Features

- Multi-color LCD for clear status display

- 4-key keypad with dual 4-digit display

- USB port for easy setup and firmware update

- Supports 2 relay or analog output channels

- Built-in CT input for heater break alarm

- Event input available for external trigger

- High accuracy: ±0.05% for linear signals

- Soft-start prevents overshoot at power-up

-

Bumpless Transfer on sensor failure

- Auto/manual mode with transfer on error

- First-order digital filter, time adjustable

- Sensor break detection with fast response

- Supports Modbus RTU (RS-485, slave mode)

- Certified with UL, CE, RoHS, REACH, WEEE

- Panel mount design, 48 × 24 mm front panel

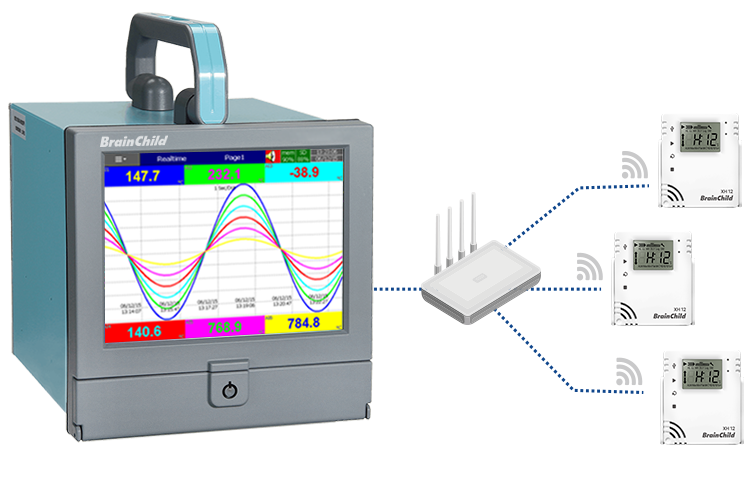

C22

High-Precision PID Temperature Controller

Compact Size, Powerful Features, Reliable Temperature Control

The C22 is a compact PID temperature controller engineered for high-precision industrial temperature regulation. Designed to support a wide range of thermocouples, RTDs, voltage and current inputs, the C22 delivers fast 200ms sampling and 18-bit input resolution for accurate and stable performance.

Ideal for space-constrained equipment such as ovens, lab instruments, and automated machinery, the C22 combines fuzzy + PID control, soft-start functionality, and sensor break detection to ensure reliable operation. Optional RS-485 Modbus RTU communication and analog output make integration with industrial control systems seamless.

Whether you're upgrading legacy controllers or designing new automation systems, the C22 provides the reliability, flexibility, and accuracy required for modern thermal control applications.

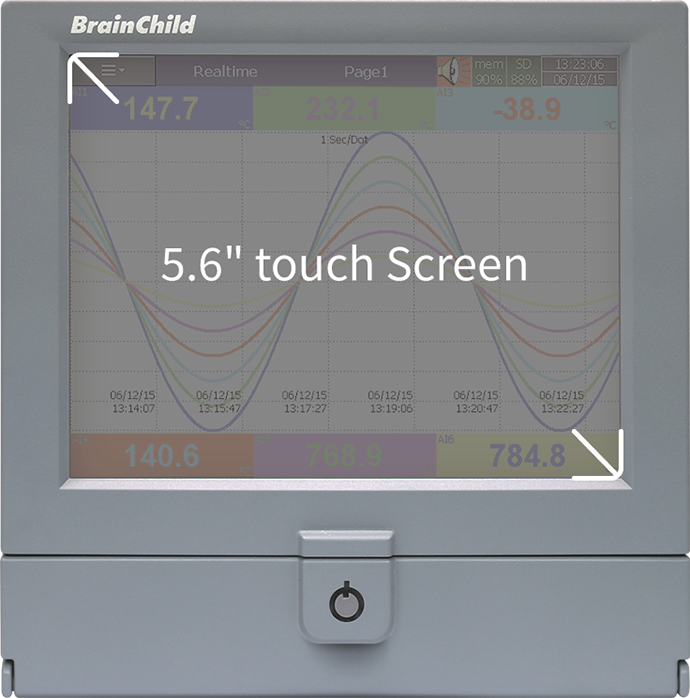

Clear and Compact Front Panel Design

Dual digital displays with intuitive layout in a 48×24 mm panel

C22 features a simple and ergonomic 4-key keypad combined with dual digital displays, making it easy for users to navigate settings, monitor values, and make quick adjustments. The upper and lower displays show process values and setpoints simultaneously, reducing the need for switching screens. Designed with operator efficiency in mind, the interface shortens learning curves and ensures smooth integration into any workflow — even in fast-paced industrial environments.

