Features

- 18-bit A/D and 15-bit D/A conversion

- Max 3 alarm outputs, multi-mode types

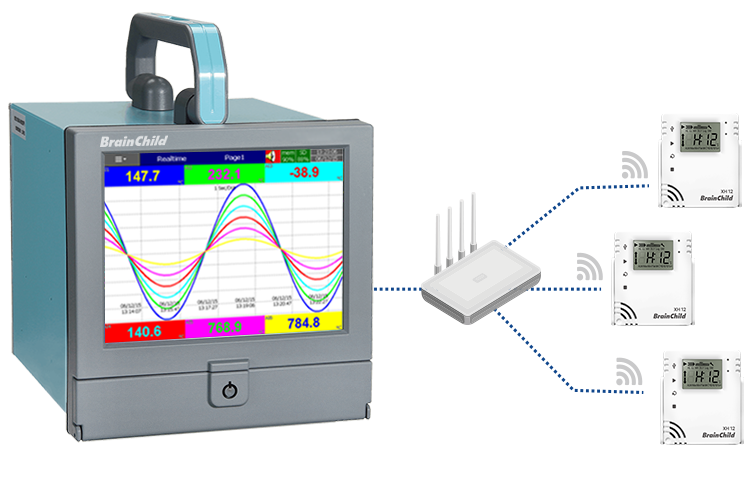

- RS-485 Modbus RTU communication

- Event input support with remote reset

- Panel mounting for industrial panels

- Analog retransmission (mA/V) optional

- Multi-level parameter protection

- Selectable °C / °F display units

- Dual display: process + setpoint

- User-defined menu shortcuts (SEL)

