channel

- 15-bit D/A conversion with ±0.05% accuracy

- 200ms fast sampling rate

- Programmable low-pass digital filter

- Supports thermocouples, RTD, current, voltage

- Dual LCD display with high brightness

- One configurable digital input (DI)

- Micro USB port for PC setup & firmware update

- 3-point output calibration and adjustment

- Manual control mode for testing

- Lockout protection with multi-level security

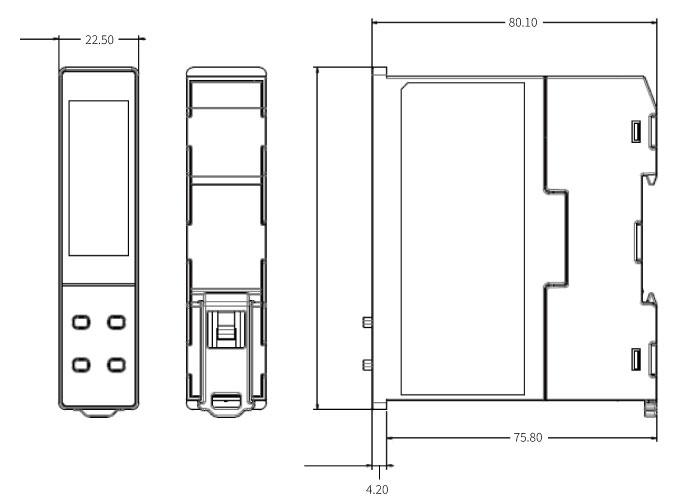

- DIN rail mounting design

- Wide power supply range (11–40VDC / 90–250VAC)

- Conforms to UL, CE, EN61010-1 standards

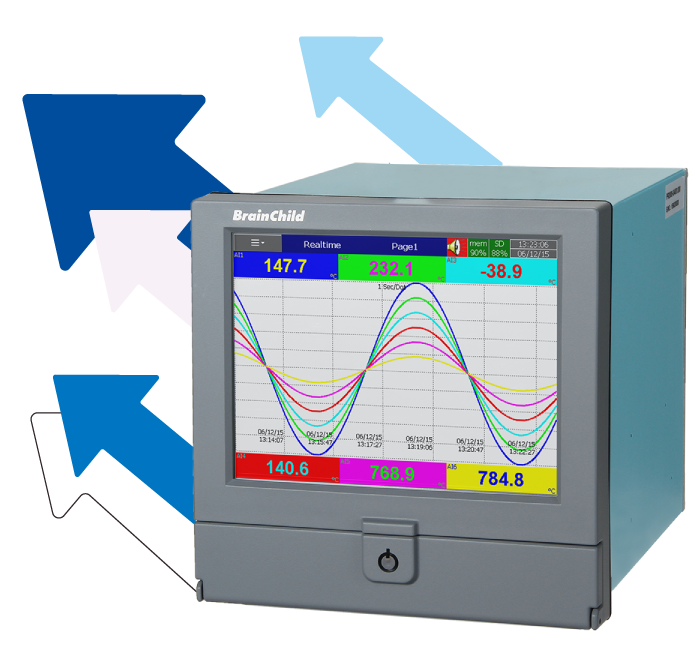

RSC Signal Conditioner for Industrial Automation

Universal input, 3-way retransmission, RS-485 communication

The BrainChild RSC signal conditioner is a compact, DIN-rail mountable module designed for precise signal conversion and isolation. It supports universal input for various signal types including thermocouples, RTDs, current (mA), and voltage (V). With its 18-bit high-resolution A/D converter, the RSC ensures fast and accurate signal processing. It provides up to three independent analog retransmission outputs with 15-bit D/A resolution, ideal for complex industrial control systems. Additional features such as RS-485 Modbus RTU communication, square root calculation, and programmable digital filtering make it a powerful solution for industrial automation and process signal conditioning.

