Features

- High-brightness dual LCD shows PV/SV and status

- 4-key panel with bidirectional menu navigation

- Auto-Tuning supports cold and warm startup modes

- Fuzzy + PID control minimizes overshoot and drift

- 18-bit A/D and 15-bit D/A ensure precise control

- Fast 200ms sampling rate for rapid process response

- Output: Relay, SSR, 4–20mA, or 0–10V selectable

- Programmable output limits and cycle timing

- RS-485 Modbus RTU for multi-unit communication

- Built-in digital filter stabilizes process readings

- Six alarm types and four alarm operating modes

- Parameter lock with four security levels

- User-defined menu with up to 8 quick-access items

- Supports TC (J/K/T/R/S) and RTD (PT100 DIN/JIS)

- CE/RoHS certified, IP50 or optional IP65 panel

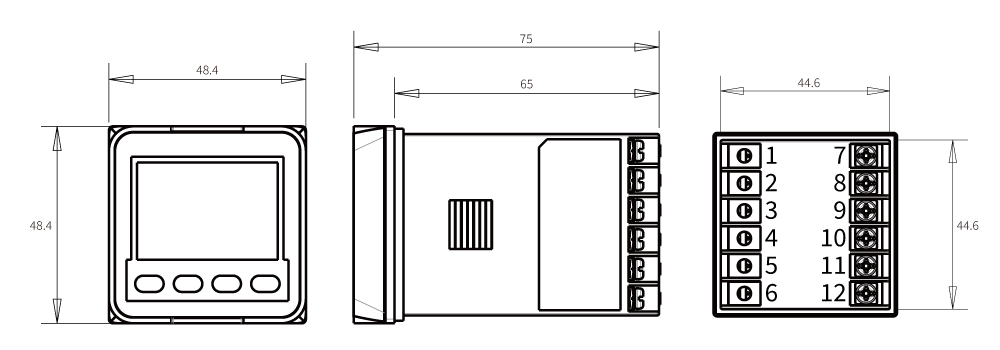

E62 PID Temperature Controller

Compact, Capable, and Cost-Effective—Precision Control Made Simple

The E62 is BrainChild’s compact PID controller designed for stable and responsive temperature control in industrial applications. It supports a wide range of TC and RTD inputs, flexible outputs (Relay, SSR, Voltage, Current), and optional RS-485 Modbus communication.

With built-in fuzzy logic, auto-tuning, alarms, and a high-brightness dual-line LCD, the E62 offers essential control performance in a user-friendly and cost-effective package—ideal for OEMs, panel builders, and system integrators.