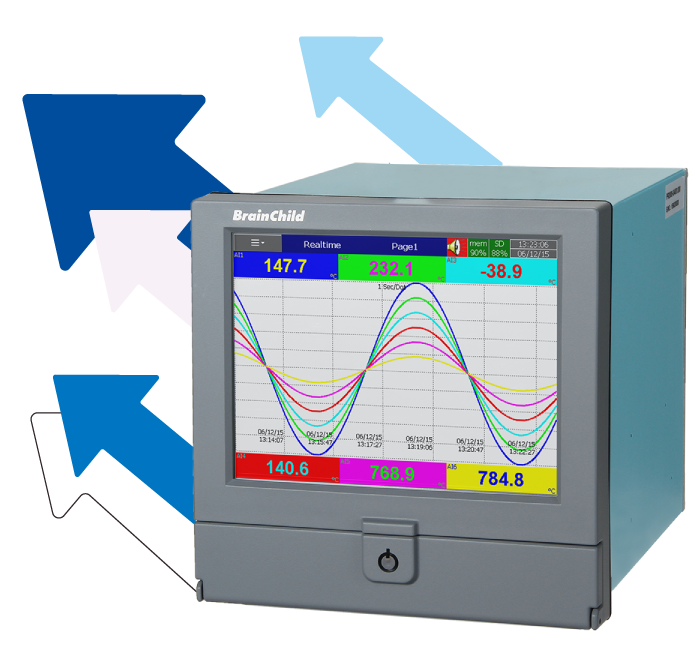

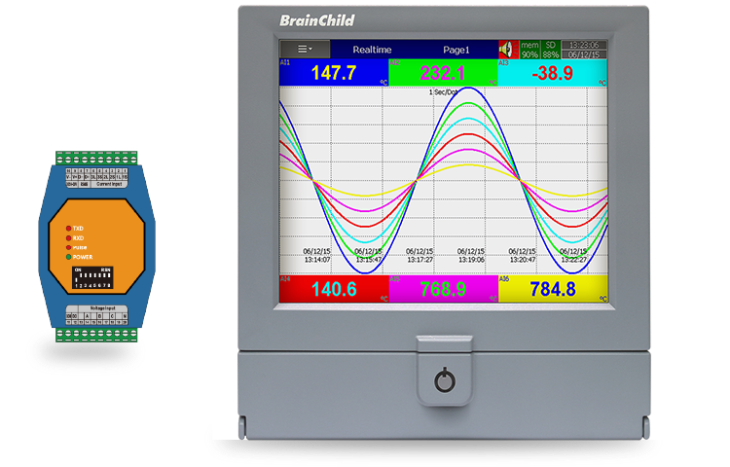

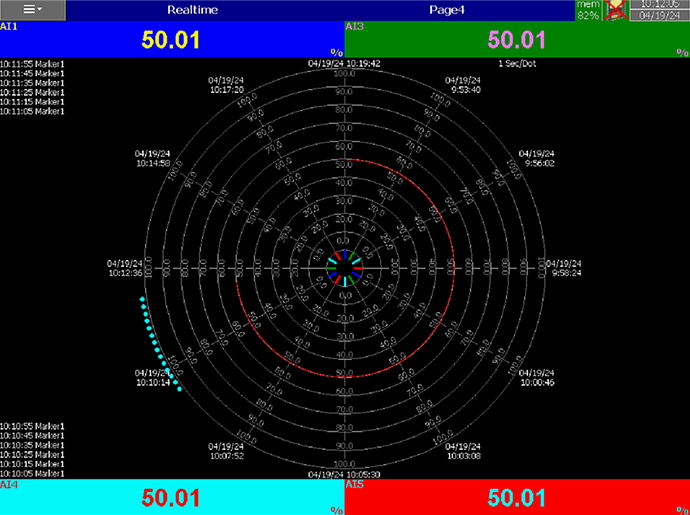

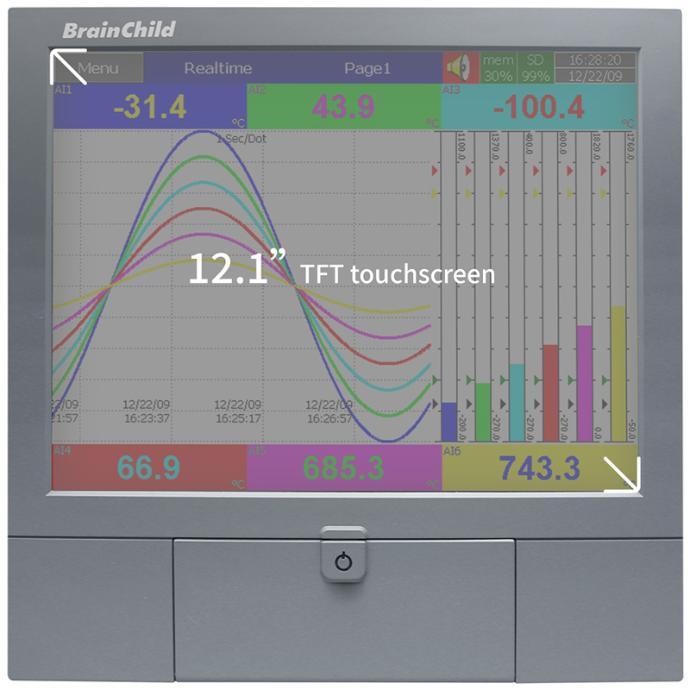

High-Brightness Multi-Color LCD Display

Color-coded visual alerts for clear and safe operation

The Core Series features a high-brightness LCD screen with multiple color indicators, enhancing visibility in various lighting conditions — even under harsh industrial environments. Each color is intelligently assigned to represent key system statuses such as normal operation, alarm, or output activity, allowing operators to identify conditions at a glance. Whether viewed on-site or from a distance, the display ensures quick recognition, reduced errors, and improved response time.