- Sensor break and A/D failure detection

- CE, UL, FM, RoHS, and REACH certifie

- Output failure transfer and latch logic

- Menu lock with password and security code

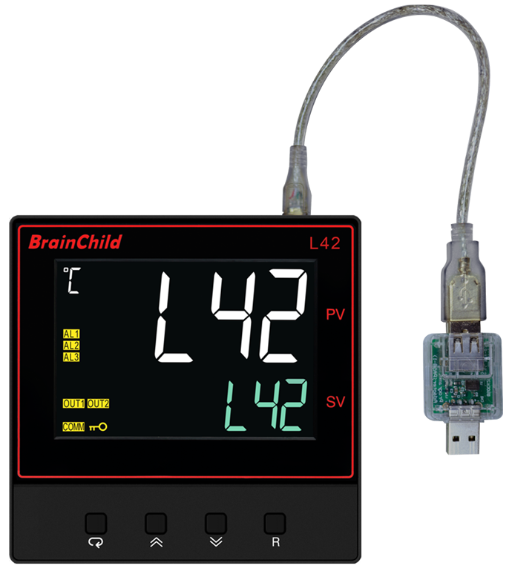

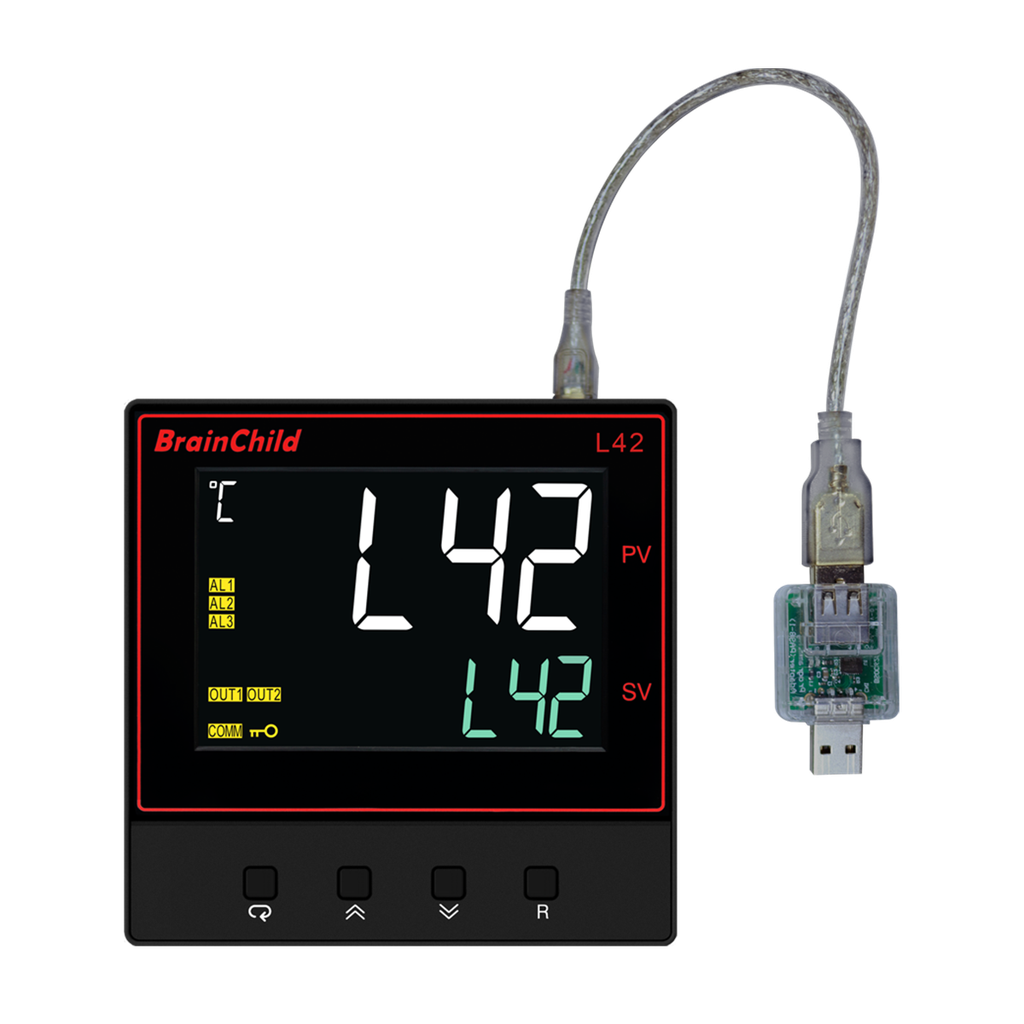

L42 Limit Controller

Built for Safety

Fast, scalable, and versatile for industrial safety

The L42 limit controller is an advanced panel-mount safety solution engineered for high-speed, precision-critical process control. With a universal input that supports a wide range of thermocouple, RTD, and analog signals, L42 adapts to nearly any sensor configuration used in temperature, pressure, or flow monitoring applications. Its dual-line LCD provides clear process value and setpoint visibility, while its intuitive menu system simplifies setup and operation for operators and integrators alike.

Designed to meet the rigorous demands of OEM and industrial automation systems, the L42 offers dual configurable outputs, support for up to three alarms, and optional analog retransmission for external recording or PLC integration. The controller also features event input for remote reset or lockout, enhancing operational safety. With built-in RS-485 communication and Modbus RTU support, it seamlessly connects to SCADA or DCS systems. Its compact and rugged panel-mount form factor ensures long-term durability and easy installation in crowded control environments.

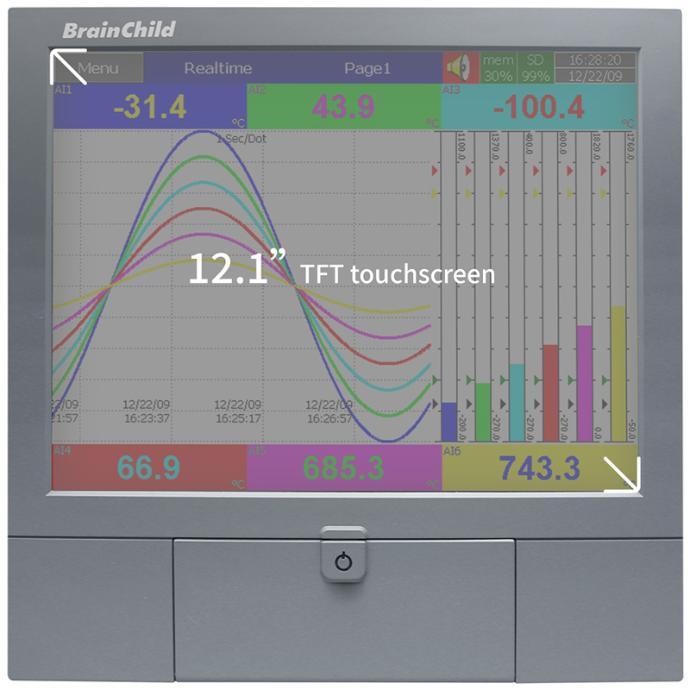

Clear Interface, Reliable Display

Dual display and LED indicators simplify operation

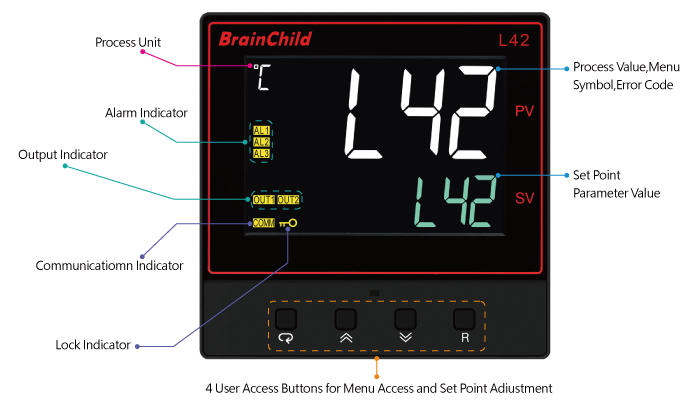

The front panel of the L42 features a high-contrast LCD display that clearly presents critical process information at a glance. The dual-line display layout separates the upper and lower screens—where the upper display shows the current process value (PV), alarm codes, or menu options, and the lower display indicates the setpoint (SP), parameter values, or navigation prompts. Four tactile and responsive membrane keys enable smooth access to menu navigation, parameter configuration, and fast setpoint adjustments without requiring complex keystrokes.