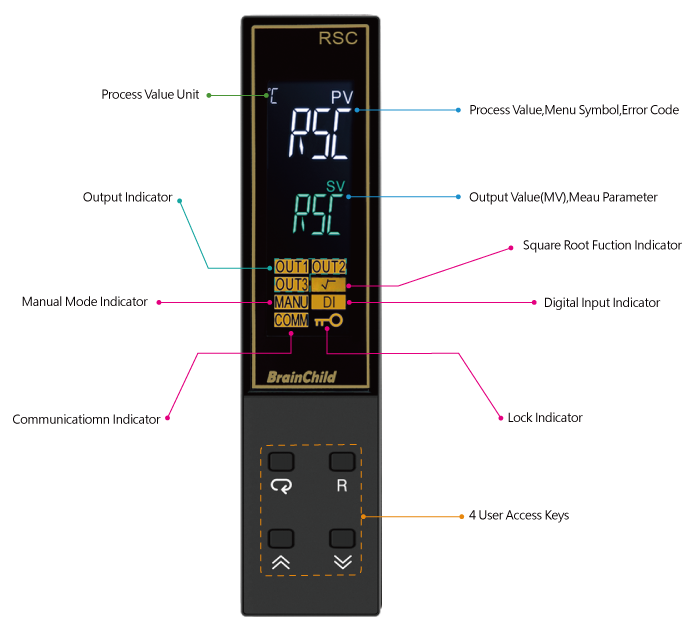

RSC Panel Interface | Clear Dual Display & Keys

Dual-line LCD, four-key control, status indicators

The BrainChild RSC signal conditioner features an intuitive and reliable panel interface designed for fast configuration and daily monitoring. At the core is a dual-line high-brightness LCD display, which provides crisp, real-time visibility of the process value (PV) and user-selected menu parameters or set values (SV). This enables engineers and technicians to check live readings and adjust settings without external tools.

The interface includes four tactile control keys: Scroll/Enter, Up, Down, and Reset, making it easy to navigate the multi-layer menu structure, perform fine-tuned adjustments, and quickly return to the home screen. The Scroll/Enter key allows seamless parameter selection and confirmation, while Up and Down keys offer precise control during setup. The Reset key is essential for restoring normal operation or exiting configuration mode.

To enhance usability, the panel is equipped with multiple visual status indicators, including icons for output channels (OUT1~OUT3), manual mode activation, digital input activity (DI), square root calculation (SQRT), and parameter lock status (LOCK). These symbols give operators immediate visual feedback on system status, minimizing operational errors.

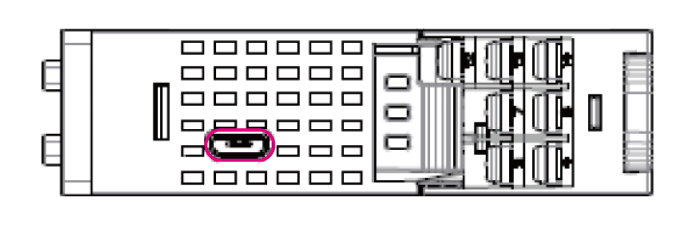

For added convenience, a micro USB port is integrated discreetly on the front panel, allowing offline configuration, firmware upgrades, and automated calibration via PC, without requiring disassembly or front-panel input. This modern interface design supports both on-site usability and maintenance flexibility, making the RSC suitable for diverse industrial automation environments.

LCD Display | High-Brightness for Industrial Use

Anti-glare, high-contrast dual display for clear visibility

The LCD display on the RSC signal conditioner is engineered for high brightness and optical clarity, ensuring reliable visibility even in brightly lit industrial environments. Built with anti-glare coating and high-contrast segments, the display remains sharp and legible from various angles and lighting conditions.

Whether mounted inside a control cabinet or used on an exposed panel, the screen’s white backlight and crisp segmented characters help technicians and operators quickly recognize displayed values and messages. The layout emphasizes readability and eye comfort, reducing misinterpretation during long operation hours.

