Features

- Universal input with wide sensor range

- 18-bit A/D converter ensures accuracy

- Dual output for limit and alarm functions

- Relay or solid-state output selectable

- Optional analog retransmission (mA/V)

- RS-485 Modbus RTU slave mode

- Up to 3 alarm output configuration

- 2 event input ports (option)

- Programmable SEL quick menu access

- Lockout and remote reset supported

- 4-button keypad for intuitive control

- LCD dual display for PV and SP values

- LED indicators for output status

- CE, UL, FM approved with RoHS compliance

- Front panel IP50 protection

L62 Limit Controller

Safety Precision Built In

Enhancing industrial safety with advanced limit control

The L62 Limit Controller from BrainChild delivers fast, stable, and precise limit protection in space-limited industrial applications. Its compact 1/16 DIN design integrates universal sensor input, dual outputs (relay or SSR), fast 200ms sampling, and RS-485 Modbus communication for remote integration. It offers flexible alarm logic, event inputs, analog retransmission, and an optional third output channel, making it ideal for over-temperature protection in heating systems or control cabinets. With a dual-line LCD, Micro USB setup port, and BC-SET Pro support, the L62 simplifies both configuration and firmware updates. Robust front-panel operation and flexible output logic make it suitable for OEM integration or on-site safety upgrades.

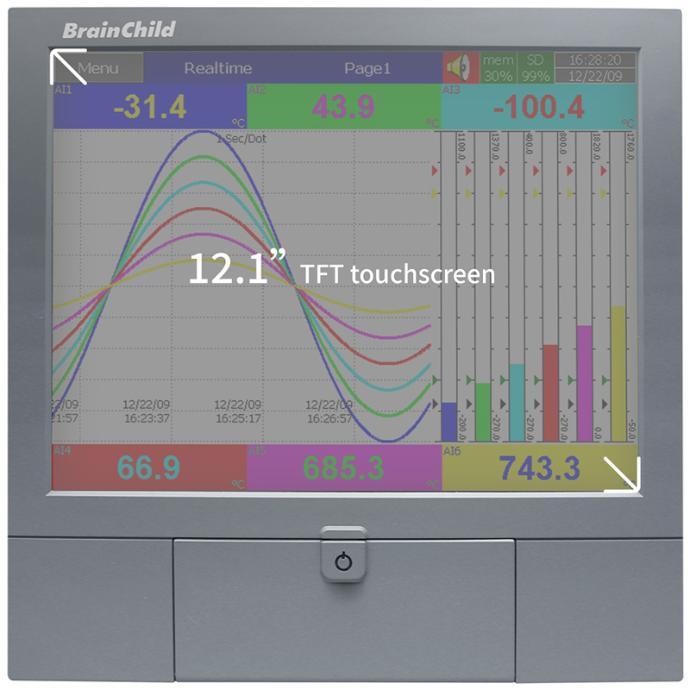

Intuitive Dual Display with 4-Key Control

Simplify setup and monitoring on-site with ease

L62 features a high-visibility dual-line LCD: the upper line shows the process value (PV), unit, menu code, or error messages, while the lower line displays setpoint (SP) or parameter data. Dedicated output and lock status indicators help users instantly confirm system status. The membrane keypad includes 4 responsive buttons that enable fast access to menus, parameter editing, and alarm resets. The clean interface is optimized for OEMs and operators needing quick verification and minimal training.

Multi-Sensor Input with High Precision

Supports TC, RTD, mV, V, and mA signals

L62 supports multiple sensor inputs including thermocouples (J, K, T, E, B, R, S, N, L, P, C), RTD (PT100 DIN/JIS), mV (0–60mV), current (0–20mA), and voltage (0–1V, 0–10V). All types are selectable via keypad or software. An integrated 18-bit A/D converter ensures fast and accurate conversion. The unit auto-compensates for sensor differences, making it suitable for heat treatment, oven, or safety-critical system monitoring.