In addition to the main display, the front panel includes dedicated LED indicators to show output activation (OUT1/OUT2), unit of measurement (°C or °F), alarm status, and keypad lock status. This visual feedback helps operators confirm controller state in real time. The intuitive layout ensures user-friendly operation, even in dimly lit environments or on crowded industrial panels, reducing operational errors and enhancing safety during configuration or maintenance procedures.

Universal Sensor Input Compatibility

Supports TC, RTD, linear mV, mA, and V signals

L42 accepts a wide range of industrial signal types including thermocouples (J, K, T, E, B, R, S, N, L, U, P, C, D), RTDs such as PT100 (DIN and JIS), and linear analog inputs like 0–60 mV, 0–20 mA, and 0–10 V. Each input type can be configured via keypad or software to accommodate specific sensor requirements. With 18-bit A/D resolution, the controller ensures precise signal interpretation and fast reaction to process variations. This makes the L42 ideal for multi-zone systems or installations requiring high accuracy, fast feedback, and flexible signal handling across temperature, flow, or pressure applications.

Flexible Output to Match Your Application

Relay, SSR, or analog output with alarm modes

L42 features two standard output channels that can be configured as Form A relay contacts or solid-state relay (SSR) drivers. Both 5V and 14V SSR drive voltages are supported, depending on your output requirements. In addition to Output 1 and Output 2, a third output is optionally available for additional alarms. You can choose from multiple alarm functions, including High, Low, Deviation, Latching, or Normal. Output functions are customizable via keypad or software, and are suitable for driving alarms, interlocks, or shutdown mechanisms. Optional analog retransmission (0–10 V or 4–20 mA) provides real-time process value feedback for external monitoring or PLC integration.

Easy Offline Setup via USB

Micro USB for configuration and calibration

The L42 includes a Micro USB programming port conveniently located on the front panel, designed for offline configuration and testing. When used with BrainChild’s BC-SET Pro software and the optional CC98-1 programming cable and PA98-1 adapter, the controller can be quickly configured, cloned, or calibrated without accessing internal terminals. This port also supports automatic testing (ATE integration), making it ideal for OEM production lines and system integrators who require fast setup and parameter duplication across multiple units. Note: the programming port should only be used when the controller is powered but not in active process operation.