By combining clarity, durability, and minimal reflection, the RSC’s LCD is optimized for industrial process monitoring, offering an interface that remains dependable and easy to read across all applications

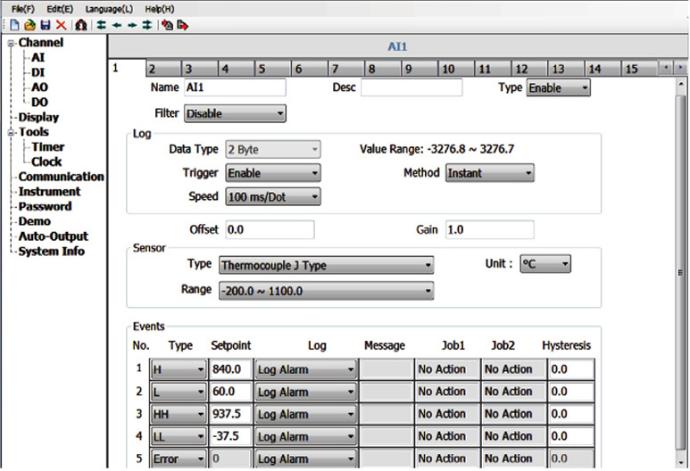

RSC Input Types | Thermocouple, RTD, mA, V

18-bit A/D conversion, universal input compatibility

The RSC signal conditioner features a universal input interface, supporting a wide range of industrial signal types. It accepts thermocouples (J, K, T, E, B, R, S, N, L, U, P, C, D), RTDs (PT100 DIN/JIS), as well as linear current (4–20 mA, 0–20 mA) and linear voltage (0–5V, 1–5V, 0–10V) signals. The input signal is processed by an 18-bit high-resolution A/D converter, ensuring accurate and stable measurement across applications.

For linear signals, users can define custom input scaling ranges (INLO/INHI) to match specific process sensors. Input readings are further stabilized by a programmable digital filter, and enhanced with square root transformation for flow-type inputs.

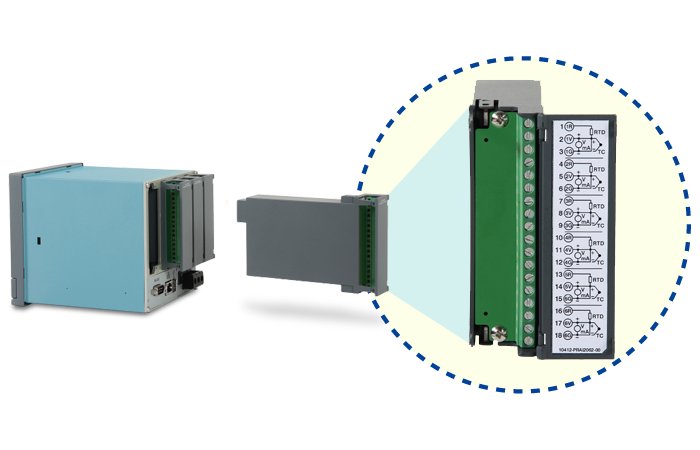

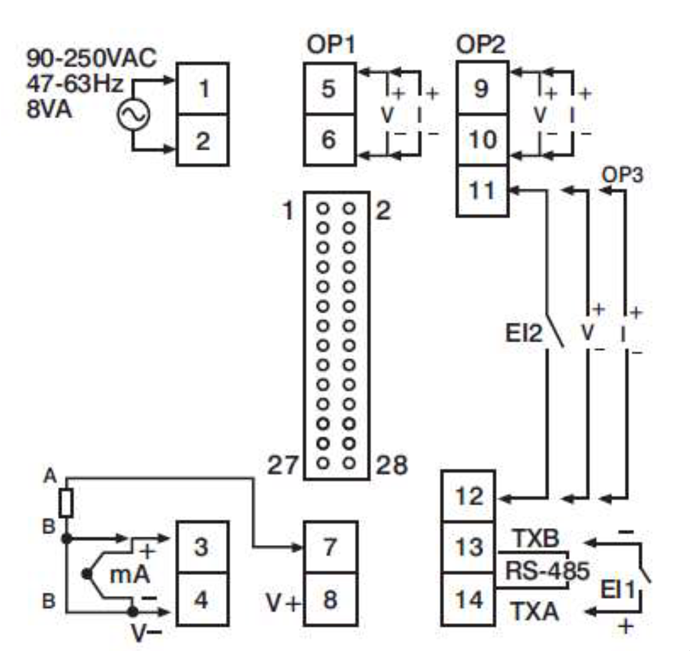

RSC Output Options | 3 Analog Channels & DI

15-bit D/A resolution, 4–20 mA / 0–10 V selectable

The RSC conditioner supports up to three analog retransmission outputs, configurable via modular options. Each output channel supports 4–20 mA, 0–20 mA, 0–10V, 1–5V, or 0–5V ranges, with a resolution of 15-bit D/A conversion and ±0.05% of span accuracy. All outputs are electrically isolated and can be scaled independently using parameters ANL/ANH for each channel.