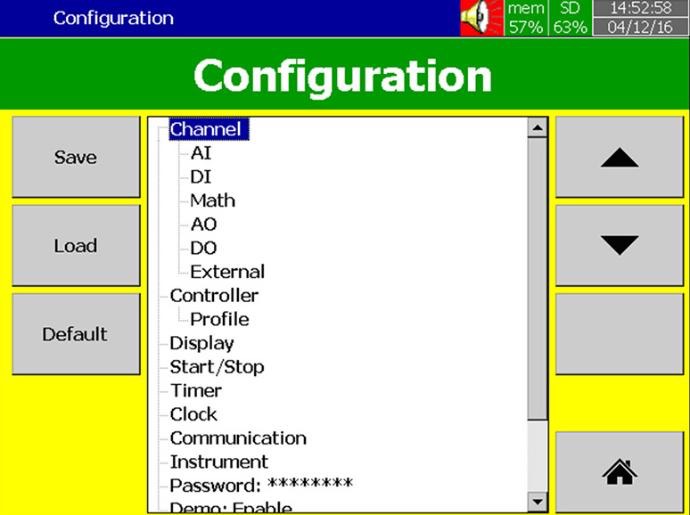

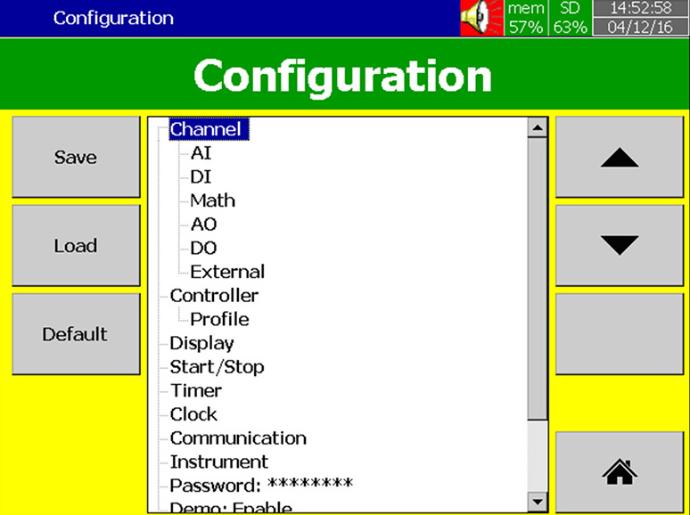

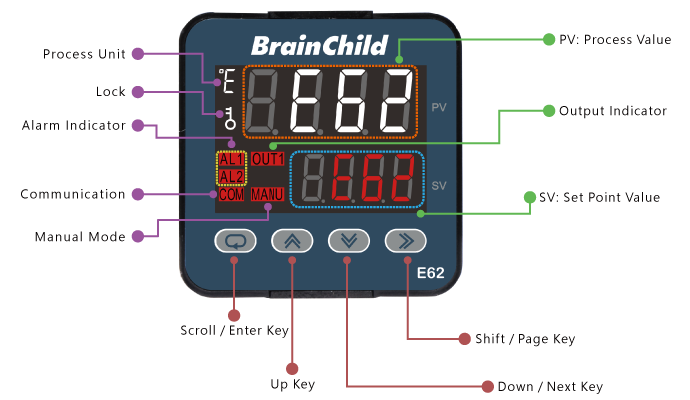

User-Friendly Interface

Intuitive Navigation, Clear Operation—Control Made Easy

The E62 controller is designed with user efficiency in mind. Featuring a high-brightness dual-line LCD and a 4-key panel layout, the interface provides clear access to process values, setpoints, and status indicators. Its bidirectional menu navigation allows users to move quickly between settings, while the customizable user menu lets you define up to 8 frequently used parameters for instant access. Whether for setup, tuning, or real-time adjustments, the E62 streamlines every step with clarity and ease.