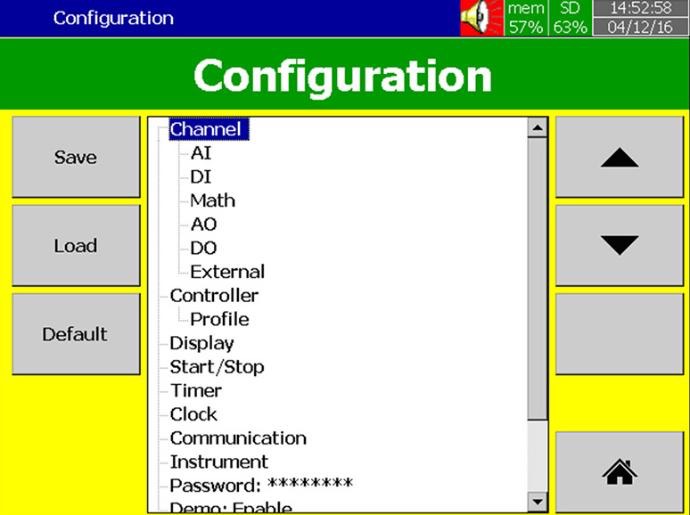

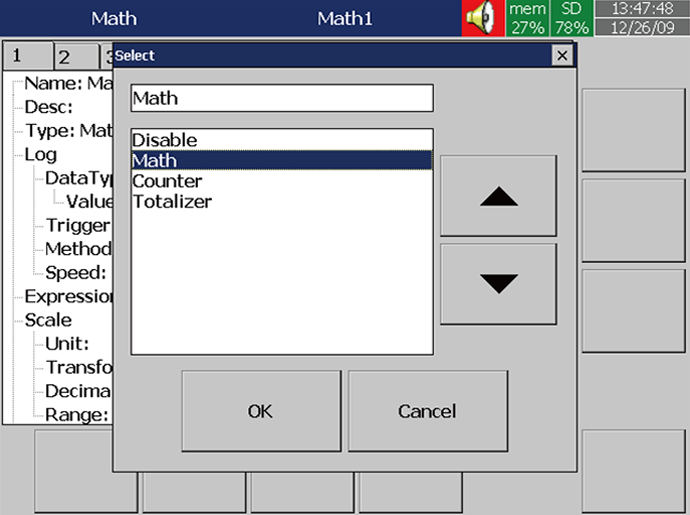

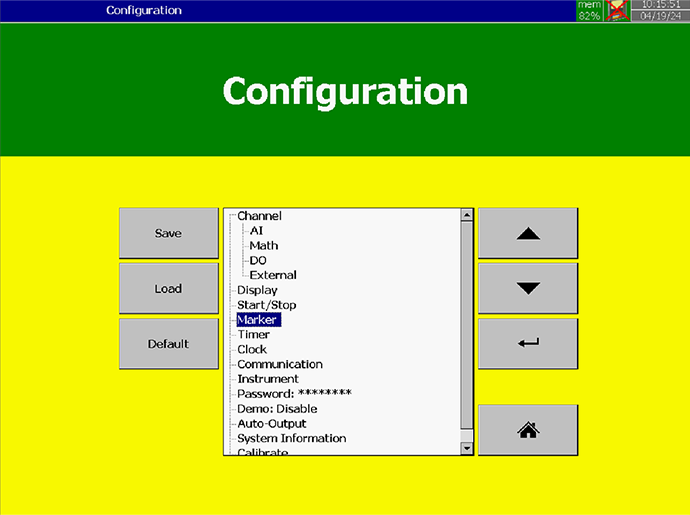

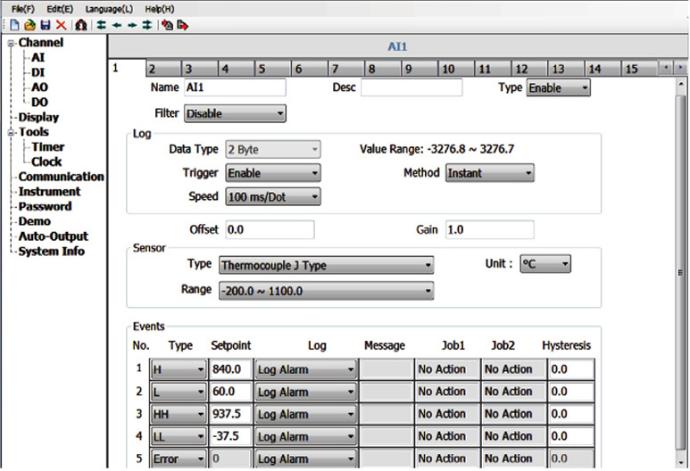

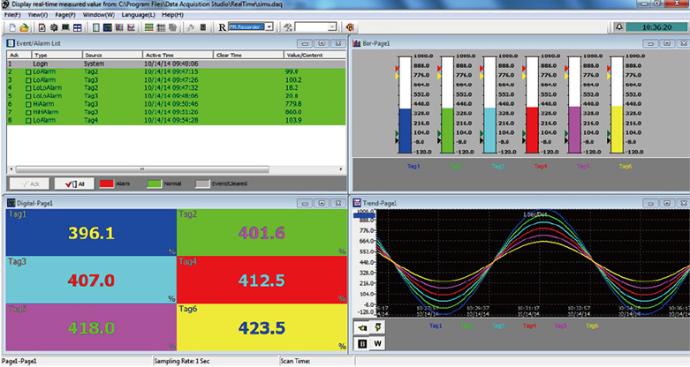

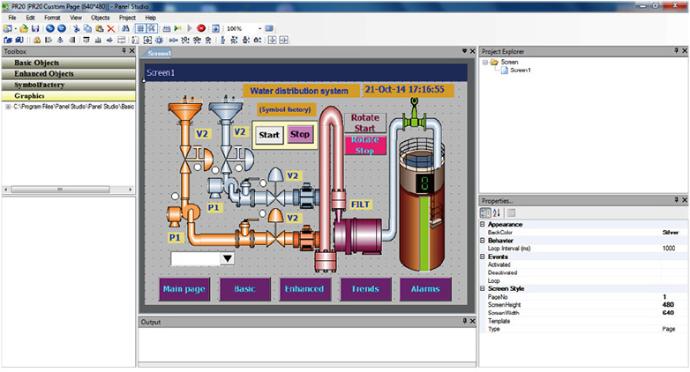

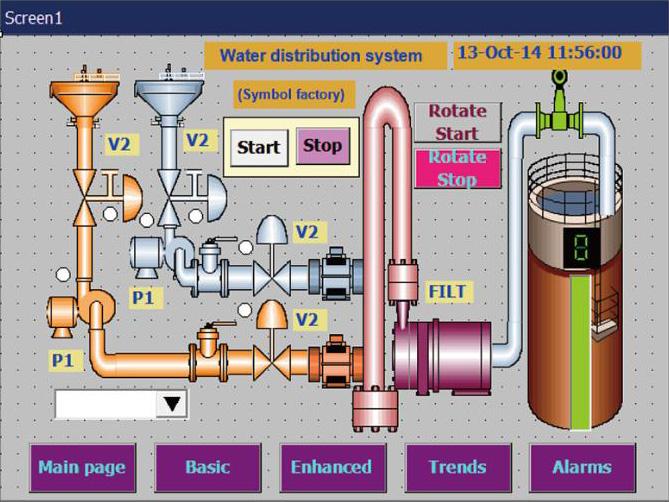

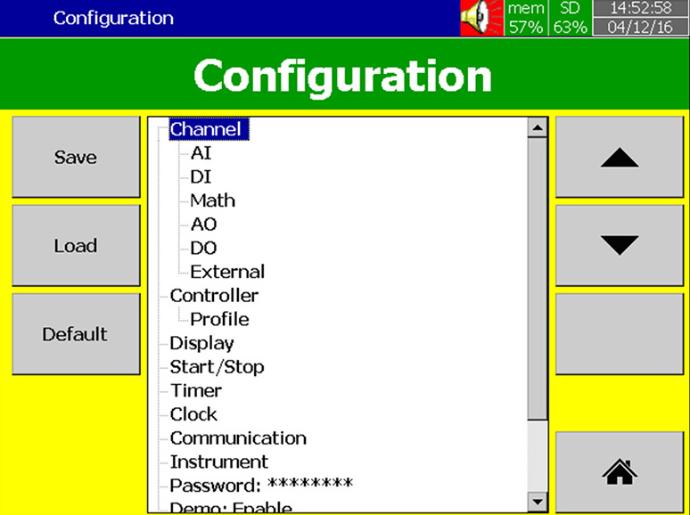

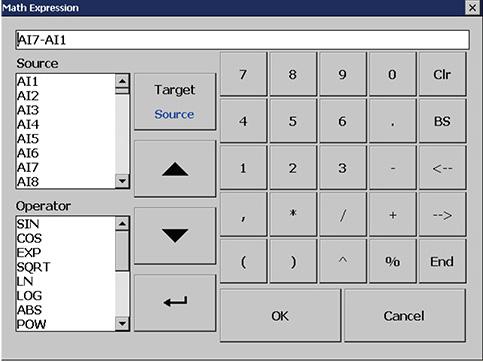

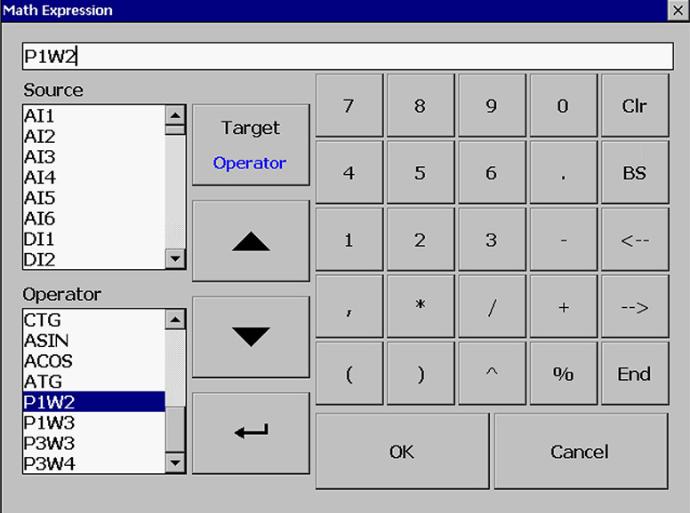

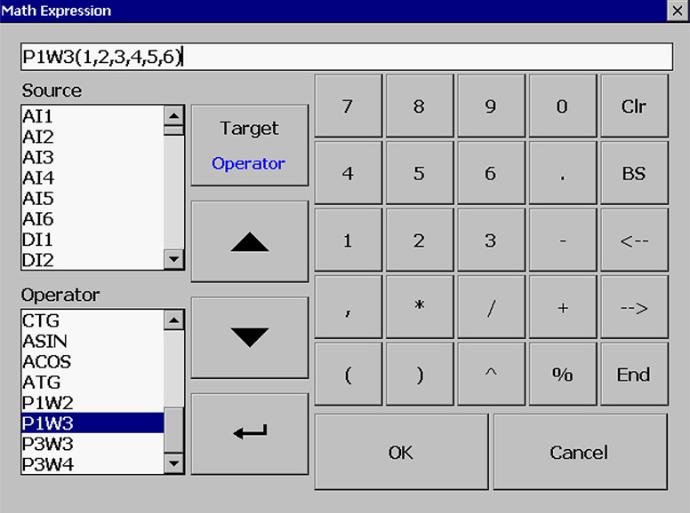

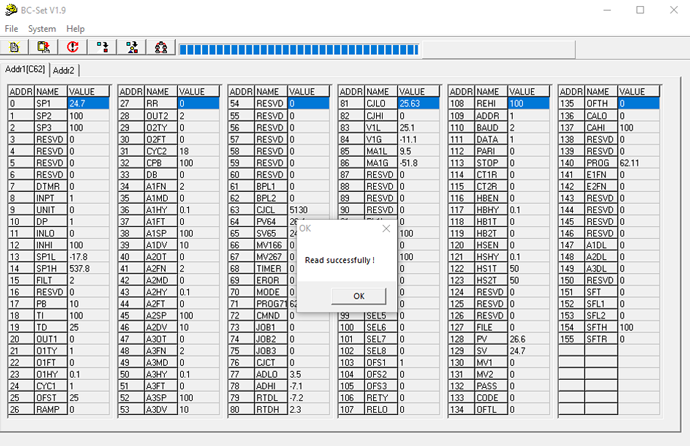

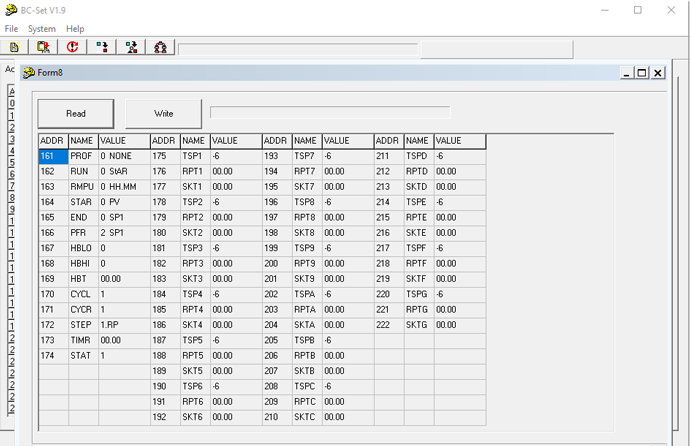

BC-SET Pro Configuration Software

Easy parameter setup, backup and firmware upgrade

BC-SET Pro is the official configuration software developed by BrainChild for its over-temperature protection controllers. With a