In addition, the RSC offers one configurable digital input (DI) as an option, allowing logic-level triggering for external control actions or mode switching. All output types are programmable and stabilized with zero/span calibration and fast response time (0.1 sec).

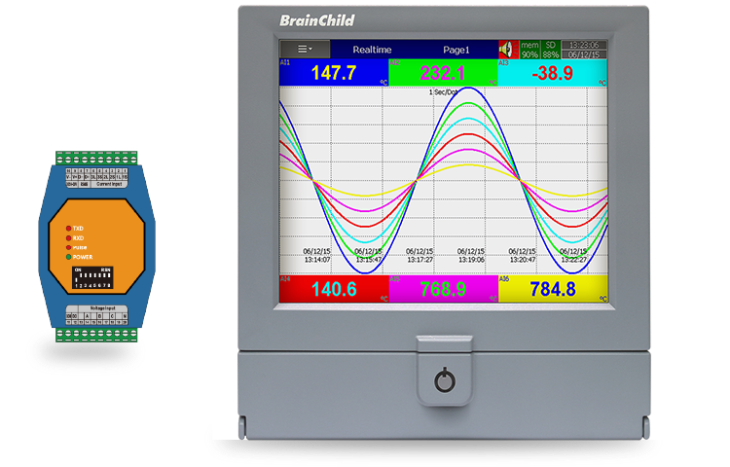

RSC Programming Port | USB for Easy Setup

Support firmware upgrade, auto config & testing

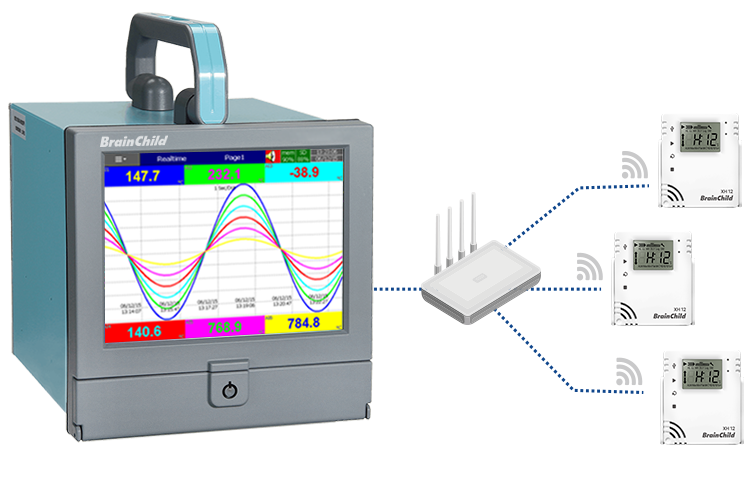

The RSC signal conditioner is equipped with a micro USB programming port on the front panel, designed for convenient PC-based configuration, firmware upgrades, and automated calibration or testing procedures. This interface enables fast, accurate setup without the need to navigate the device's front-panel buttons, greatly enhancing efficiency during installation or maintenance.

Using the optional PA98-1 USB programming adapter and CC98-1 programming cable, users can connect the RSC unit to a PC running the BC-Set configuration software. This allows engineers to download or upload settings, update the firmware, and perform full diagnostic checks—especially valuable for high-volume deployments or OEM integration.

The programming port is electrically isolated from the I/O circuitry, ensuring safety and reliability during connection. It is intended for offline use, meaning users should not access the port while the device is actively operating in the control loop.