Dual Output with Alarm Logic Options

Relay or SSR drive with 3rd output available

Output 1 and Output 2 can be set as relay contact (2A/240VAC) or SSR drive (5V/14V). An optional Output 3 is available for expanded alarm logic. Users can program high, low, or deviation alarms, as well as choose latching or normal reset behavior. Optional analog retransmission (4–20mA or 0–10V) provides PV feedback to recorders or PLCs. The flexible logic makes L62 suitable for shutdown, alarm, or interlock applications.

USB-Based Offline Configuration

Use BC-SET Pro software for fast setup and cloning

The L62 features a built-in Micro USB programming port on the front panel, providing engineers with a fast and convenient way to configure devices without entering menu layers manually. Using BrainChild’s BC-SET Pro software along with the CC98-1 cable and PA98-1 adapter, users can perform offline parameter setup, firmware upgrades, and device cloning with ease. This functionality is especially useful in OEM or batch deployment scenarios where consistent configuration across multiple controllers is essential. The programming port also supports ATE (Automated Test Equipment) environments, offering a standardized interface for production-line testing, calibration, or mass firmware initialization prior to delivery. Note: The port should only be used when the controller is powered and not in active process operation.

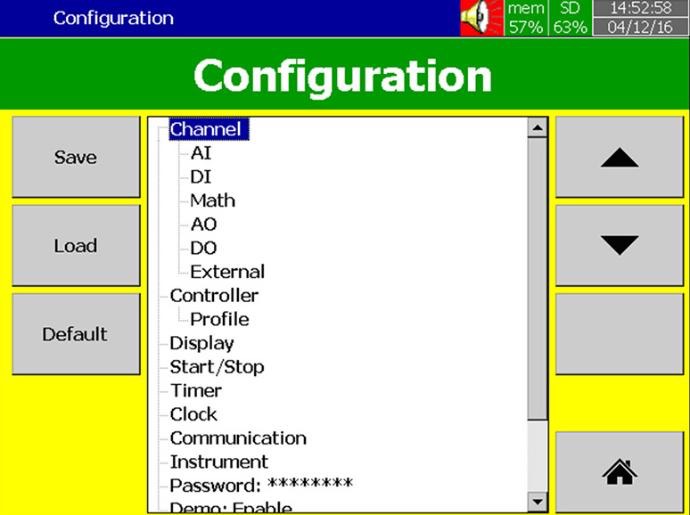

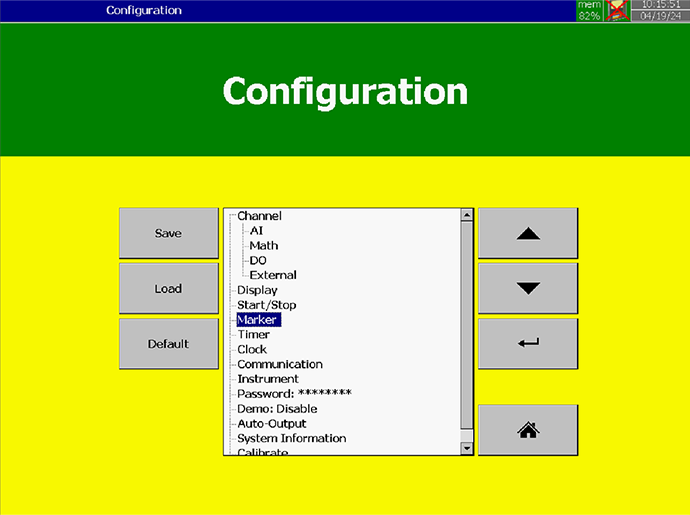

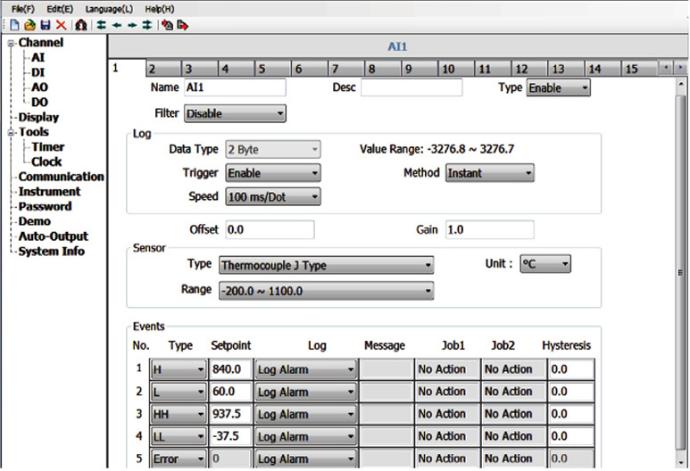

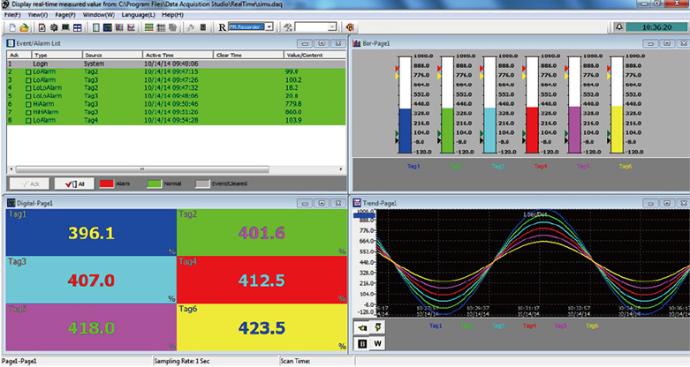

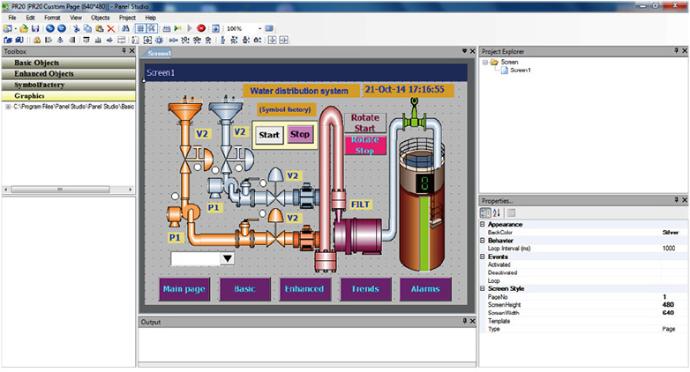

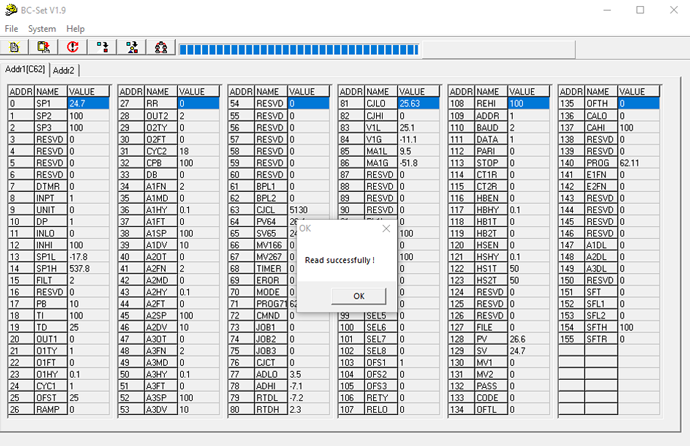

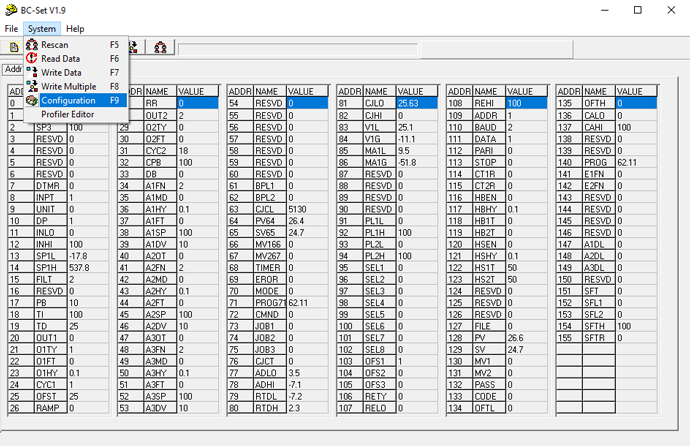

BC-SET Pro Configuration Software

Easy parameter setup, backup and firmware upgrade

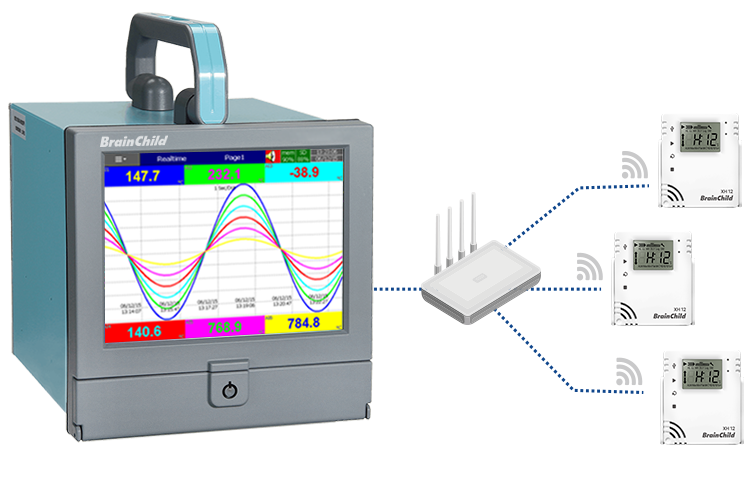

BC-SET Pro is the official configuration software developed by BrainChild for its over-temperature protection controllers. With a streamlined and intuitive interface, the software allows users to connect via USB programming cable and quickly configure control parameters. It supports efficient