streamlined and intuitive interface, the software allows users to connect via USB programming cable and quickly configure control parameters. It supports efficient parameter editing, setting duplication between devices, and firmware upgrades to maintain device performance and stability. BC-SET Pro also enables offline configuration with the ability to save and manage multiple profiles, making it ideal for production environments, system deployment, and ongoing maintenance. Whether for new setup or existing system adjustment, this tool helps engineers and technicians simplify workflow, reduce setup time, and ensure consistent configuration across all devices.

Batch Read/Write for Multiple Controllers

BC-SET allows users to connect multiple controllers of the same model and perform batch parameter read/write by defining a node address range. This feature significantly streamlines configuration in OEM or multi-device environments.

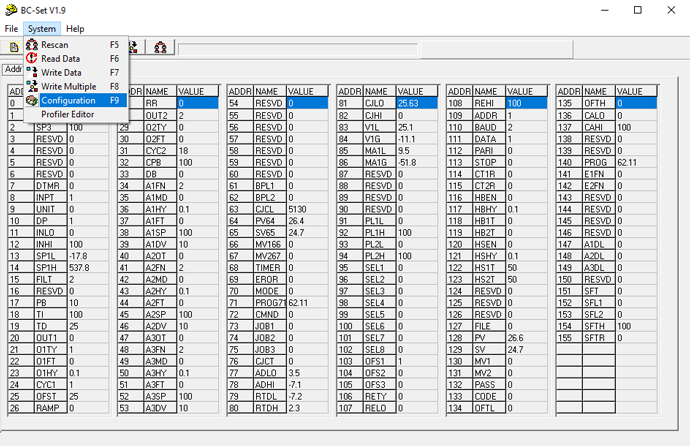

Clear and Accessible System Menu

The system menu offers quick access to key operations like Rescan (F5), Read Data (F6), Write Data (F7), Write Multiple (F8), and Communication Settings (F9). Built-in hotkeys support fast, efficient navigation.

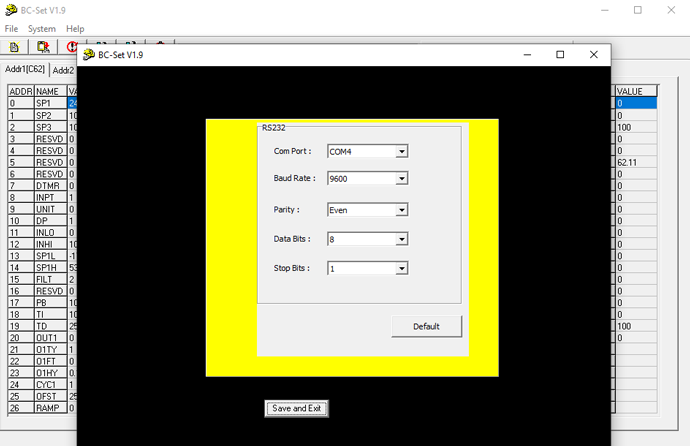

Intuitive Communication Setup Interface

The communication settings window lets users define COM port, baud rate, parity, data bits, and stop bits — with a “Default” button for quick reset and “Save and Exit” to finalize setup. Designed to reduce setup errors.