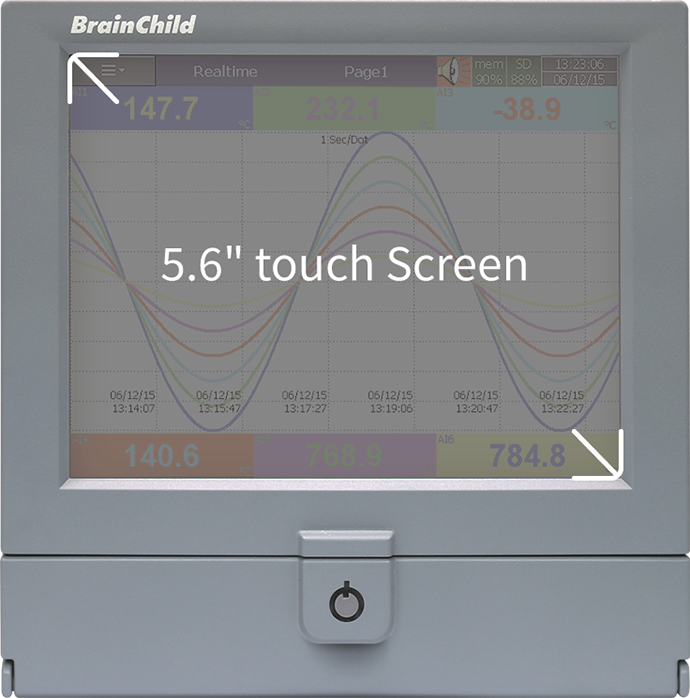

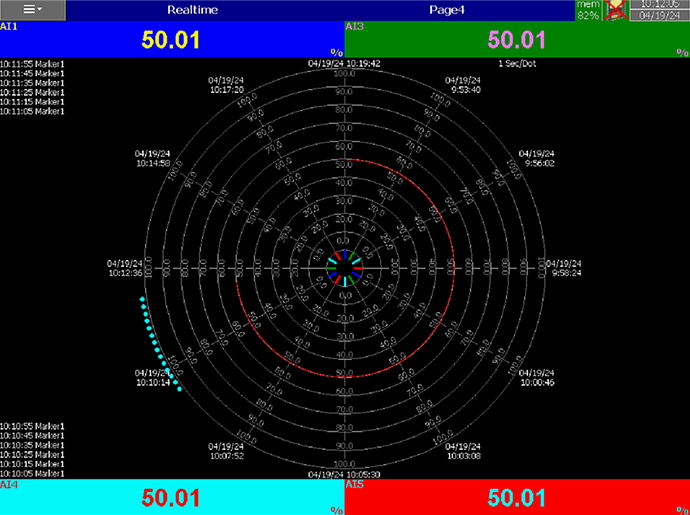

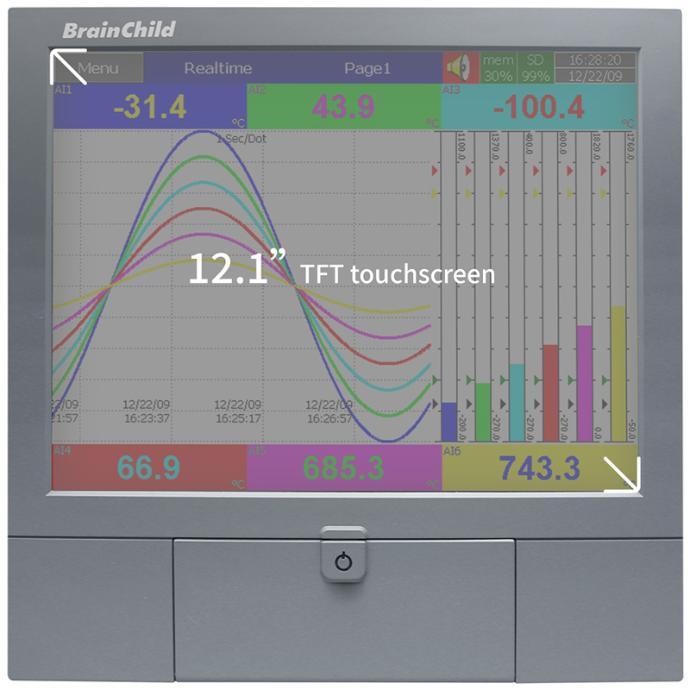

LCD Display Screen

Clear Dual-Line Readout for Instant Status Visibility

The E62 features a high-brightness dual-line LCD that clearly displays process value (PV) and setpoint (SV) in real time. This layout improves visibility during operation, even in low-light environments, and provides quick feedback for alarms, control status, and user navigation. Operators can easily monitor and adjust settings with confidence, reducing downtime and improving process efficiency.