parameter editing, setting duplication between devices, and firmware upgrades to maintain device performance and stability. BC-SET Pro also enables offline configuration with the ability to save and manage multiple profiles, making it ideal for production environments, system deployment, and ongoing maintenance. Whether for new setup or existing system adjustment, this tool helps engineers and technicians simplify workflow, reduce setup time, and ensure consistent configuration across all devices.

Batch Read/Write for Multiple Controllers

BC-SET allows users to connect multiple controllers of the same model and perform batch parameter read/write by defining a node address range. This feature significantly streamlines configuration in OEM or multi-device environments.

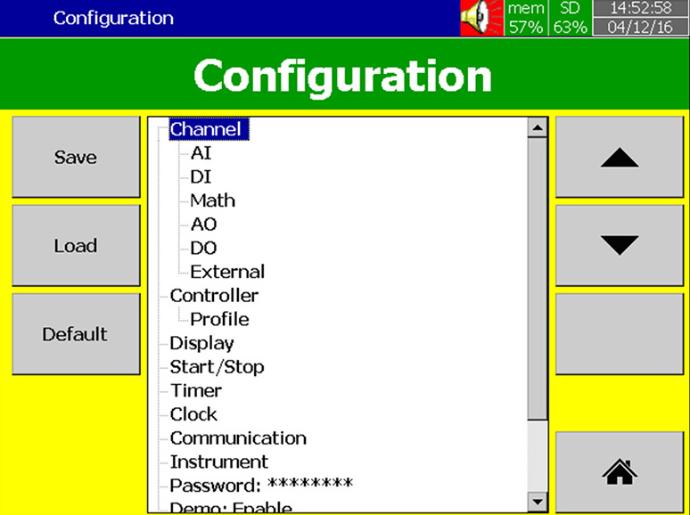

Clear and Accessible System Menu

The system menu offers quick access to key operations like Rescan (F5), Read Data (F6), Write Data (F7), Write Multiple (F8), and Communication Settings (F9). Built-in hotkeys support fast, efficient navigation.

