Features

- 9 profiles with up to 288 total segments

- Ramp, soak, jump, and end segment types

- Profile editing while process is running

- Multi-event outputs for flexible control

- Dual PID parameter sets for switching

- High-speed 5 Hz sampling for fast response

- 18-bit A/D and 15-bit D/A resolution

- 0.1°C display accuracy for TC and RTD

- Manual and auto-tuning control options

- Analog retransmission for PV or SV

- Supports relay, SSR, voltage, and current outputs

- RS-485 Modbus or RS-232 communication

- Programming port for offline parameter setup

- Bumpless transfer on sensor error

- Password lock to prevent unauthorized access

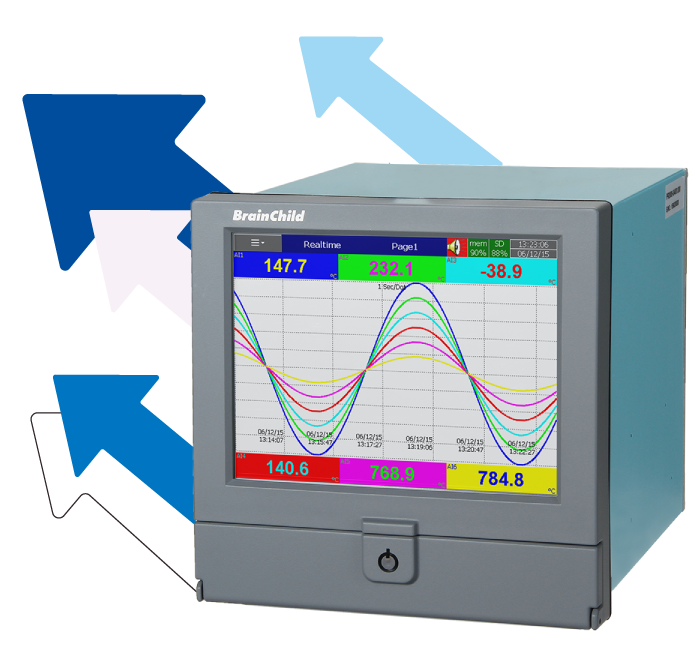

P91 Profiling Controller for Precision Process Control

Compact controller with 9 profiles and 64 segments

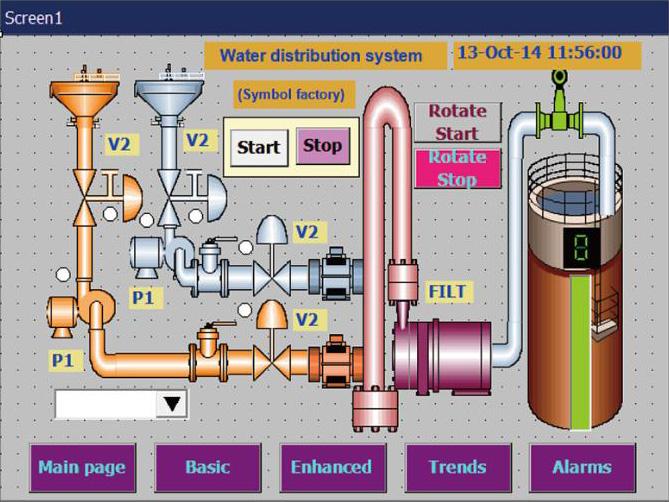

The BrainChild P91 Profiling Controller is a 1/16 DIN compact process controller designed for precise thermal control in applications requiring programmable temperature profiles. Supporting up to 9 profiles and 64 segments per program, the P91 enables ramp/soak sequencing with user-defined slope and hold parameters. With fuzzy logic-enhanced PID, it ensures quick response and stable output across a wide range of sensor inputs. Advanced features like multi-event output, RS-485 communication, analog retransmission, and profile jump control make it ideal for heating ovens, burn-in chambers, and temperature cycling systems. Its intuitive front panel and programming flexibility simplify integration for OEMs and industrial users alike.