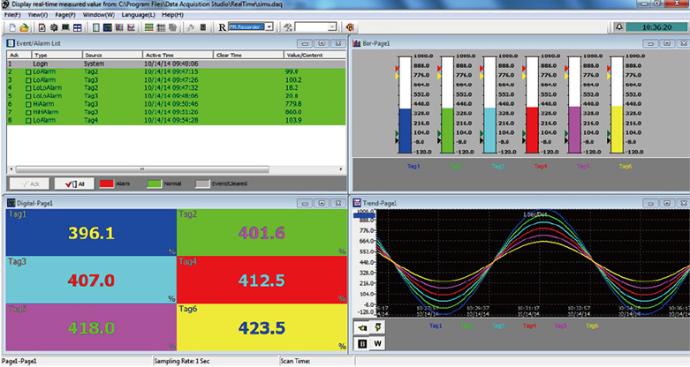

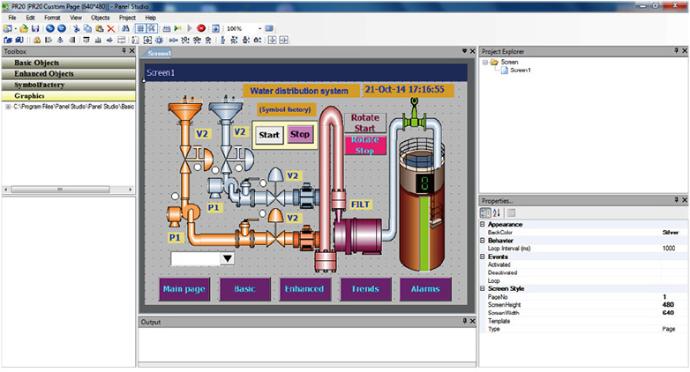

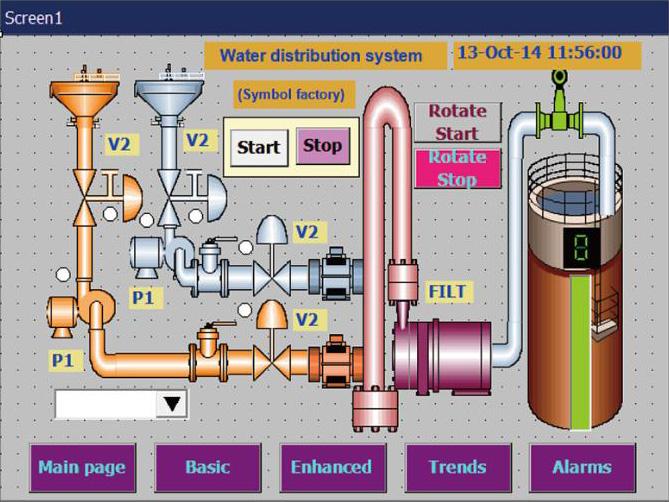

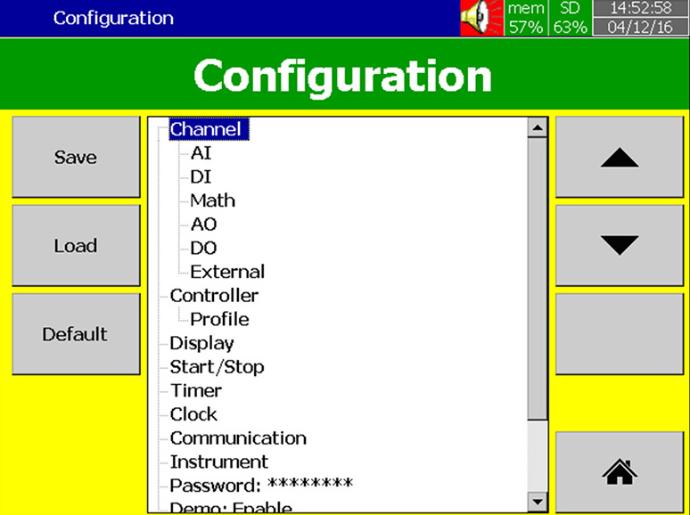

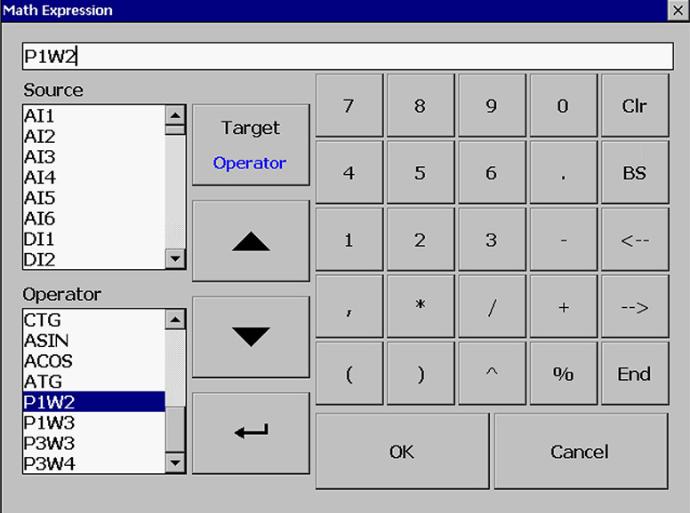

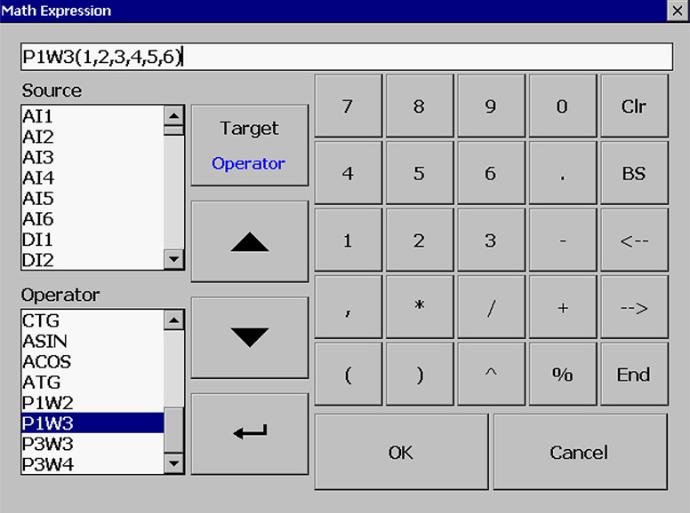

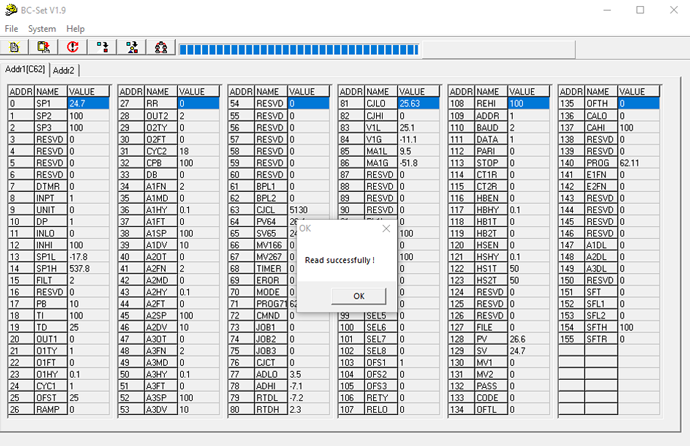

BC-SET Pro Configuration Software

Easy parameter setup, backup and firmware upgrade

BC-SET Pro is the official configuration software developed by BrainChild for its over-temperature protection controllers. With a streamlined and intuitive interface, the software allows users to connect via USB programming cable and quickly configure control parameters. It supports efficient parameter editing, setting duplication between devices, and firmware upgrades