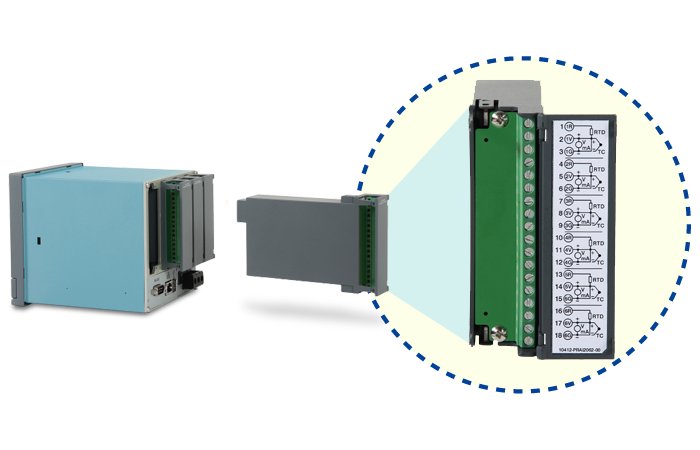

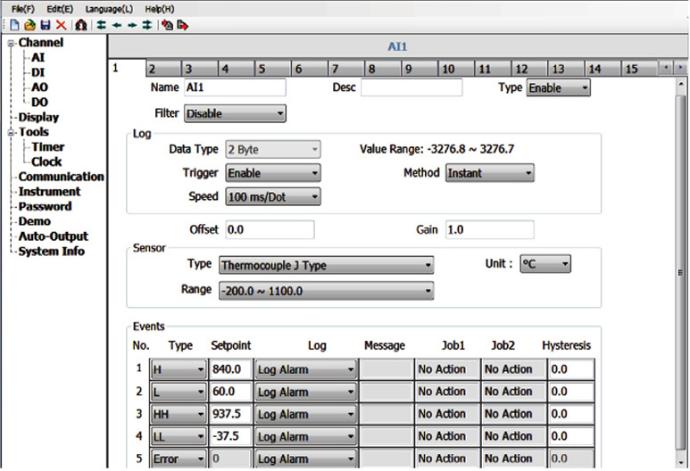

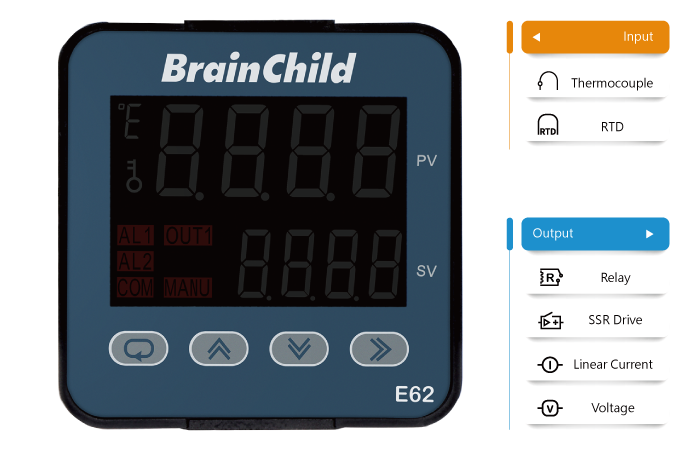

Flexible Input Compatibility

Universal Sensor Support for Maximum Application Versatility

The E62 supports a wide range of industry-standard sensors, including thermocouples (Type J, K, T, R, S) and RTDs (PT100, DIN/JIS). This flexibility ensures seamless integration across diverse thermal processes, from basic heating systems to advanced industrial applications. Whether you're retrofitting legacy equipment or building a new system, the E62 adapts easily to your sensor requirements—no extra modules needed.

Multiple Output Options to Match Your Control Needs

The E62 offers flexible output selections—including relay, SSR drive, linear current (4–20mA), and voltage (0–10V)—to suit various load types and system requirements. Whether you're driving heaters, actuators, or external controllers, the E62 delivers the signal you need for stable and accurate response.

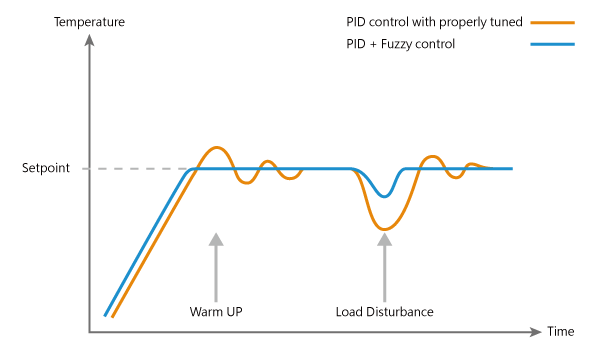

Fuzzy PID Technology

Smarter Control with Less Overshoot and Faster Response

Fuzzy logic is combined with traditional PID control to deliver smarter and more adaptive temperature regulation. Unlike standard PID controllers that require manual fine-tuning for each application, fuzzy PID dynamically adjusts control responses based on real-time process behavior. The result is faster stabilization, reduced overshoot, and improved resilience to disturbances—ideal for processes where precision and speed are critical.