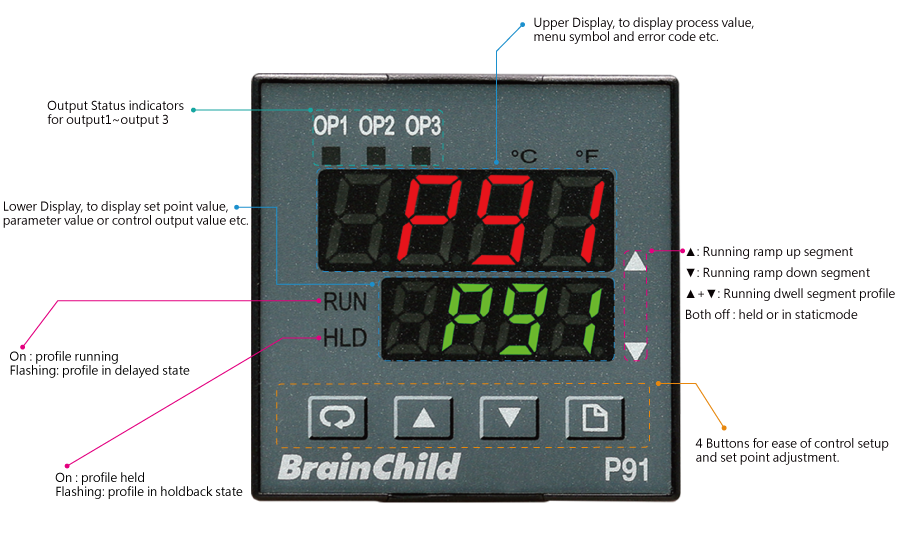

Intuitive Dual Display for Easy Monitoring

Clear PV/SV display with status indicators and soft keys

The P91 features a user-friendly dual display design: the upper window shows the current process value (PV), menu symbols, and error codes, while the lower window displays the set point (SV) or parameter values. Visual indicators for output status, alarm signals, communication activity, and lock condition help users quickly assess device status. Four intuitive buttons on the front panel enable quick navigation through menus and direct adjustment of control settings. This clear and compact interface streamlines daily operation and setup, improving efficiency for operators in production or lab environments.

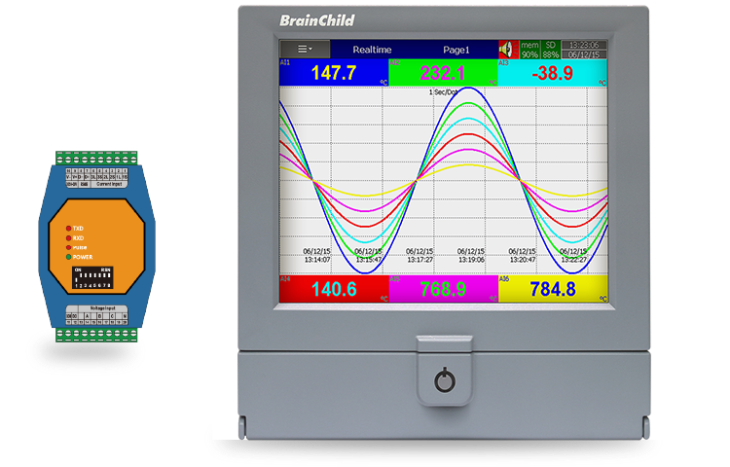

Universal Sensor Input for Process Flexibility

Supports TC, RTD, mV, V, and mA signals

P91 supports a comprehensive range of input types to meet the requirements of diverse applications. Compatible with thermocouples (J, K, T, E, B, R, S, N, L, C, P), RTDs (PT100 DIN/JIS), and analog signals (0–60 mV, 0–1 V, 0–5 V, 1–5 V, 0–10 V, 0–20 mA, 4–20 mA), the controller enables seamless switching via front panel or software. Its high-resolution A/D converter ensures accurate measurement and fast response for precise control, while flexible display settings enhance usability in industrial operations.

Multiple Output Types for Advanced Control

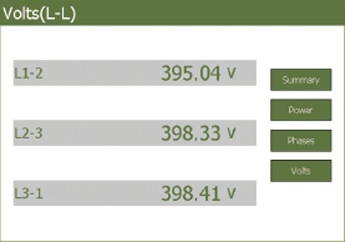

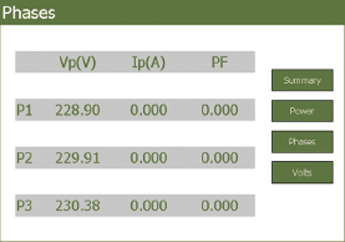

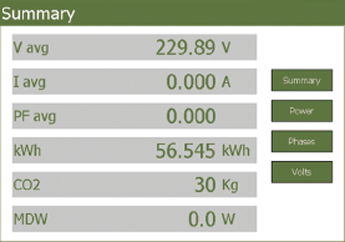

Relay, SSR, Linear Output, and RS-485 available

P91 provides flexible output configurations including relay (2A/240VAC), SSR drive (5V/30mA or 14V/40mA), linear analog output (4–20 mA / 0–10 V), and triac (1A/240VAC). It also supports optional communication and sensor power modules, such as RS-485 / RS-232 and 5V/80mA, 12V/40mA, 20V/25mA outputs. These options enable seamless integration with automation systems, external alarms, transmitters, and data acquisition units—ideal for precise profiling control in complex processes.