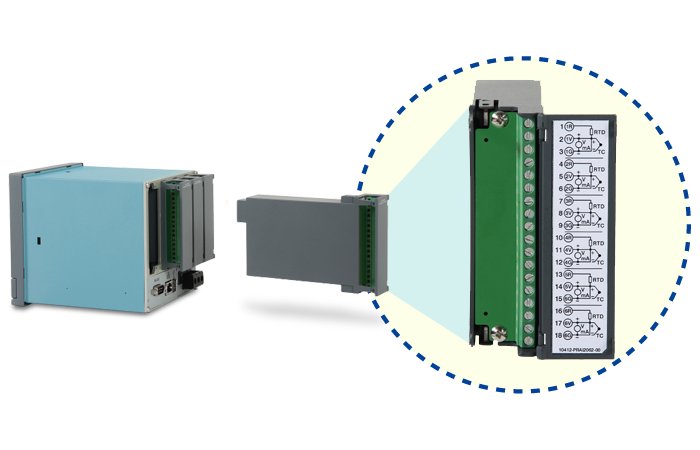

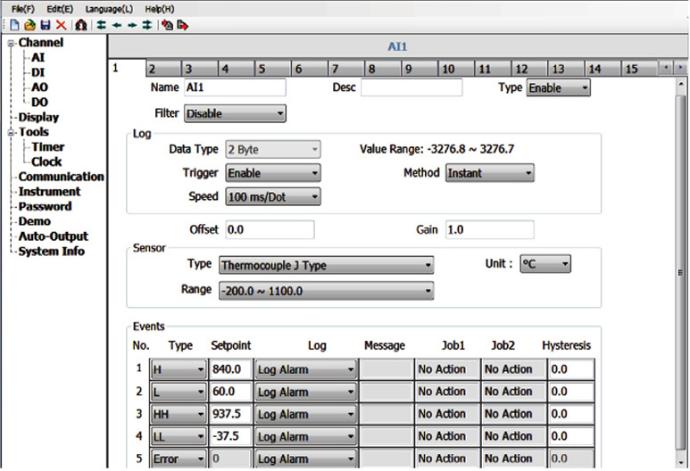

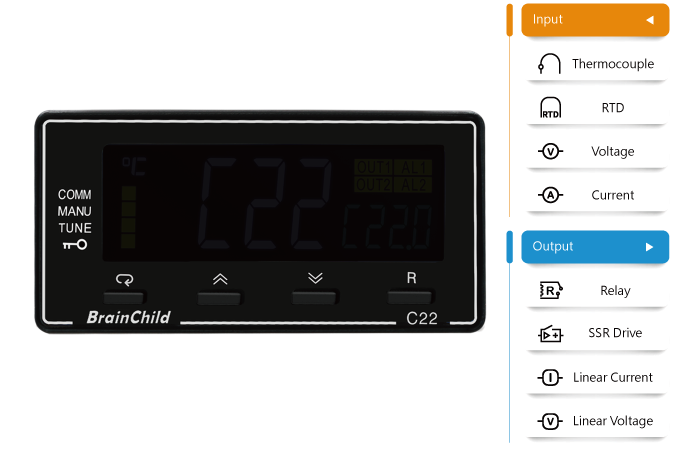

Universal Input for Various Sensor Types

Supports thermocouple, RTD, voltage, and current inputs

The Core Series controllers support a wide range of input types, including thermocouples (J, K, T, E, etc.), RTDs (PT100 DIN/JIS), voltage (0–10 V), and current (4–20 mA) signals. This universal input design makes them compatible with most industrial temperature sensors, ensuring flexible integration across different applications.

Flexible Output Options for Control and Alarms

Relay, SSR, and analog output available

Core

Series models offer versatile output options, including relay contact, SSR drive (pulsed voltage), and analog output (4–20 mA or 0–10 V). Depending on the model, up to two output channels can be configured for control or alarm functions. Optional features like CT input and event input further enhance system responsiveness and integration.

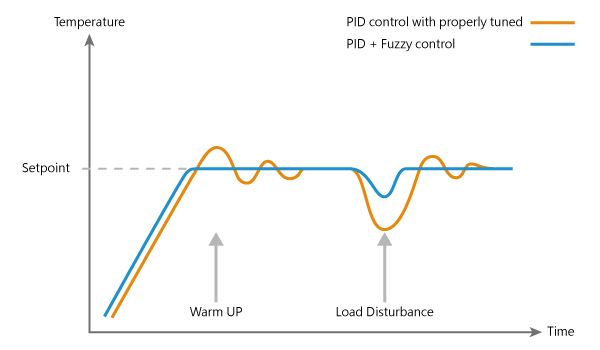

Fuzzy PID Technology

Smarter Control with Less Overshoot and Faster Response

Fuzzy logic is combined with traditional PID control to deliver smarter and more adaptive temperature regulation. Unlike standard PID controllers that require manual fine-tuning for each application, fuzzy PID dynamically adjusts control responses based on real-time process behavior. The result is faster stabilization, reduced overshoot, and improved resilience to disturbances—ideal for processes where precision and speed are critical.

Built-in Programming Port for Fast Configuration

Micro USB interface streamlines setup and firmware upgrades

The Core Series is equipped with a built-in micro USB programming port that allows users to configure parameters and update firmware directly from a PC. With the optional USB configuration cable and dedicated software, engineers can complete setup in minutes—without powering the device through system wiring. This feature greatly reduces installation time, simplifies maintenance, and ensures flexible deployment across various projects.