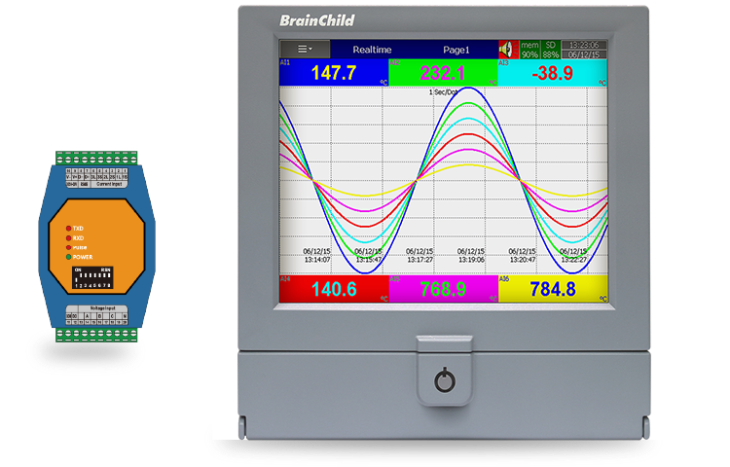

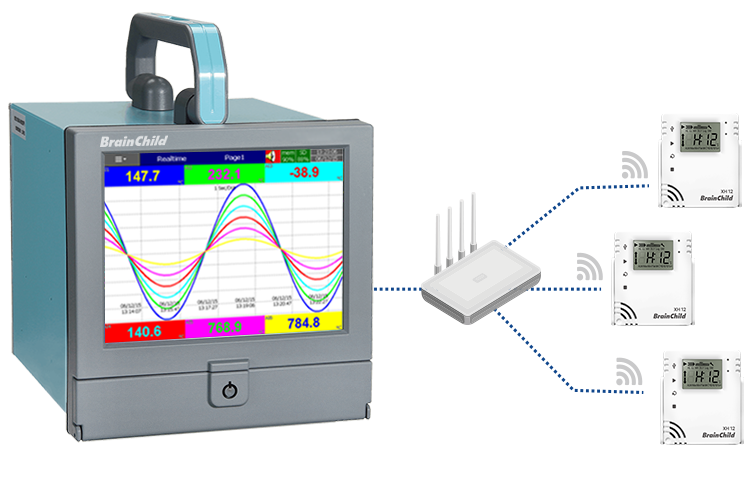

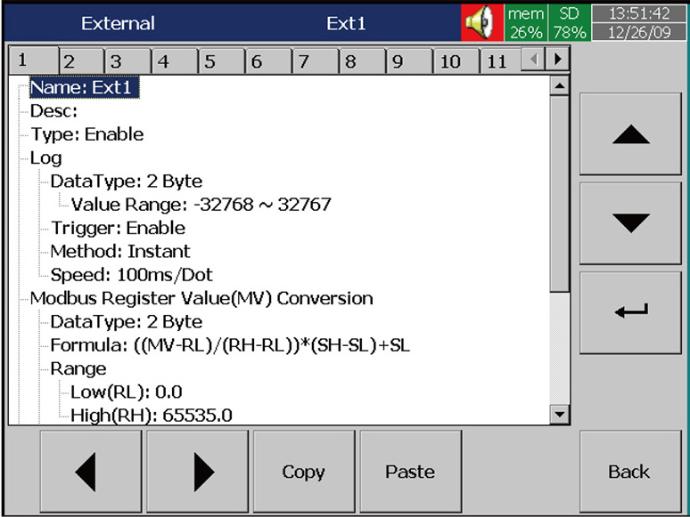

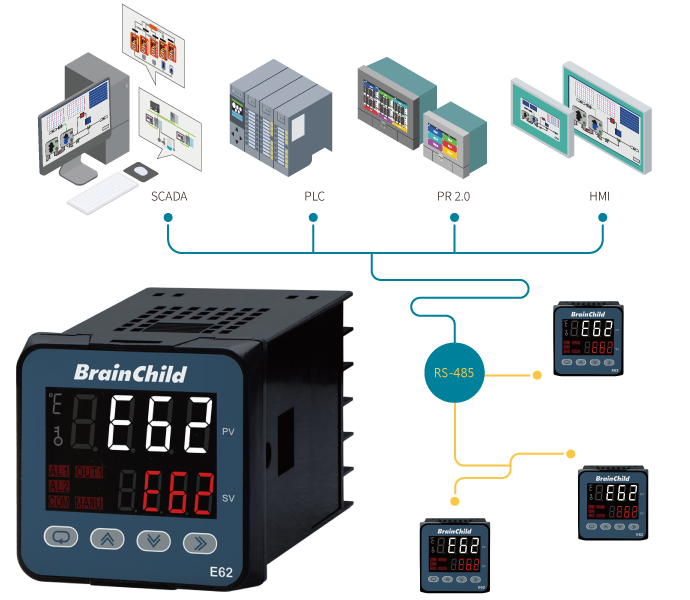

Digital Communication

Seamless Integration via RS-485 Modbus RTU Protocol

Supports RS-485 digital communication using the Modbus RTU protocol, allowing easy integration into multi-device systems such as SCADA, HMI, or PLC networks. Up to 32 devices can be linked on a single network, enabling centralized monitoring, remote control, and data logging. This ensures efficient system-wide communication and reduces wiring complexity in automation environments.

Applications

Specification

Power

Signal Input

Output

Alarm

Data Communication

User Interface

Control Mode

Digital Filter

Environmental and Physical Specifications

Approval Standards

Download

Visit Download Center to See More Documents & Tools of This Product. Visit

FAQ

The E62 supports a wide range of thermocouple types (J, K, T, R, S) and RTDs (PT100 DIN/JIS), making it suitable for various industrial temperature control applications.

Yes, the E62 features RS-485 digital communication and supports Modbus RTU (slave mode), allowing integration with SCADA, PLC, or HMI systems.

Fuzzy PID combines traditional PID with fuzzy logic, enabling the E62 to automatically adapt to process changes. It reduces overshoot, speeds up stabilization, and improves overall control accuracy.

The E62 front panel is IP50 rated by default, with an optional upgrade to IP65 for enhanced dust and water resistance in harsh industrial environments.

The E62 offers up to two alarm outputs, supporting six alarm types such as deviation high/low, in-band/out-of-band, and process high/low. Alarm modes include normal, latching, holding, and latch + hold.