to maintain device performance and stability. BC-SET Pro also enables offline configuration with the ability to save and manage multiple profiles, making it ideal for production environments, system deployment, and ongoing maintenance. Whether for new setup or existing system adjustment, this tool helps engineers and technicians simplify workflow, reduce setup time, and ensure consistent configuration across all devices.

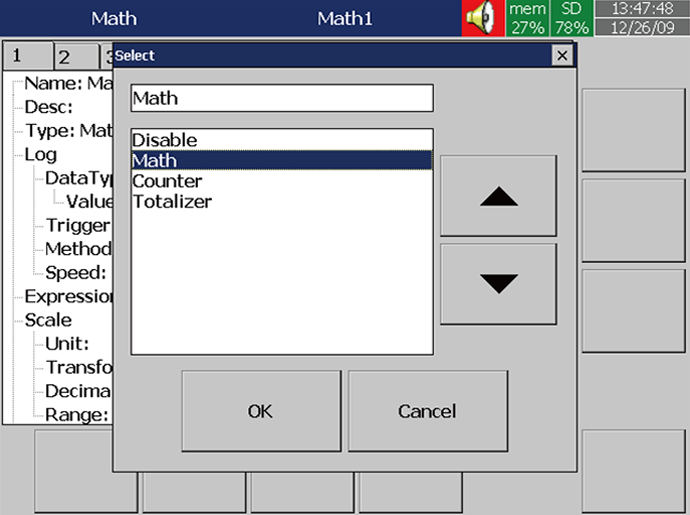

Batch Read/Write for Multiple Controllers

BC-SET allows users to connect multiple controllers of the same model and perform batch parameter read/write by defining a node address range. This feature significantly streamlines configuration in OEM or multi-device environments.