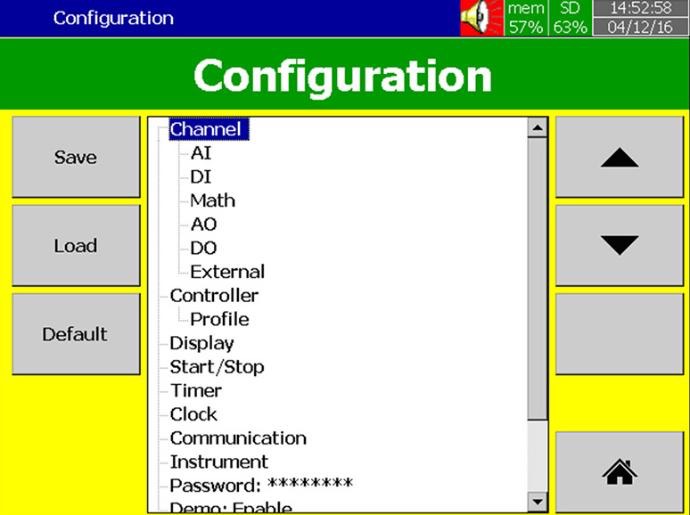

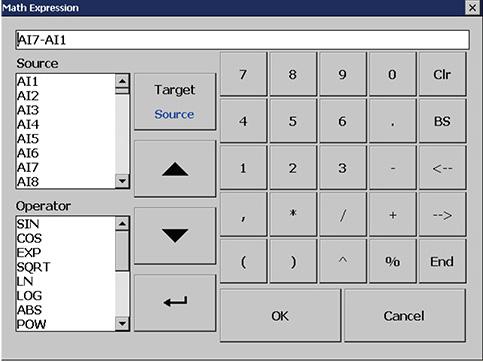

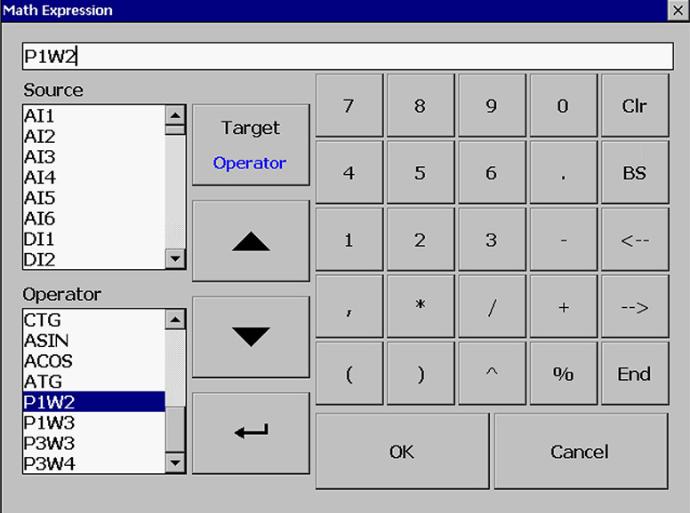

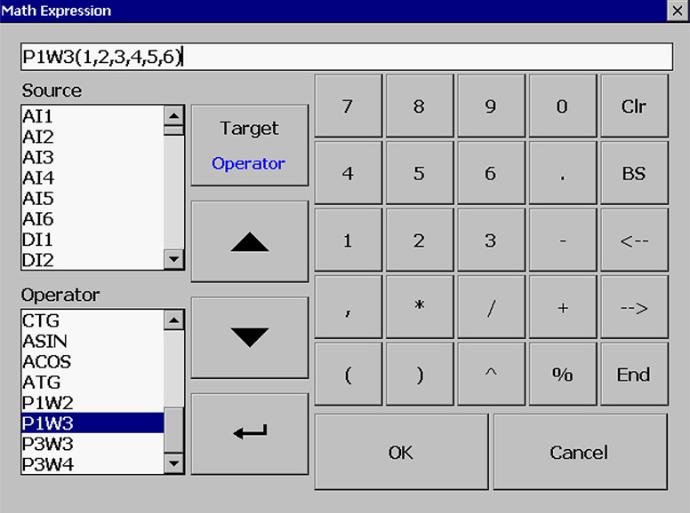

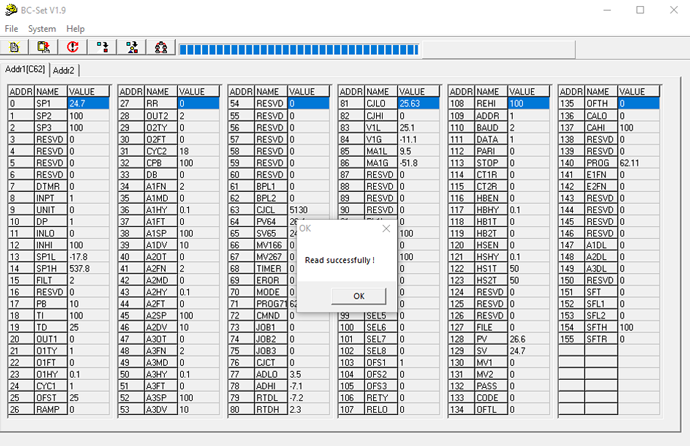

BC-SET Pro Configuration Software

Easy parameter setup and firmware upgrade for Core Series controllers

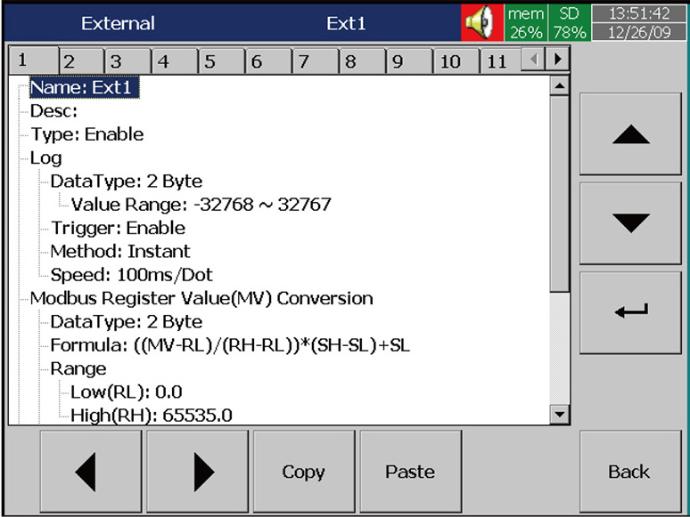

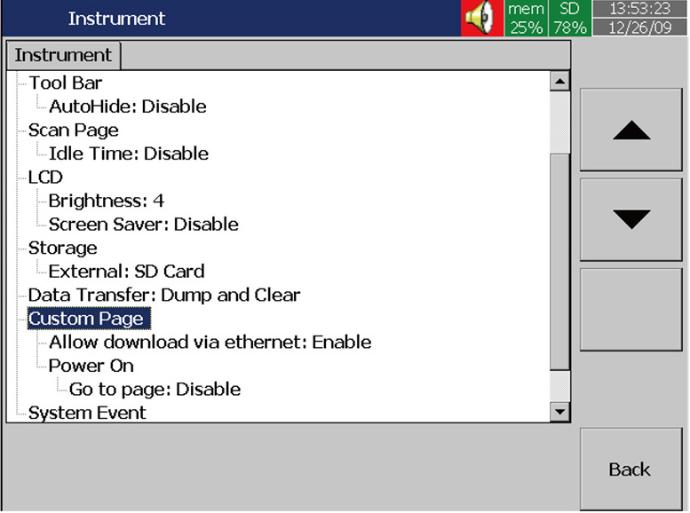

BC-SET Pro is the official configuration software for BrainChild’s Core Series temperature controllers. With a user-friendly interface, it allows engineers and technicians to configure