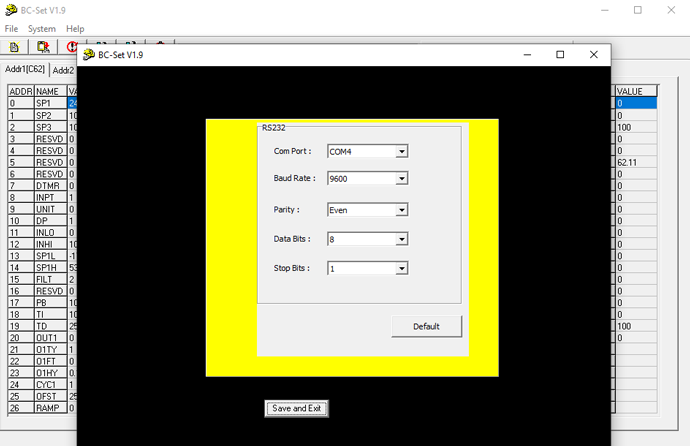

Intuitive Communication Setup Interface

The communication settings window lets users define COM port, baud rate, parity, data bits, and stop bits — with a “Default” button for quick reset and “Save and Exit” to finalize setup. Designed to reduce setup errors.

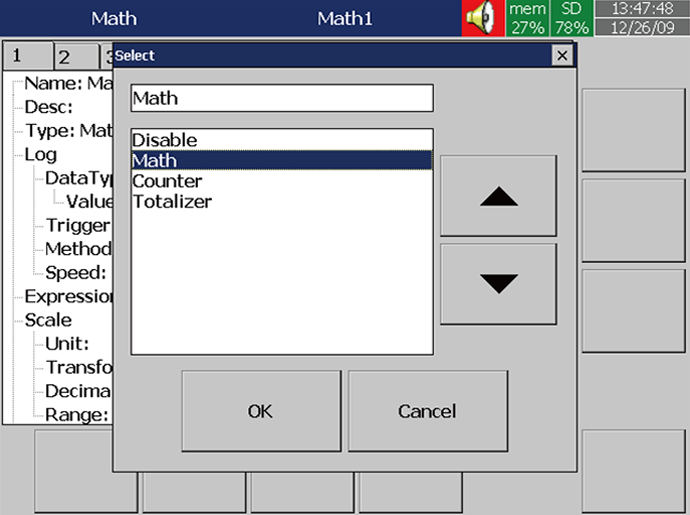

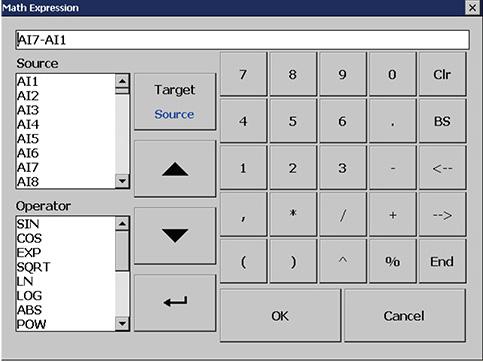