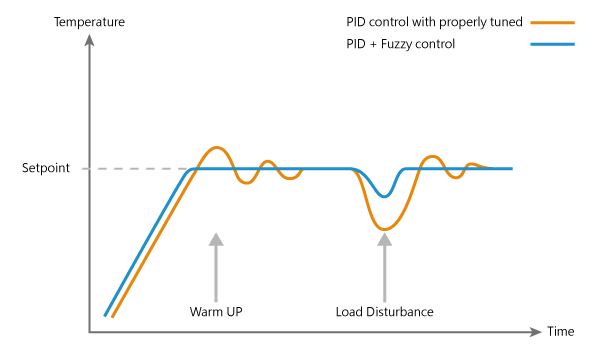

Fuzzy PID Technology

Smarter Control with Less Overshoot and Faster Response

Fuzzy logic is combined with traditional PID control to deliver smarter and more adaptive temperature regulation. Unlike standard PID controllers that require manual fine-tuning for each application, fuzzy PID dynamically adjusts control responses based on real-time process behavior. The result is faster stabilization, reduced overshoot, and improved resilience to disturbances—ideal for processes where precision and speed are critical.

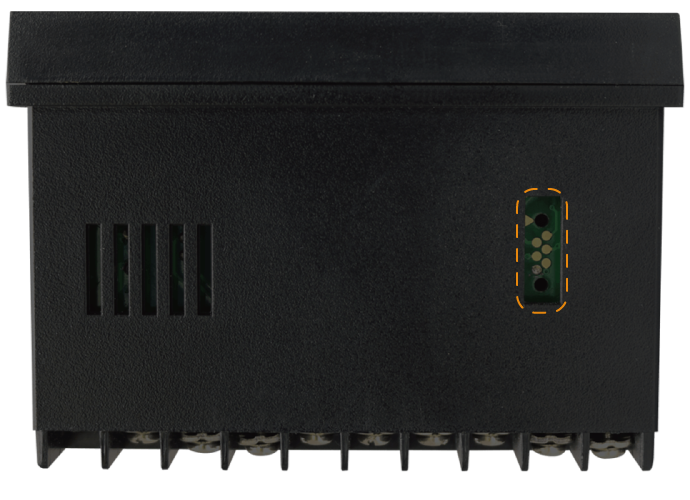

Dedicated Port for PC-Based Configuration

Supports offline setup, cloning, and calibration

The P91 includes a dedicated programming port, allowing offline parameter setup via PC or ATE system using a special USB cable. This enables quick cloning of device configurations, firmware upgrades, and auto-calibration for consistent system performance. Ideal for OEM deployment or factory testing, the interface is designed for initial setup only and not recommended for operation during run mode.