parameters, copy settings between devices, and perform firmware upgrades via USB connection. The software supports offline setup and can store multiple configuration files, making it ideal for OEM production lines, system integrators, and field engineers.

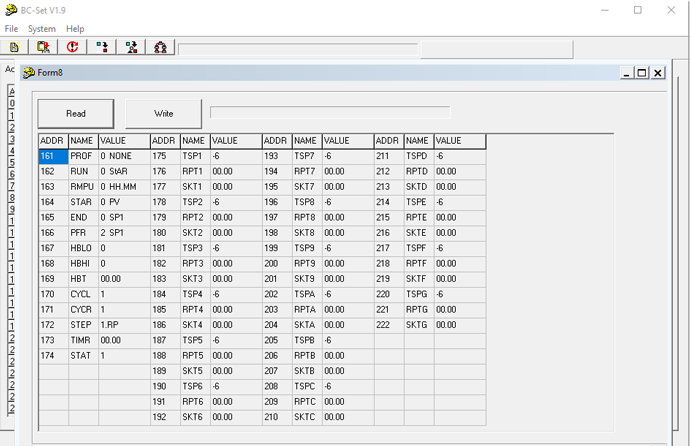

Batch Read/Write for Multiple Controllers

BC-SET allows users to connect multiple controllers of the same model and perform batch parameter read/write by defining a node address range. This feature significantly streamlines configuration in OEM or multi-device environments.