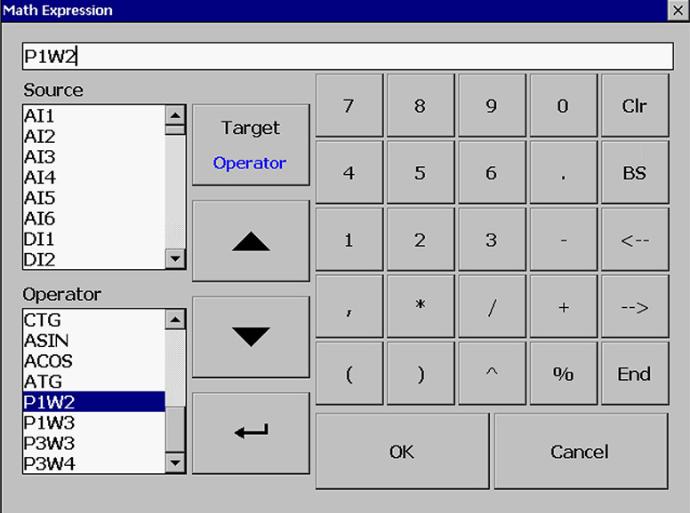

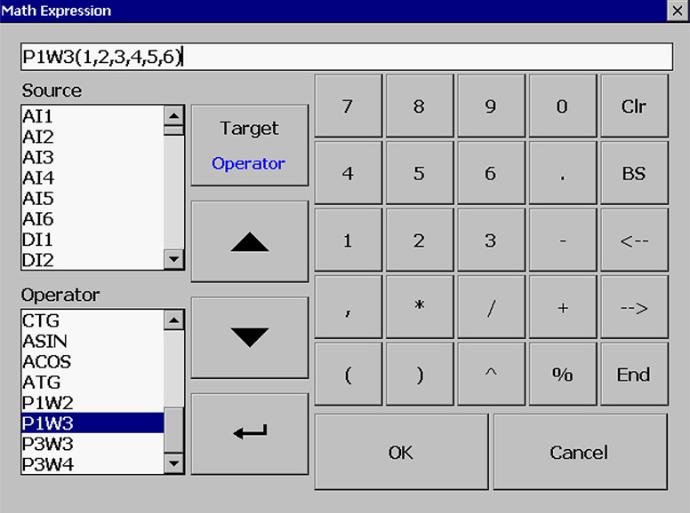

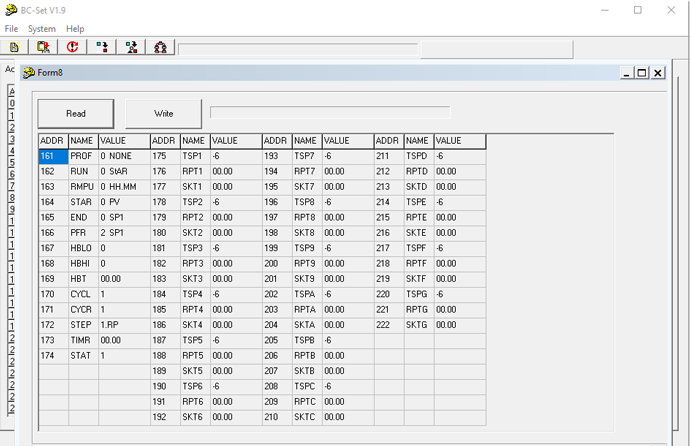

Visual Profile Editor for Programmable Controllers

For controllers with profile functionality, BC-SET provides a graphical editor to configure temperature ramp/soak segments. Users can easily read, modify, and write profile parameters for precise thermal process control.