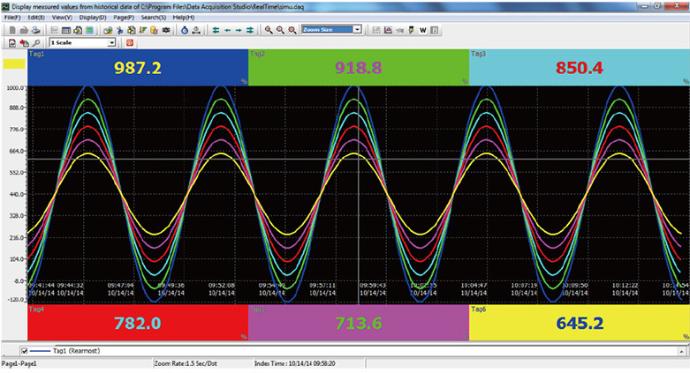

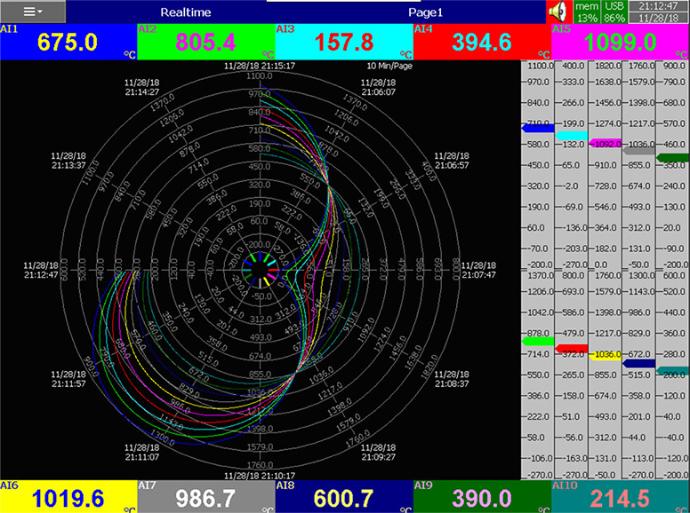

Visual Profile Editor for Programmable Controllers

For controllers with profile functionality, BC-SET provides a graphical editor to configure temperature ramp/soak segments. Users can easily read, modify, and write profile parameters for precise thermal process control.