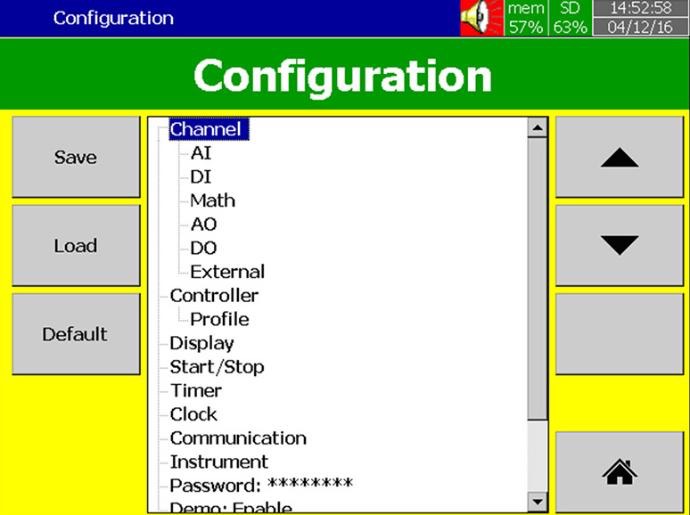

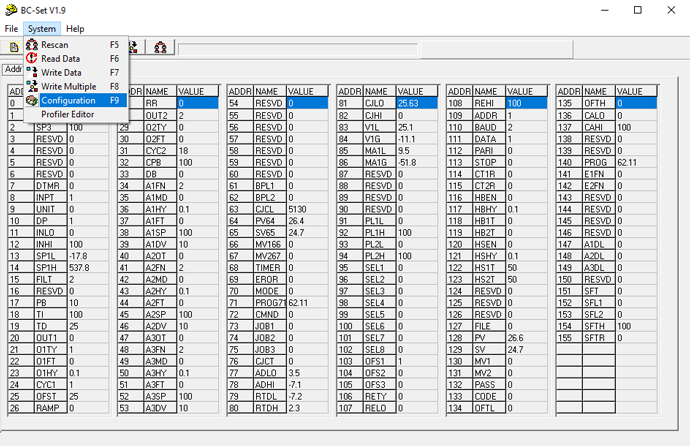

Clear and Accessible System Menu

The system menu offers quick access to key operations like Rescan (F5), Read Data (F6), Write Data (F7), Write Multiple (F8), and Communication Settings (F9). Built-in hotkeys support fast, efficient navigation.

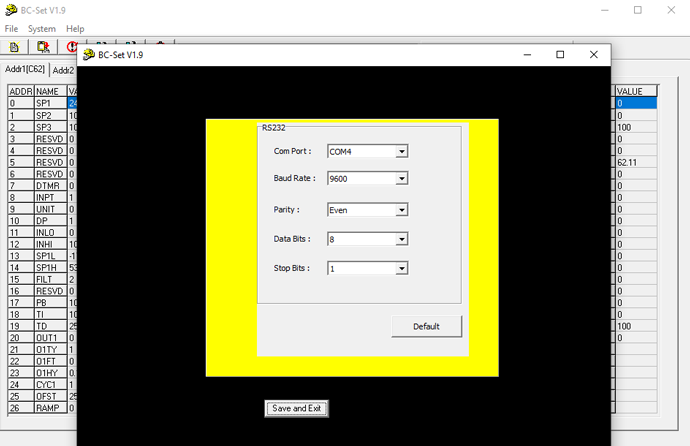

Intuitive Communication Setup Interface

The communication settings window lets users define COM port, baud rate, parity, data bits, and stop bits — with a “Default” button for quick reset and “Save and Exit” to finalize setup. Designed to reduce setup errors.