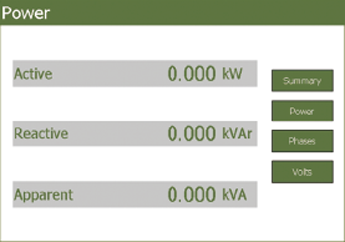

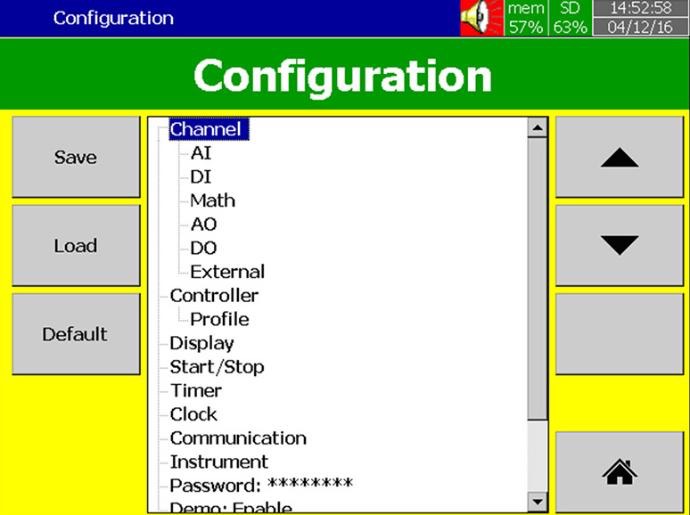

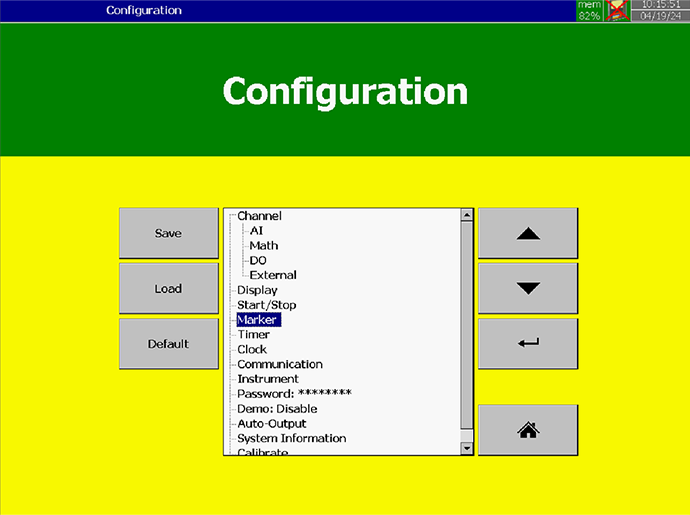

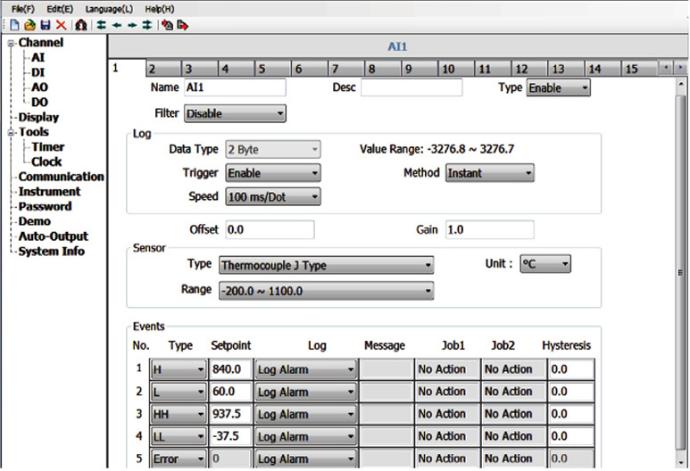

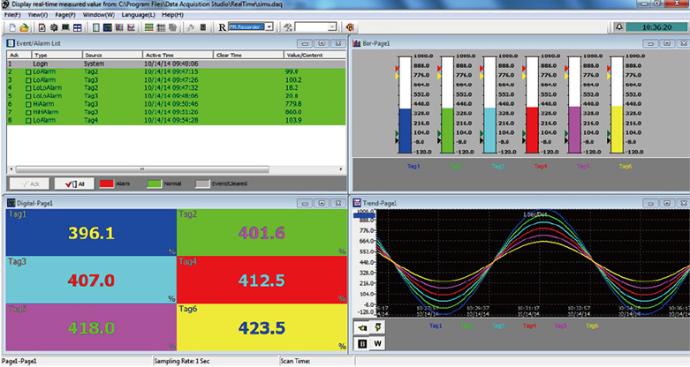

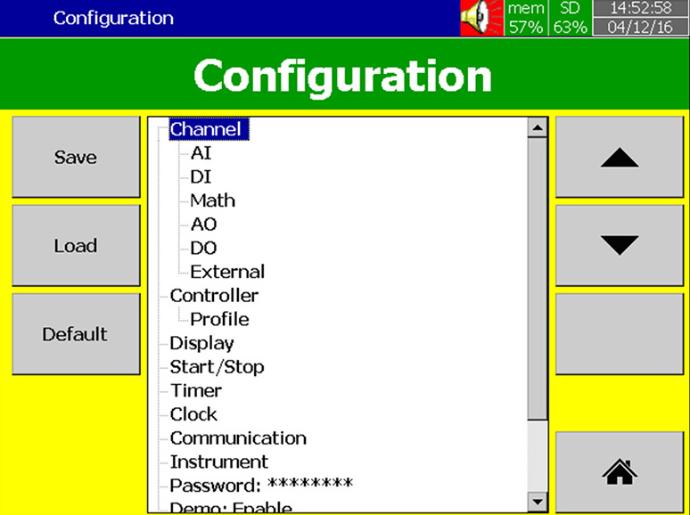

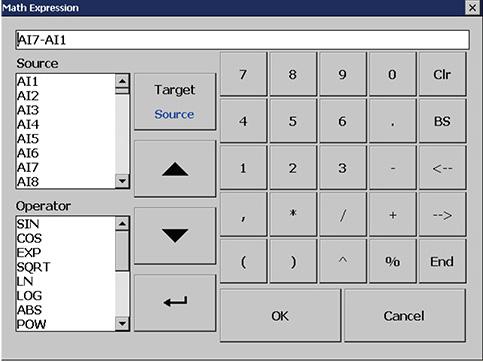

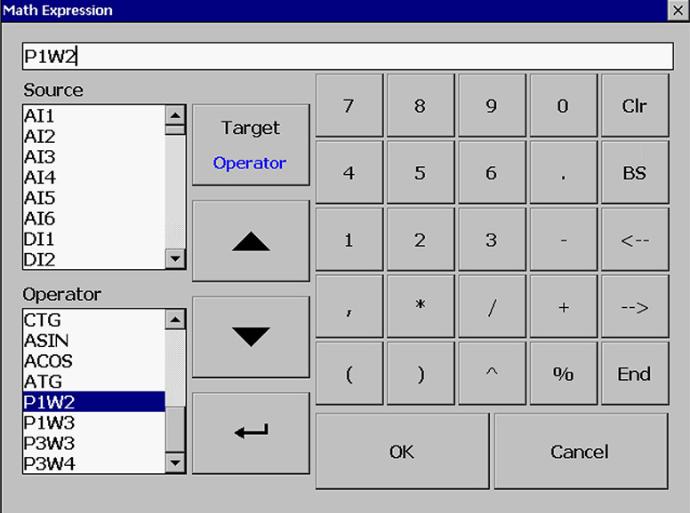

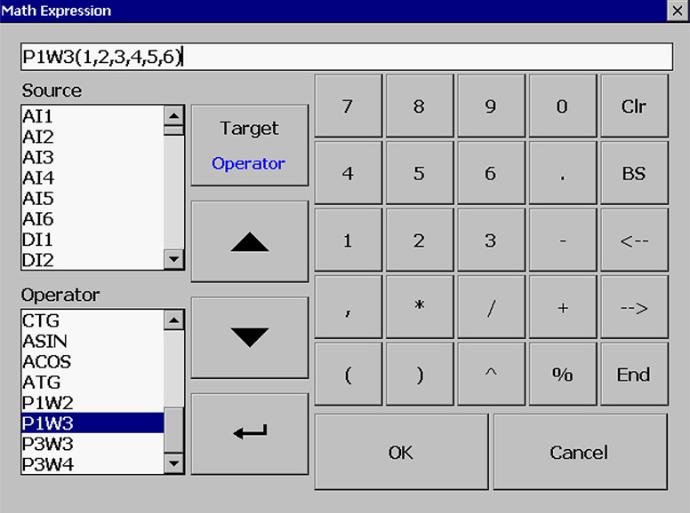

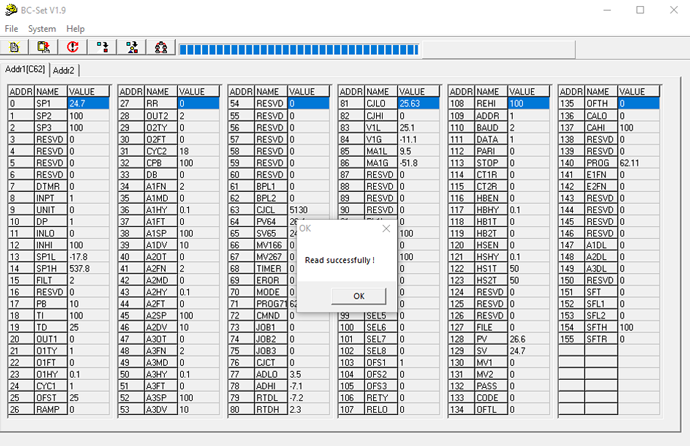

BC-SET Pro Configuration Software

Easy parameter setup, backup and firmware upgrade

BC-SET Pro is the official configuration software developed by BrainChild for its over-temperature protection controllers. With a streamlined and intuitive interface, the software allows users to connect via USB programming cable and quickly configure control parameters. It supports efficient parameter editing, setting duplication between devices, and firmware upgrades to maintain device performance and stability. BC-SET Pro