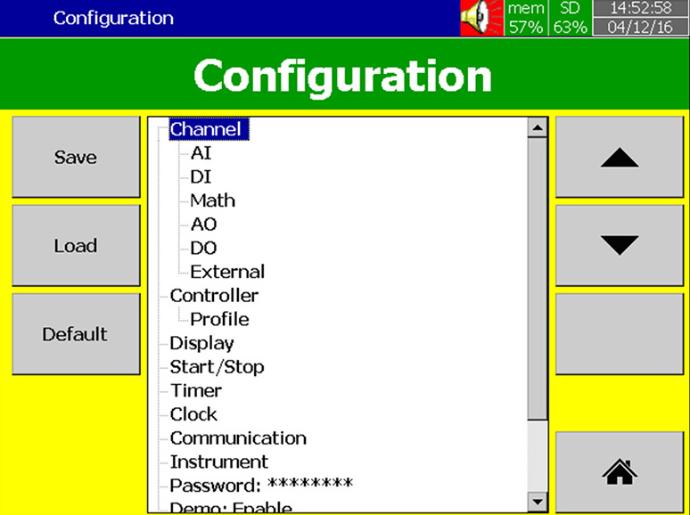

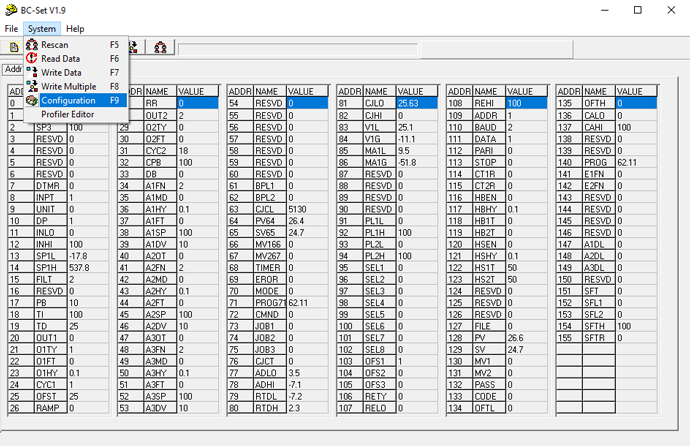

Clear and Accessible System Menu

The system menu offers quick access to key operations like Rescan (F5), Read Data (F6), Write Data (F7), Write Multiple (F8), and Communication Settings (F9). Built-in hotkeys support fast, efficient navigation.

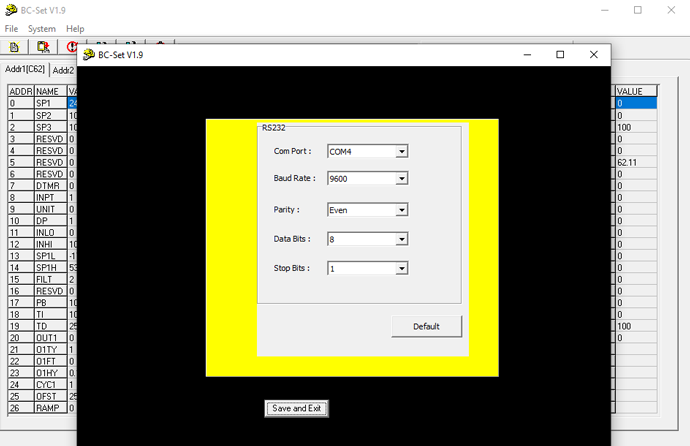

Intuitive Communication Setup Interface

The communication settings window lets users define COM port, baud rate, parity, data bits, and stop bits — with a “Default” button for quick reset and “Save and Exit” to finalize setup. Designed to reduce setup errors.

Visual Profile Editor for Programmable Controllers

For controllers with profile functionality, BC-SET provides a graphical editor to configure temperature ramp/soak segments. Users can easily read, modify, and write profile parameters for precise thermal process control.