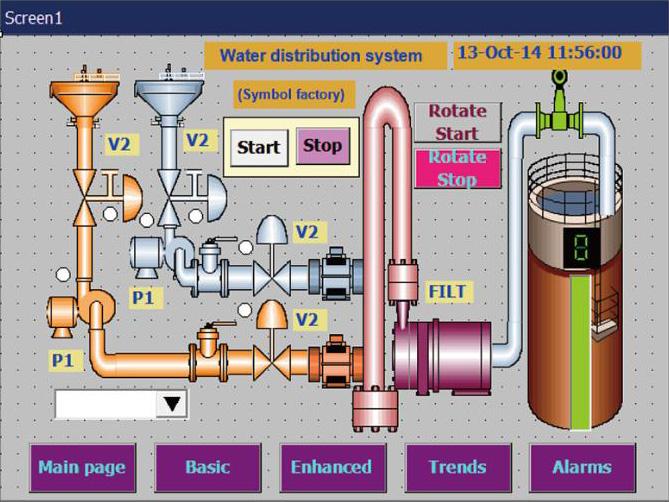

Applications

Specification

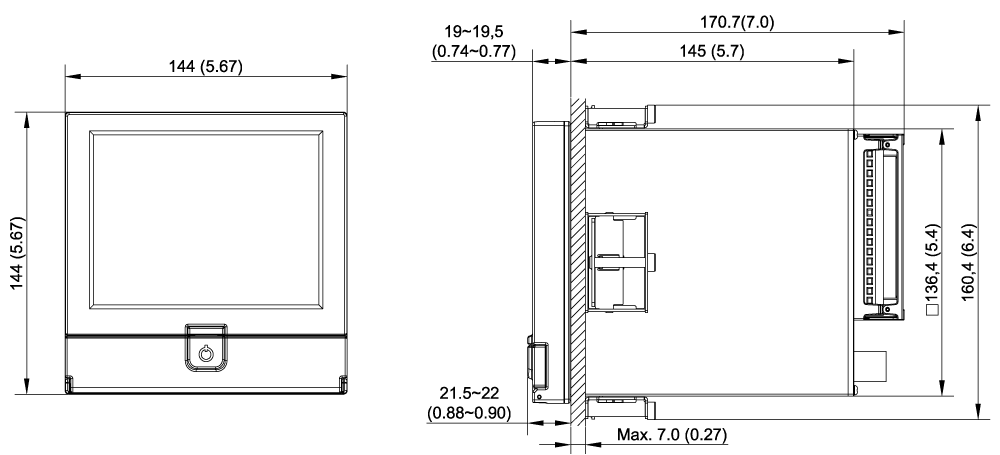

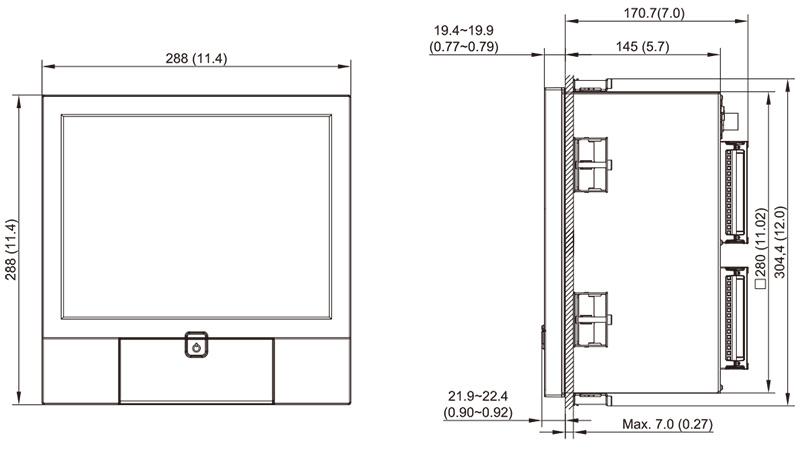

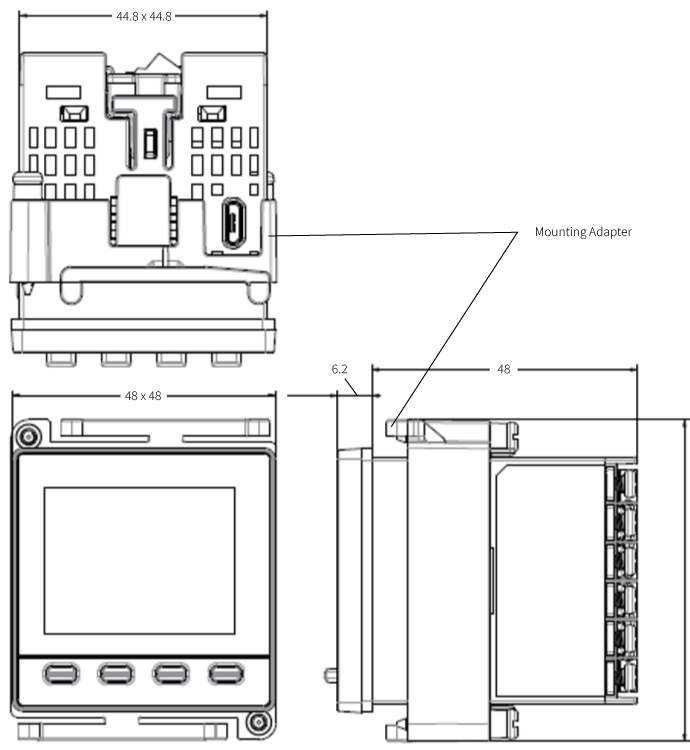

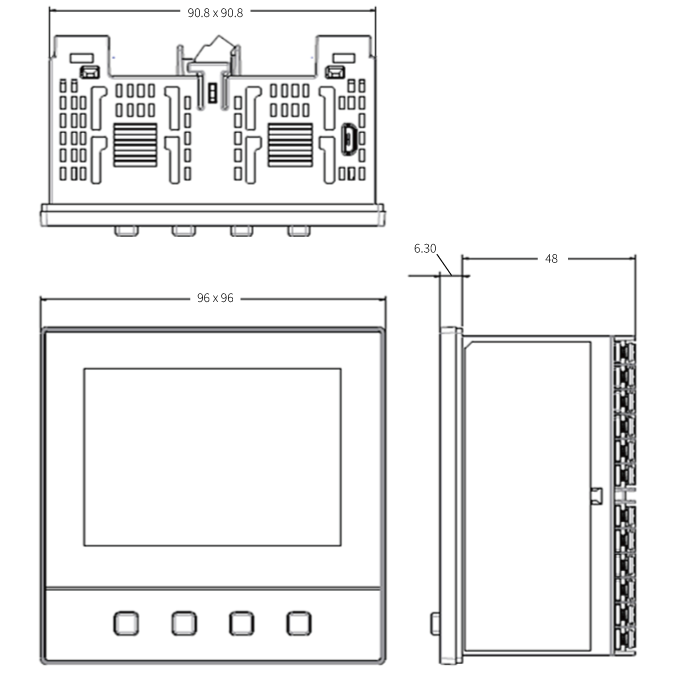

Dimension with Clamps

Dimension without Clamp

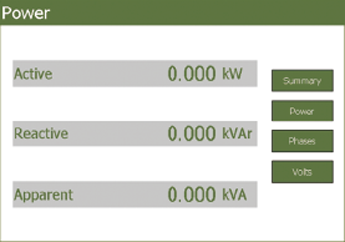

Power

Signal Input

Digital Filter

Event Input

Output 1 / Output 2

Alarm

Data Communication

Analog Retransmission

User Interface

Programming Port

Environmental and Physical Specifications

Approval Standards

Download

Visit Download Center to See More Documents & Tools of This Product. Visit

FAQ

The L62 is designed for precise over-temperature or under-temperature shutdown in industrial systems. It monitors process values and triggers output actions when preset limits are exceeded.

L62 supports thermocouples (J, K, T, etc.), RTD (PT100 DIN/JIS), and analog signals such as 0–60mV, 0–10V, and 4–20mA. Input type is selectable via keypad or PC software.

The L62 offers dual output channels configurable as Form A relay or SSR drive (5V or 14V). Optional analog retransmission is available for signal feedback to PLC or recorders.

Yes. L62 includes a Micro USB programming port. Using the CC98-1 cable and PA98-1 adapter with BC-SET Pro software, users can configure parameters, copy settings, and update firmware.

L62 offers IP50 front panel and IP20 rear housing protection. It is certified with CE, UL, FM, RoHS, and meets EN61010-1 safety and EMC standards for global use.

Catalog_L22 & L42 & L62_

Catalog_L22 & L42 & L62_ Software_BC-Set_2.0

Software_BC-Set_2.0