also enables offline configuration with the ability to save and manage multiple profiles, making it ideal for production environments, system deployment, and ongoing maintenance. Whether for new setup or existing system adjustment, this tool helps engineers and technicians simplify workflow, reduce setup time, and ensure consistent configuration across all devices.

Batch Read/Write for Multiple Controllers

BC-SET allows users to connect multiple controllers of the same model and perform batch parameter read/write by defining a node address range. This feature significantly streamlines configuration in OEM or multi-device environments.

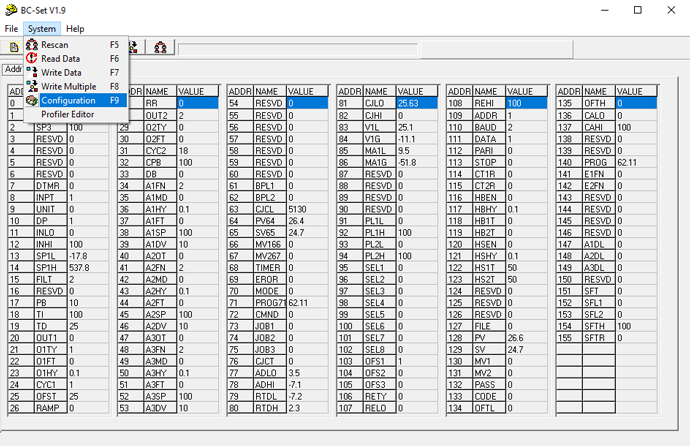

Clear and Accessible System Menu

The system menu offers quick access to key operations like Rescan (F5), Read Data (F6), Write Data (F7), Write Multiple (F8), and Communication Settings (F9). Built-in hotkeys support fast, efficient navigation.