Applications

Specification

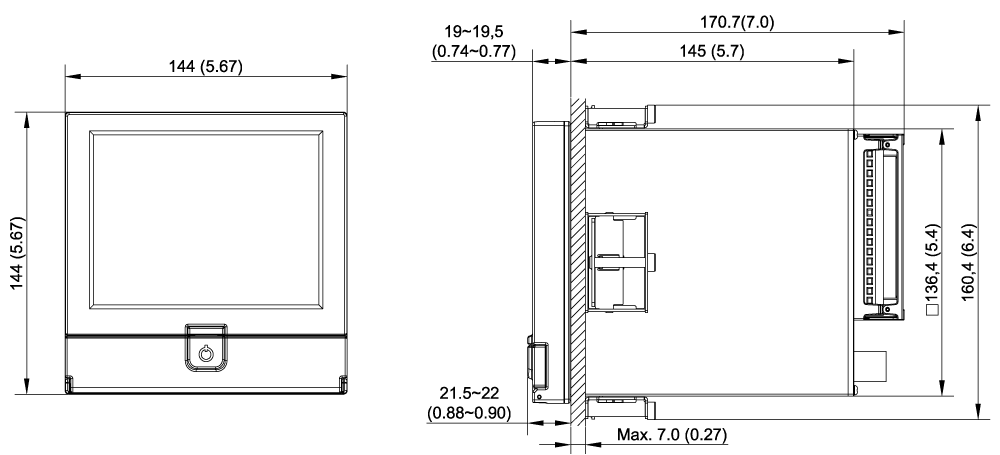

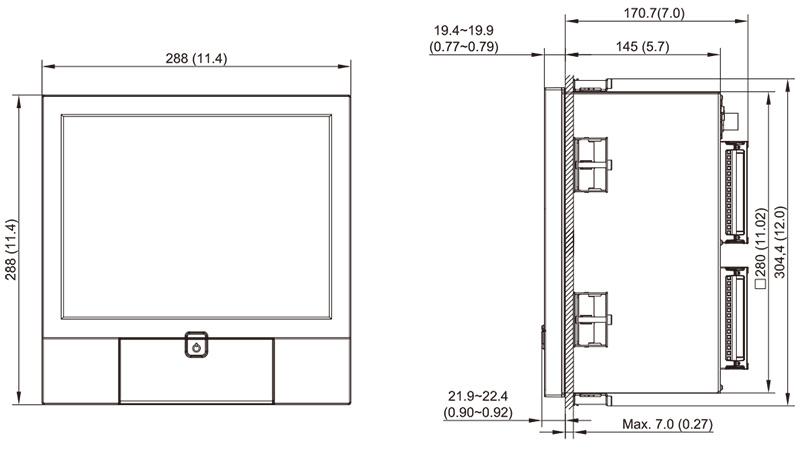

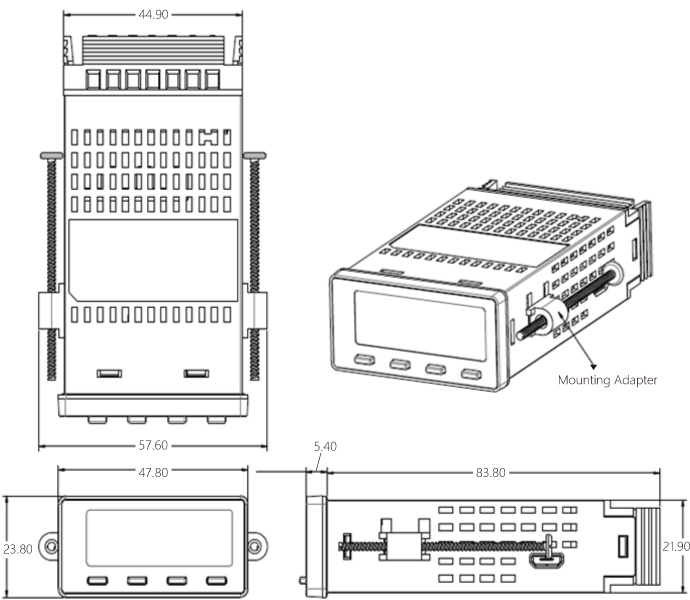

Dimensions with clamp

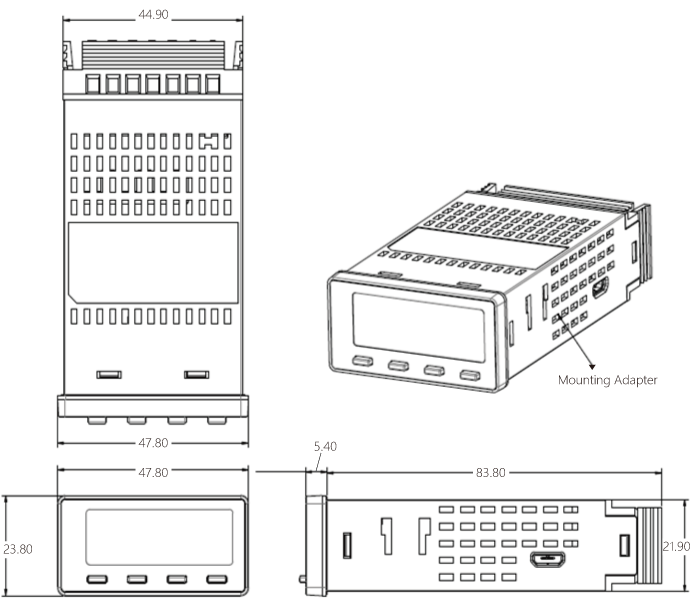

Dimension without Clamp

Power

Signal Input

Remote Set Point Input

Event Input

CT Input

Output 1 / Output 2

Alarm

Data Communication

Analog Retransmission

User Interface

Programming Port

Control Mode

Digital Filter

Profiler

Environmental and Physical Specifications

Approval Standards

Download

Visit Download Center to See More Documents & Tools of This Product. Visit

FAQ

Yes. RS-485 communication with Modbus RTU protocol is available as an optional module, allowing easy integration with PLCs and SCADA systems.

The C22 supports thermocouples (J, K, T, E, etc.), RTDs (PT100), as well as voltage (0–10V) and current (4–20 mA) signal inputs.

C22 can be configured via the front panel or by using the BC-SET Pro software through its built-in USB programming port.

Yes. The C22 automatically detects sensor failure and displays an error code, helping ensure safety and quick troubleshooting.

Absolutely. With a front panel size of just 48×24 mm, the C22 is ideal for small control panels and OEM applications.