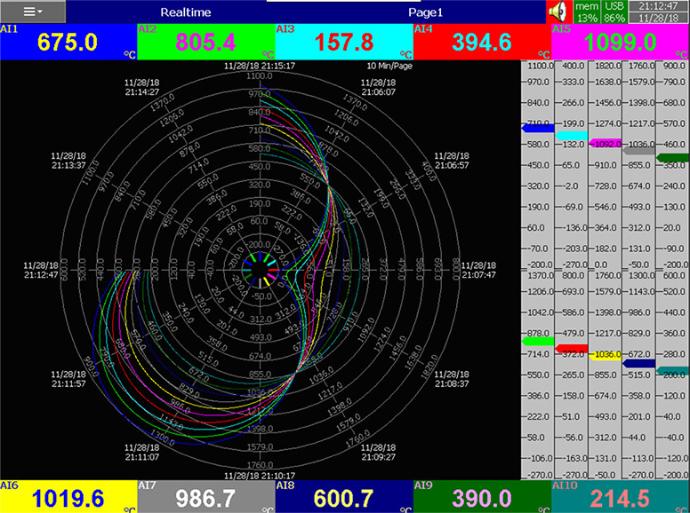

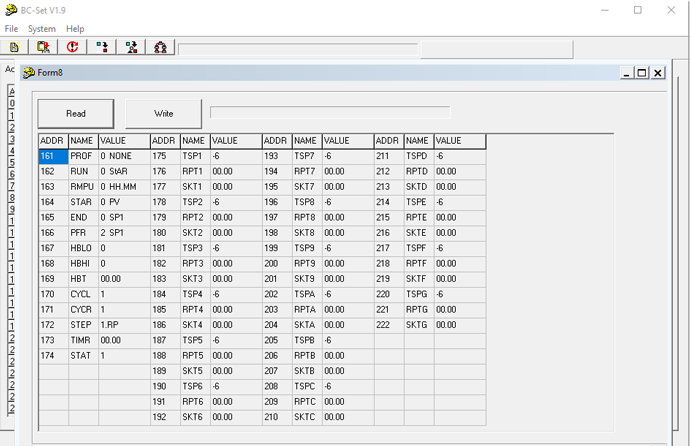

Visual Profile Editor for Programmable Controllers

For controllers with profile functionality, BC-SET provides a graphical editor to configure temperature ramp/soak segments. Users can easily read, modify, and write profile parameters for precise thermal process control.

Applications

Specification

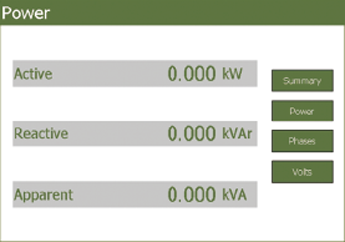

Power

Signal Input 1

Digital Input (DI1 or DI2)

Analog Retransmission Output 1 /Output 2 / Output 3

Data Communication

User Interface

Programming Port

Digital Filter

Environmental and Physical Specifications

Approval Standards

Download

Visit Download Center to See More Documents & Tools of This Product. Visit

FAQ

The RSC supports universal input signals, including thermocouples (13 types), RTDs (PT100 DIN/JIS), current signals (4–20 mA, 0–20 mA), and voltage signals (0–5V, 1–5V, 0–10V). Signal scaling, filtering, and square root transformation are also supported.

The RSC provides up to three independent analog retransmission outputs, each configurable as current or voltage output. Users can select from 4–20 mA, 0–20 mA, 0–10V, 1–5V, or 0–5V, all with 15-bit D/A resolution and ±0.05% accuracy.

Yes. With the optional PA98-1 USB programming adapter and BC-Set software, users can configure parameters, update firmware, and perform diagnostics via the micro USB programming port.

The front panel is rated IP65 when properly mounted, while the housing and terminals are IP20. The device is designed for indoor use only and should be installed inside a control cabinet.

Yes. The RSC offers an optional digital input (DI1 or DI2) that can be used to trigger events such as mode switching, manual control, or parameter reset, depending on configuration.

Brouchure_RSC_EN

Brouchure_RSC_EN Software_BC-Set Pro_V1.1.0.12(above V4.0)

Software_BC-Set Pro_V1.1.0.12(above V4.0)