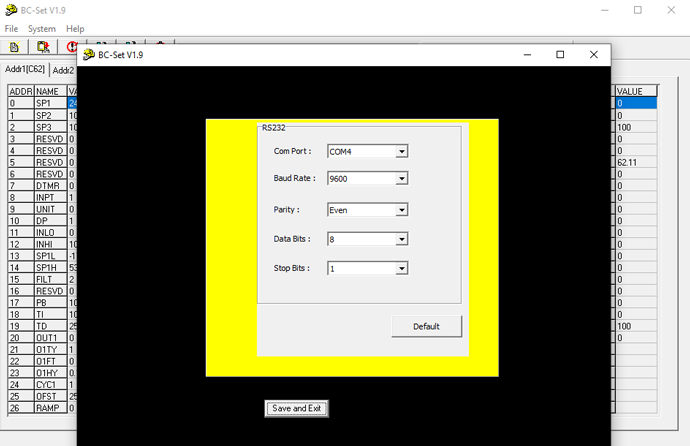

Intuitive Communication Setup Interface

The communication settings window lets users define COM port, baud rate, parity, data bits, and stop bits — with a “Default” button for quick reset and “Save and Exit” to finalize setup. Designed to reduce setup errors.

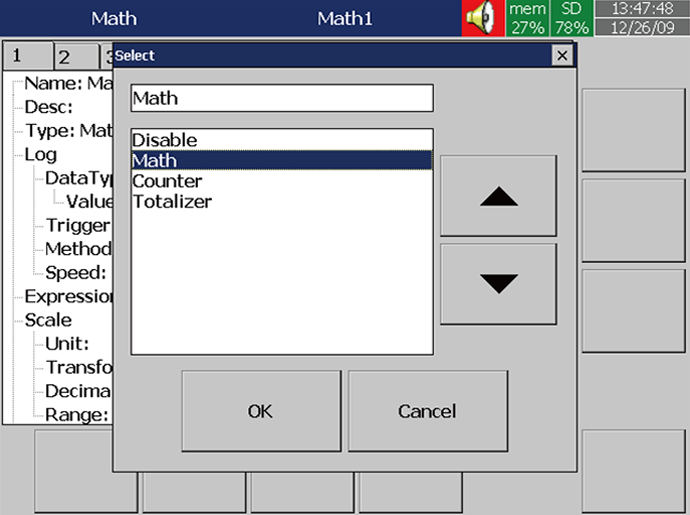

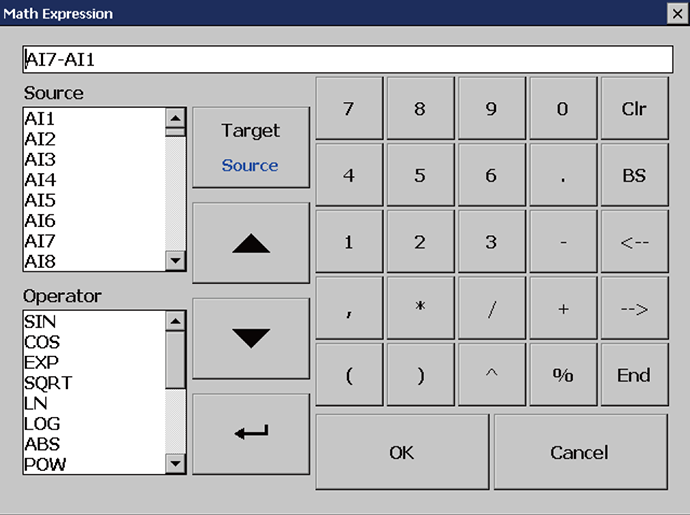

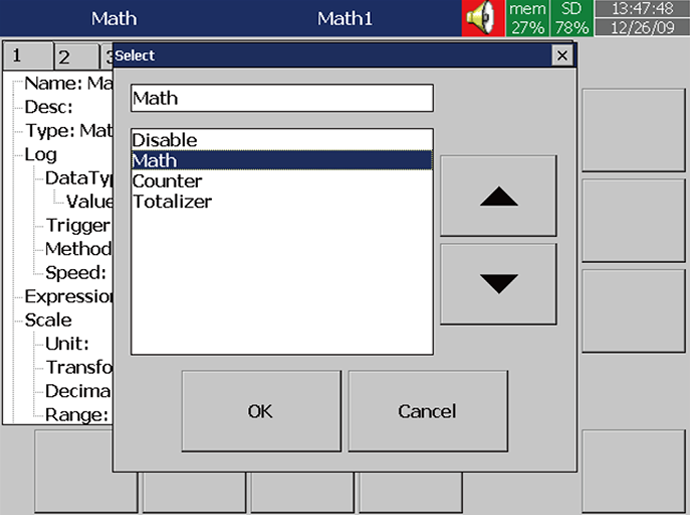