Applications

Specification

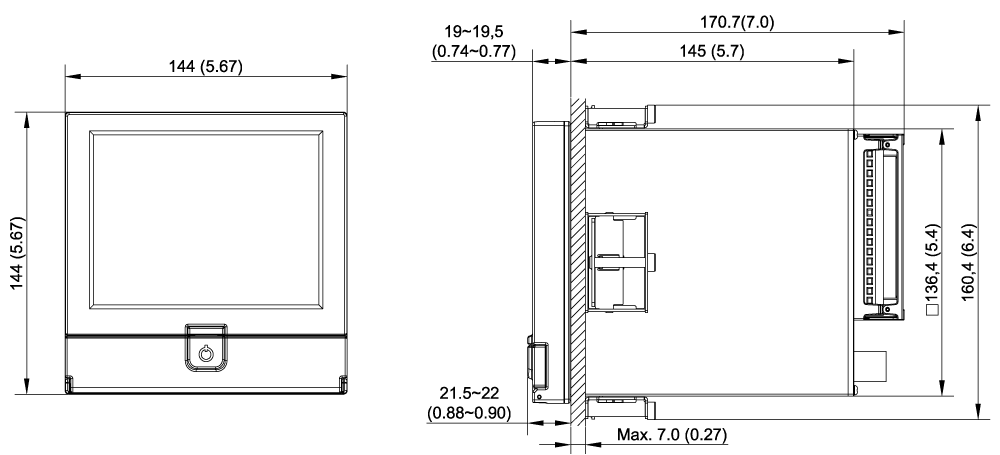

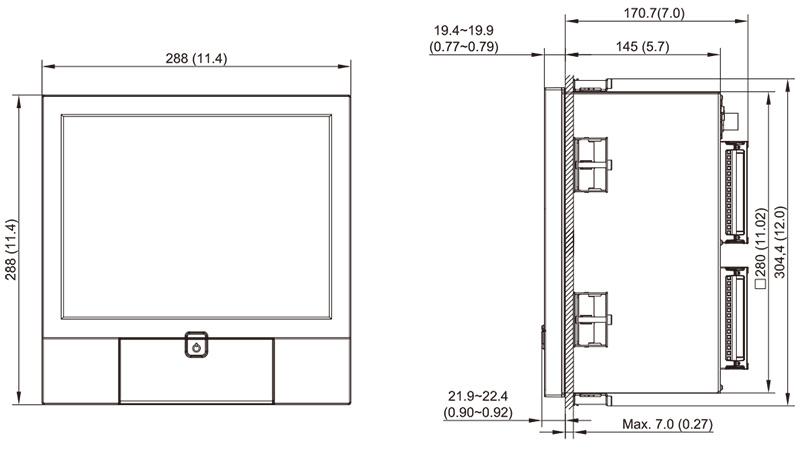

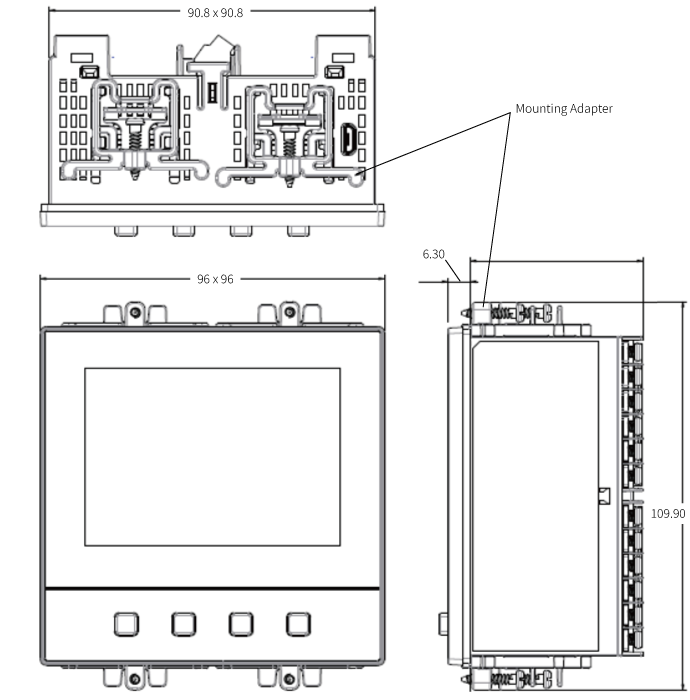

Dimension with Clamps

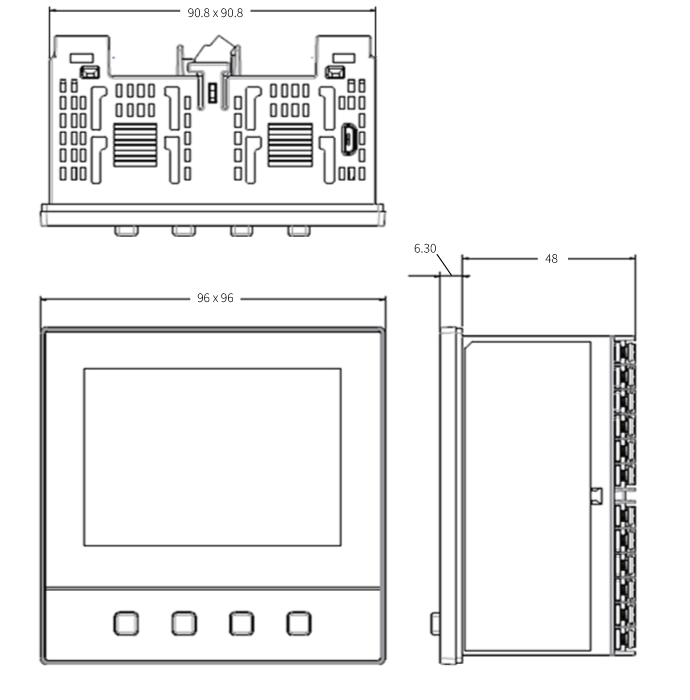

Dimension without Clamp

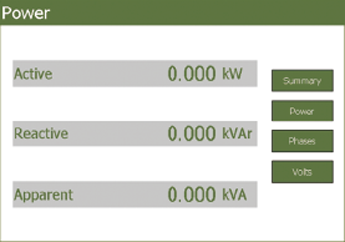

Power

Signal Input

Digital Filter

Event Input

Output 1 / Output 2

Alarm

Data Communication

Analog Retransmission

User Interface

Environmental and Physical Specifications

Approval Standards

Download

Visit Download Center to See More Documents & Tools of This Product. Visit

FAQ

The L42 is designed for panel-mounted over-temperature protection and process limit monitoring. It detects when process values exceed preset limits and triggers outputs to ensure system safety.

L42 supports thermocouples (J, K, T, E, B, etc.), RTDs (PT100 DIN/JIS), and analog signals including 0–60mV, 0–20mA, and 0–10V. Input configuration can be set via the keypad or PC software.

L42 includes two configurable outputs (relay or SSR drive), with an optional third alarm output. Analog retransmission (4–20mA or 0–10V) is also available for external monitoring or PLC connection.

Yes. The L42 features a Micro USB programming port for offline configuration, firmware updates, and parameter cloning using BrainChild’s BC-SET Pro software and accessories.

The L42 offers IP50 protection on the front panel and IP20 on the terminal section. It is certified by FM, UL, CSA, and meets EN61010-1 and RoHS standards for industrial panel installations.

Catalog_L22 & L42 & L62_

Catalog_L22 & L42 & L62_ Software_BC-Set_2.0

Software_BC-Set_2.0