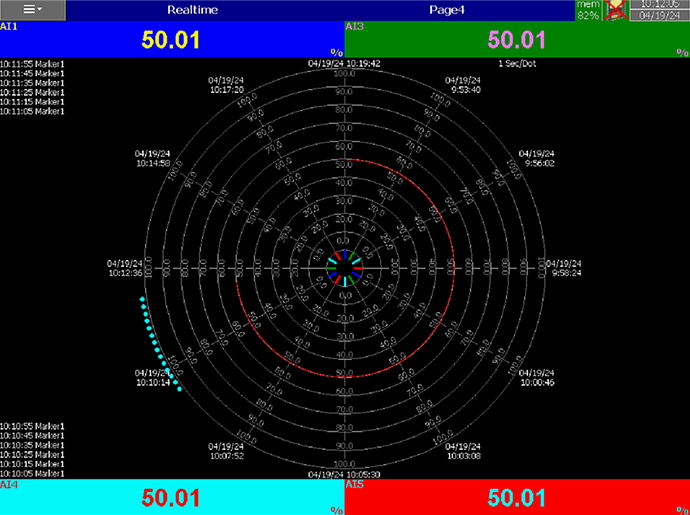

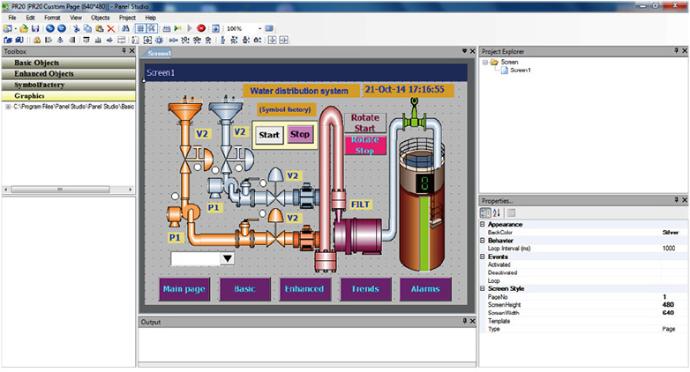

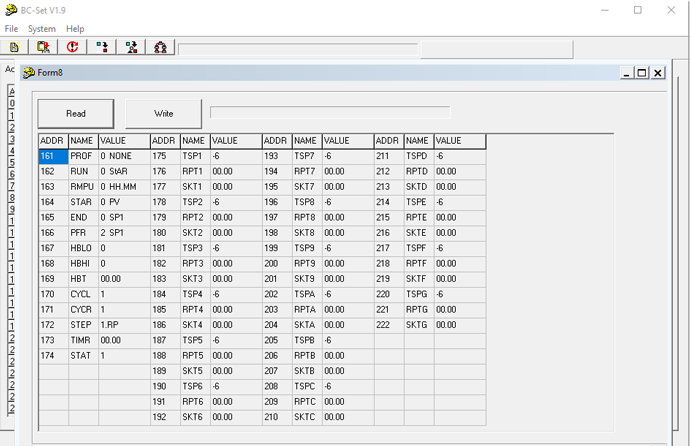

Visual Profile Editor for Programmable Controllers

For controllers with profile functionality, BC-SET provides a graphical editor to configure temperature ramp/soak segments. Users can easily read, modify, and write profile parameters for precise thermal process control.

Applications

Specification

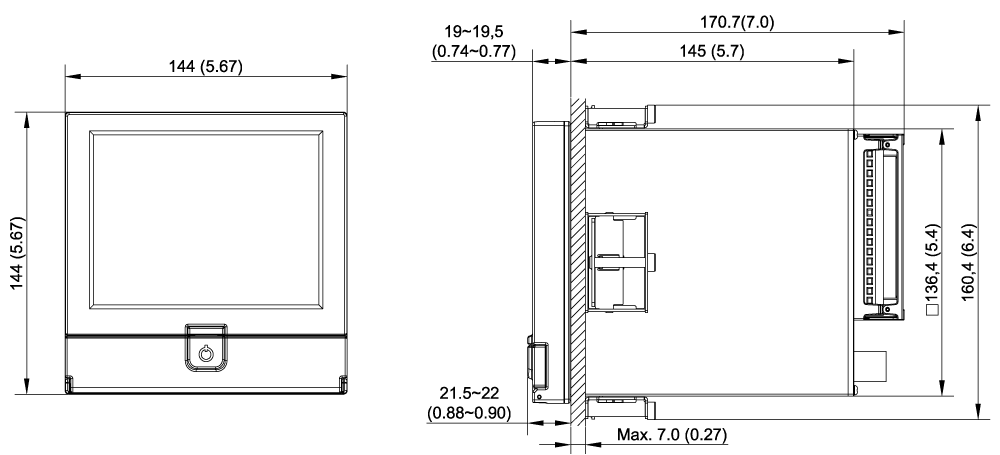

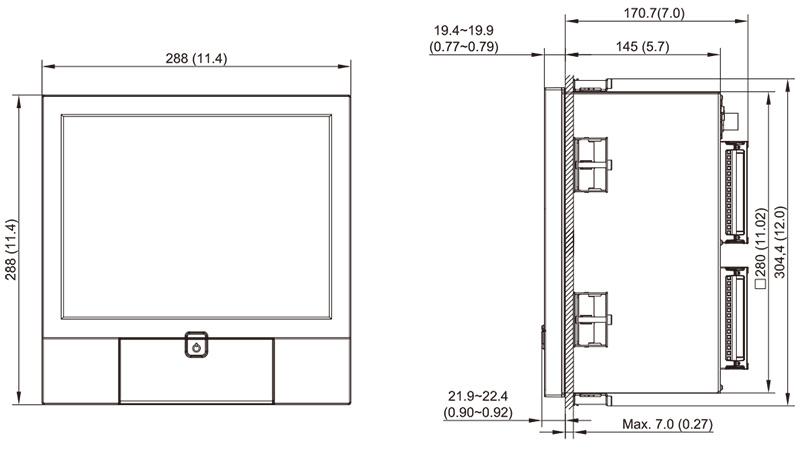

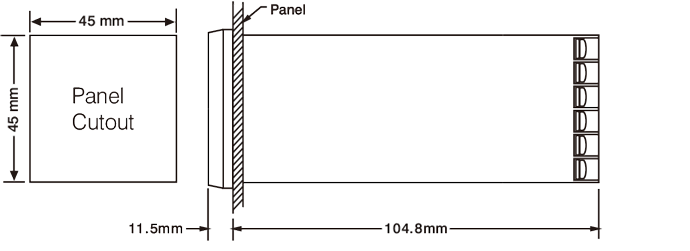

Panel Mount

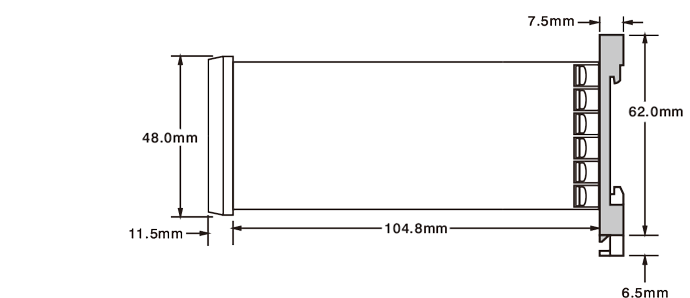

Rail Mount

Power

Signal Input

Output 1 / Output 2

Linear Output

Triac ( SSR ) Output

DC Voltage Supply Characteristics ( Installed at Output 2 )

Alarm

Data Communication

Analog Retransmission

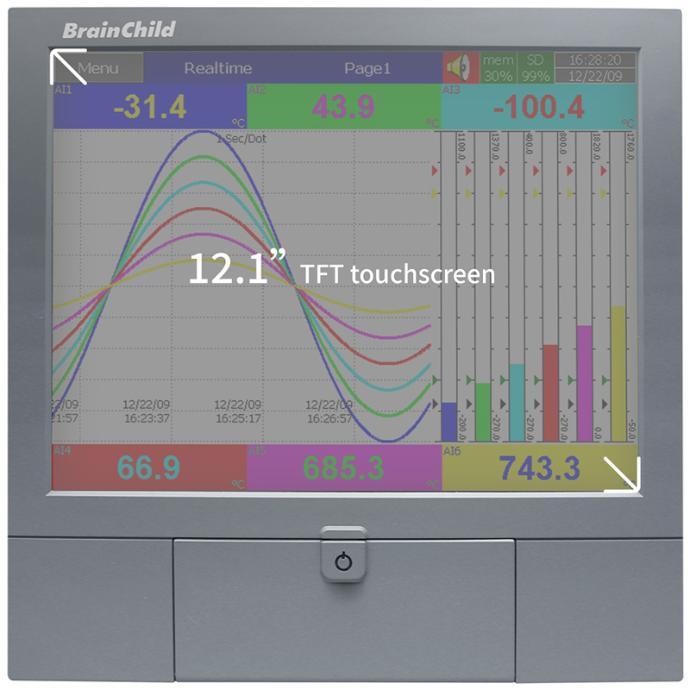

User Interface

Control Mode

Digital Filter

Event Input

Event Input

Environmental and Physical Specifications

Approval Standards

Download

Visit Download Center to See More Documents & Tools of This Product. Visit

FAQ

Yes, P91 supports 9 program profiles, each with up to 64 segments, making it ideal for precise temperature ramp/soak applications.

The P91 supports thermocouples, RTDs, voltage (mV/V), and current (mA) inputs. Input type is selectable via panel or software.

Yes, RS-485 (Modbus RTU) is available as an optional output module, enabling system integration and data transmission.

Yes, the P91 has a programming port that supports offline parameter setup, cloning, and firmware updates via PC.

When installed with a sealing gasket, the front panel achieves IP65 protection against water and dust.

Catalog_P41 & P91_EN

Catalog_P41 & P91_EN Software_BC-Set_2.0

Software_BC-Set_2.0